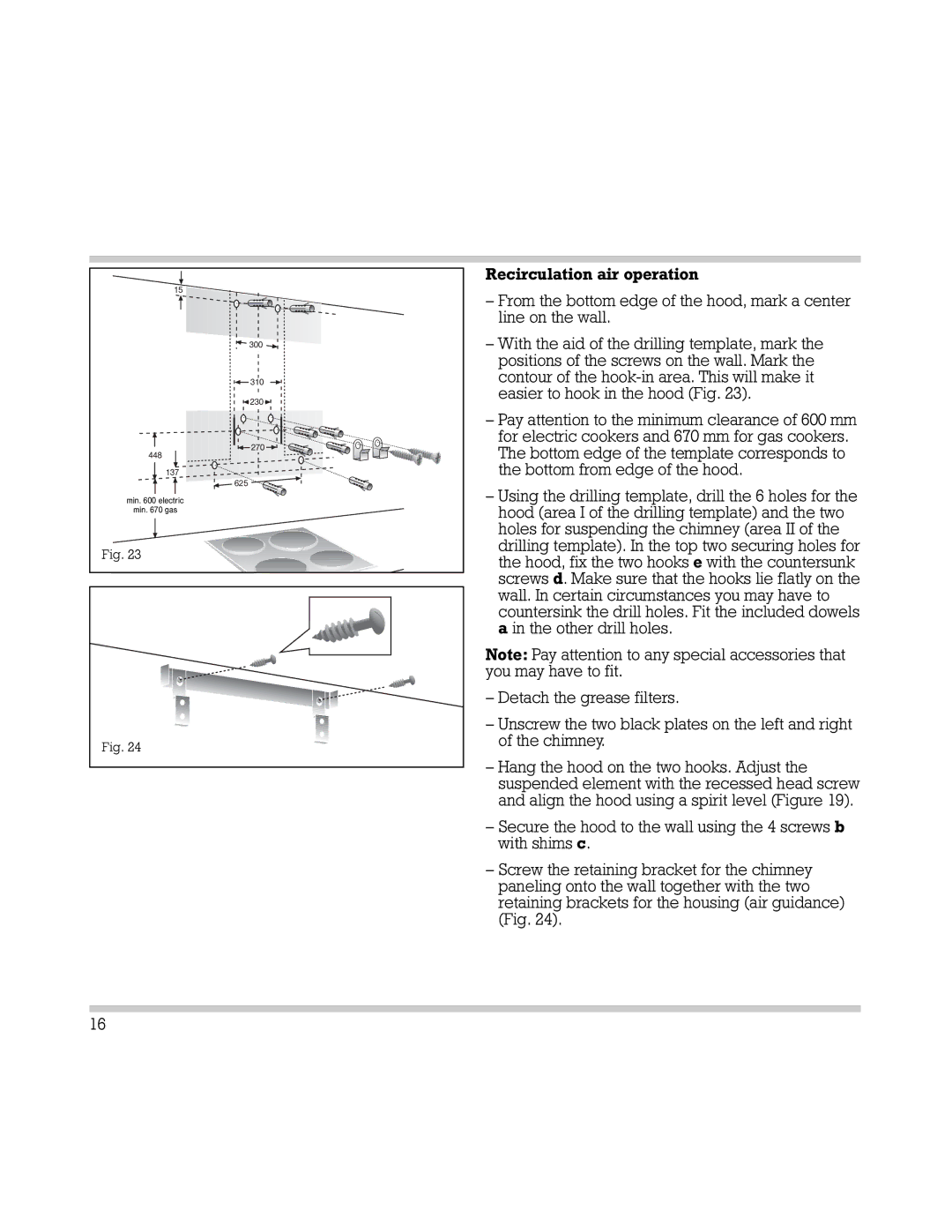

15 |

300 |

310 |

230 |

270 |

448 |

137 |

625 |

min. 600 electric |

min. 670 gas |

Fig. 23 |

Fig. 24 |

Recirculation air operation

–From the bottom edge of the hood, mark a center line on the wall.

–With the aid of the drilling template, mark the positions of the screws on the wall. Mark the contour of the

–Pay attention to the minimum clearance of 600 mm for electric cookers and 670 mm for gas cookers. The bottom edge of the template corresponds to the bottom from edge of the hood.

–Using the drilling template, drill the 6 holes for the hood (area I of the drilling template) and the two holes for suspending the chimney (area II of the drilling template). In the top two securing holes for the hood, fix the two hooks e with the countersunk screws d. Make sure that the hooks lie flatly on the wall. In certain circumstances you may have to countersink the drill holes. Fit the included dowels a in the other drill holes.

Note: Pay attention to any special accessories that you may have to fit.

–Detach the grease filters.

–Unscrew the two black plates on the left and right of the chimney.

–Hang the hood on the two hooks. Adjust the suspended element with the recessed head screw and align the hood using a spirit level (Figure 19).

–Secure the hood to the wall using the 4 screws b with shims c.

–Screw the retaining bracket for the chimney paneling onto the wall together with the two retaining brackets for the housing (air guidance) (Fig. 24).

16