Section 4 — Maintenance

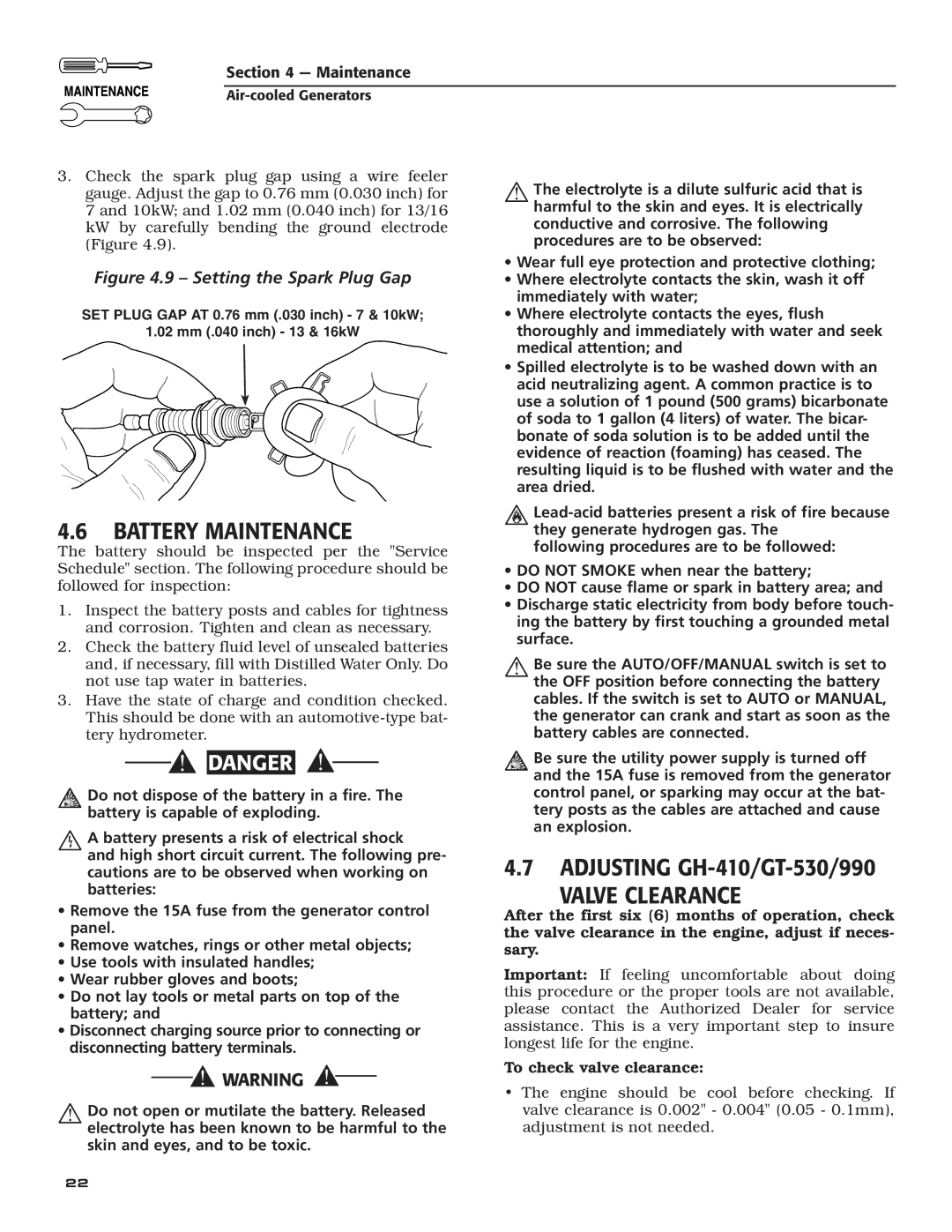

3.Check the spark plug gap using a wire feeler gauge. Adjust the gap to 0.76 mm (0.030 inch) for 7 and 10kW; and 1.02 mm (0.040 inch) for 13/16 kW by carefully bending the ground electrode (Figure 4.9).

Figure 4.9 – Setting the Spark Plug Gap

SET PLUG GAP AT 0.76 mm (.030 inch) - 7 & 10kW;

![]() 1.02 mm (.040 inch) - 13

1.02 mm (.040 inch) - 13![]() & 16kW

& 16kW

4.6BATTERY MAINTENANCE

The battery should be inspected per the "Service Schedule" section. The following procedure should be followed for inspection:

1.Inspect the battery posts and cables for tightness and corrosion. Tighten and clean as necessary.

2.Check the battery fluid level of unsealed batteries and, if necessary, fill with Distilled Water Only. Do not use tap water in batteries.

3.Have the state of charge and condition checked. This should be done with an

![]()

![]() DANGER

DANGER

Do not dispose of the battery in a fire. The battery is capable of exploding.

A battery presents a risk of electrical shock

and high short circuit current. The following pre- cautions are to be observed when working on batteries:

•Remove the 15A fuse from the generator control panel.

•Remove watches, rings or other metal objects;

•Use tools with insulated handles;

•Wear rubber gloves and boots;

•Do not lay tools or metal parts on top of the battery; and

•Disconnect charging source prior to connecting or disconnecting battery terminals.

Do not open or mutilate the battery. Released electrolyte has been known to be harmful to the skin and eyes, and to be toxic.

22

The electrolyte is a dilute sulfuric acid that is harmful to the skin and eyes. It is electrically conductive and corrosive. The following procedures are to be observed:

•Wear full eye protection and protective clothing;

•Where electrolyte contacts the skin, wash it off immediately with water;

•Where electrolyte contacts the eyes, flush thoroughly and immediately with water and seek medical attention; and

•Spilled electrolyte is to be washed down with an acid neutralizing agent. A common practice is to use a solution of 1 pound (500 grams) bicarbonate of soda to 1 gallon (4 liters) of water. The bicar- bonate of soda solution is to be added until the evidence of reaction (foaming) has ceased. The resulting liquid is to be flushed with water and the area dried.

following procedures are to be followed:

•DO NOT SMOKE when near the battery;

•DO NOT cause flame or spark in battery area; and

•Discharge static electricity from body before touch- ing the battery by first touching a grounded metal surface.

Be sure the AUTO/OFF/MANUAL switch is set to the OFF position before connecting the battery cables. If the switch is set to AUTO or MANUAL, the generator can crank and start as soon as the battery cables are connected.

Be sure the utility power supply is turned off and the 15A fuse is removed from the generator control panel, or sparking may occur at the bat- tery posts as the cables are attached and cause an explosion.

4.7ADJUSTING

VALVE CLEARANCE

After the first six (6) months of operation, check the valve clearance in the engine, adjust if neces- sary.

Important: If feeling uncomfortable about doing this procedure or the proper tools are not available, please contact the Authorized Dealer for service assistance. This is a very important step to insure longest life for the engine.

To check valve clearance:

•The engine should be cool before checking. If valve clearance is 0.002" - 0.004" (0.05 - 0.1mm), adjustment is not needed.