Section 1 — General Information

1.6SYSTEM SET LED

The “System Set” LED is lit when all of the following conditions are true:

1.The AUTO/OFF/MANUAL switch is set to the AUTO position.

2.The utility voltage being supplied to the unit is being sensed by the PCB. If the utility sense volt- age is not connected to the unit or if it is below approximately

3.No alarms are present, for example, low oil pres- sure, high temperature, etc.

1.7FUEL REQUIREMENTS

AND RECOMMENDATIONS

With LP gas, use only the vapor withdrawal sys- tem. This type of system uses the vapors formed above the liquid fuel in the storage tank.

The engine has been fitted with a fuel carburetion system that meets the specifications of the 1997 California Air Resources Board for

Recommended fuels should have a Btu content of at least 1,000 Btus per cubic foot for natural gas; or at least 2,520 Btus per cubic foot for LP gas. Ask the fuel supplier for the Btu content of the fuel.

Required fuel pressure for natural gas is 5 inches to 7 inches water column (0.18 to 0.25 psi); and for liquid propane, 10 inches to 12 inches of water column (0.36 to 0.43 psi).

NOTE:

All pipe sizing, construction and layout must com- ply with NFPA 54 for natural gas applications and NFPA 58 for liquid propane applications. Once the generator is installed, verify that the fuel pressure NEVER drops below four (4) inches water column for natural gas or 10 inches water column for liq- uid propane.

Prior to installation of the generator, the installer should consult local fuel suppliers or the fire mar- shall to check codes and regulations for proper installation. Local codes will mandate correct routing of gaseous fuel line piping around gardens, shrubs and other landscaping to prevent any damage.

Special considerations should be given when install- ing the unit where local conditions include flooding, tornados, hurricanes, earthquakes and unstable ground for the flexibility and strength of piping and their connections.

Use an approved pipe sealant or joint compound on all threaded fitting.

All installed gaseous fuel piping must be purged and leak tested prior to initial

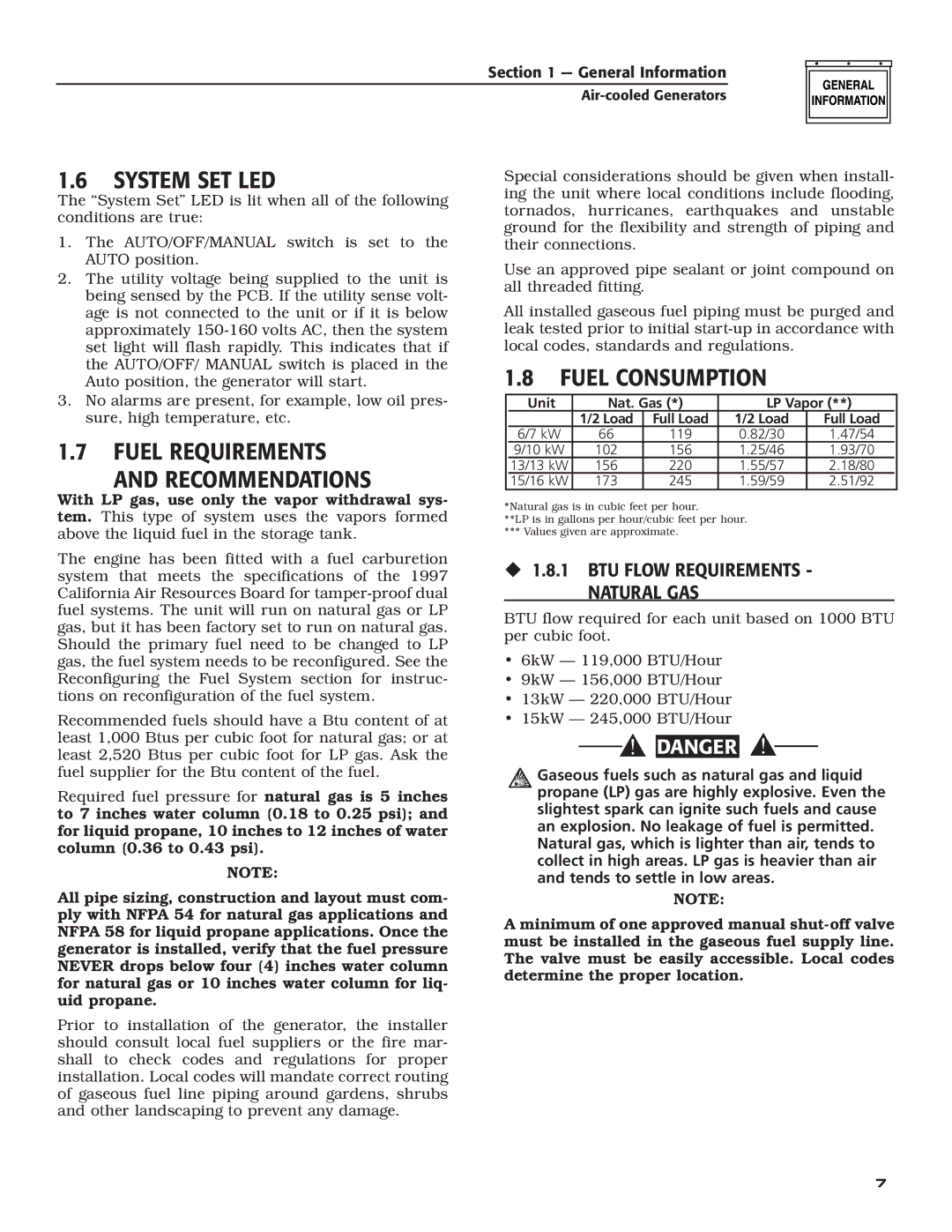

1.8FUEL CONSUMPTION

| Unit | Nat. Gas (*) | LP Vapor (**) |

| ||

|

| 1/2 Load | Full Load | 1/2 Load | Full Load |

|

| 6/7 kW | 66 | 119 | 0.82/30 | 1.47/54 |

|

| 9/10 kW | 102 | 156 | 1.25/46 | 1.93/70 |

|

| 13/13 kW | 156 | 220 | 1.55/57 | 2.18/80 |

|

| 15/16 kW | 173 | 245 | 1.59/59 | 2.51/92 |

|

*Natural gas is in cubic feet per hour.

**LP is in gallons per hour/cubic feet per hour.

*** Values given are approximate.

1.8.1 BTU FLOW REQUIREMENTS -

NATURAL GAS

BTU flow required for each unit based on 1000 BTU per cubic foot.

•6kW — 119,000 BTU/Hour

•9kW — 156,000 BTU/Hour

•13kW — 220,000 BTU/Hour

•15kW — 245,000 BTU/Hour

![]()

![]() DANGER

DANGER

Gaseous fuels such as natural gas and liquid propane (LP) gas are highly explosive. Even the slightest spark can ignite such fuels and cause an explosion. No leakage of fuel is permitted. Natural gas, which is lighter than air, tends to collect in high areas. LP gas is heavier than air and tends to settle in low areas.

NOTE:

A minimum of one approved manual

7