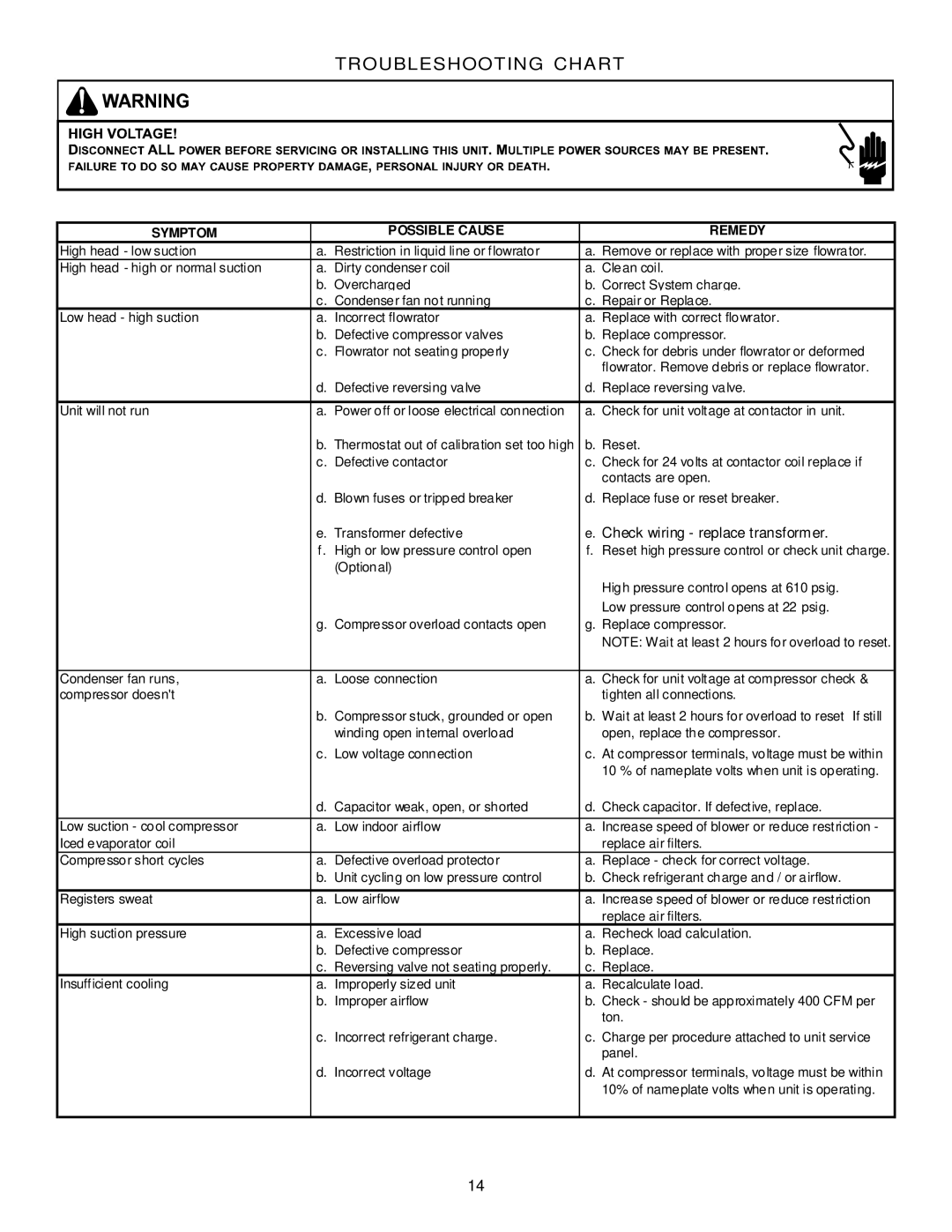

TROUBLESHOOTING CHART

SYMPTOM | POSSIBLE CAUSE | REMEDY |

High head - low suction | a. Restriction in liquid line or flowrator | a. Remove or replace with proper size flowrator. |

High head - high or normal suction | a. Dirty condenser coil | a. Clean coil. |

| b. Overcharged | b. Correct System charge. |

| c. Condenser fan not running | c. Repair or Replace. |

Low head - high suction | a. Incorrect flowrator | a. Replace with correct flowrator. |

| b. Defective compressor valves | b. Replace compressor. |

| c. Flowrator not seating properly | c. Check for debris under flowrator or deformed |

|

| flowrator. Remove debris or replace flowrator. |

| d. Defective reversing valve | d. Replace reversing valve. |

|

|

|

Unit will not run | a. Power off or loose electrical connection | a. Check for unit voltage at contactor in unit. |

| b. Thermostat out of calibration set too high | b. Reset. |

| c. Defective contactor | c. Check for 24 volts at contactor coil replace if |

|

| contacts are open. |

| d. Blown fuses or tripped breaker | d. Replace fuse or reset breaker. |

| e. Transformer defective | e. Check wiring - replace transformer. |

| f. High or low pressure control open | f. Reset high pressure control or check unit charge. |

| (Optional) |

|

|

| High pressure control opens at 610 psig. |

|

| Low pressure control opens at 22 psig. |

| g. Compressor overload contacts open | g. Replace compressor. |

|

| NOTE: Wait at least 2 hours for overload to reset. |

|

|

|

Condenser fan runs, | a. Loose connection | a. Check for unit voltage at compressor check & |

compressor doesn't |

| tighten all connections. |

| b. Compressor stuck, grounded or open | b. Wait at least 2 hours for overload to reset If still |

| winding open internal overload | open, replace the compressor. |

| c. Low voltage connection | c. At compressor terminals, voltage must be within |

|

| 10 % of nameplate volts when unit is operating. |

| d. Capacitor weak, open, or shorted | d. Check capacitor. If defective, replace. |

|

|

|

Low suction - cool compressor | a. Low indoor airflow | a. Increase speed of blower or reduce restriction - |

Iced evaporator coil |

| replace air filters. |

Compressor short cycles | a. Defective overload protector | a. Replace - check for correct voltage. |

| b. Unit cycling on low pressure control | b. Check refrigerant charge and / or airflow. |

|

|

|

Registers sweat | a. Low airflow | a. Increase speed of blower or reduce restriction |

|

| replace air filters. |

High suction pressure | a. Excessive load | a. Recheck load calculation. |

| b. Defective compressor | b. Replace. |

| c. Reversing valve not seating properly. | c. Replace. |

Insufficient cooling | a. Improperly sized unit | a. Recalculate load. |

| b. Improper airflow | b. Check - should be approximately 400 CFM per |

|

| ton. |

| c. Incorrect refrigerant charge. | c. Charge per procedure attached to unit service |

|

| panel. |

| d. Incorrect voltage | d. At compressor terminals, voltage must be within |

|

| 10% of nameplate volts when unit is operating. |

|

|

|

14