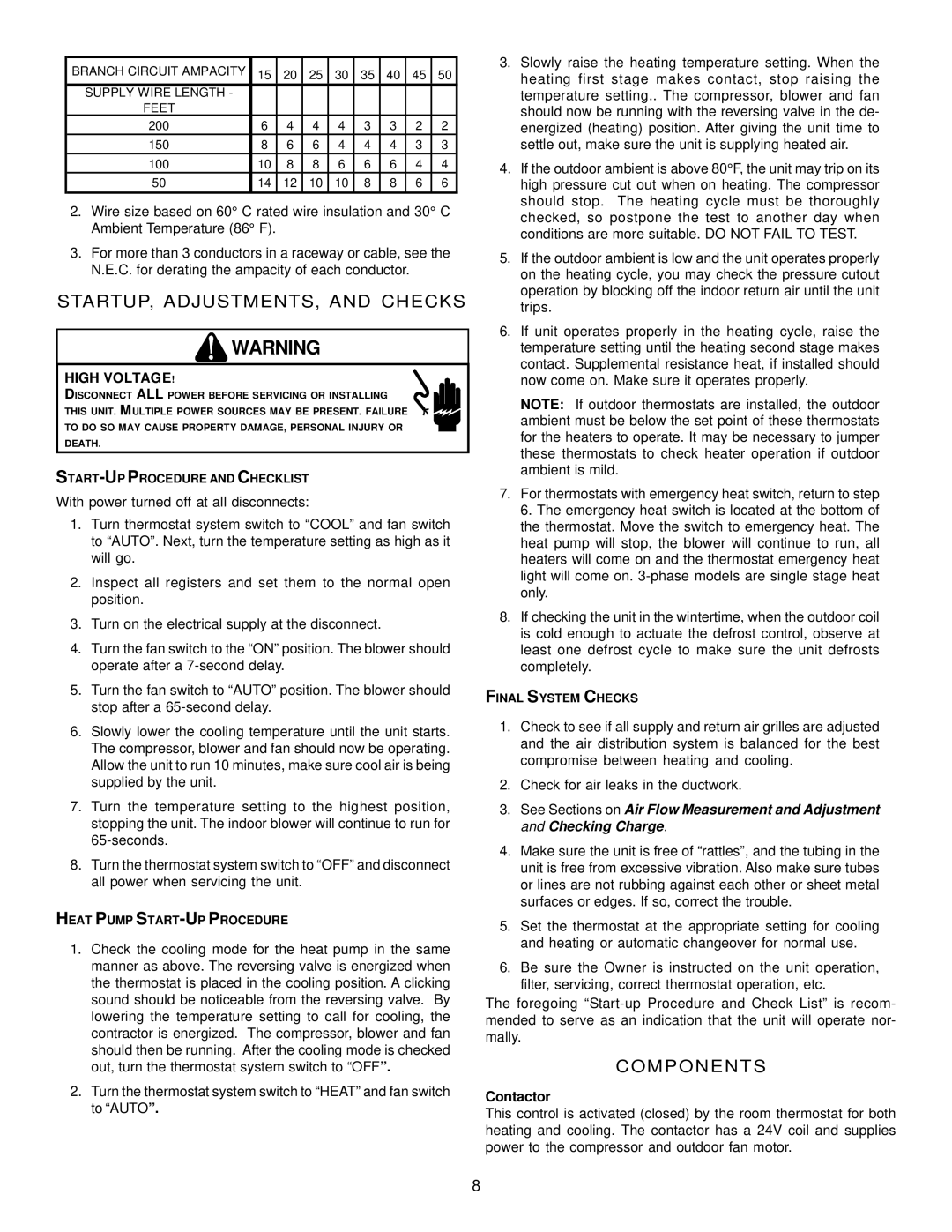

BRANCH CIRCUIT AMPACITY | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 |

SUPPLY WIRE LENGTH - |

|

|

|

|

|

|

|

|

FEET |

|

|

|

|

|

|

|

|

200 | 6 | 4 | 4 | 4 | 3 | 3 | 2 | 2 |

150 | 8 | 6 | 6 | 4 | 4 | 4 | 3 | 3 |

100 | 10 | 8 | 8 | 6 | 6 | 6 | 4 | 4 |

50 | 14 | 12 | 10 | 10 | 8 | 8 | 6 | 6 |

2.Wire size based on 60° C rated wire insulation and 30° C Ambient Temperature (86° F).

3.For more than 3 conductors in a raceway or cable, see the N.E.C. for derating the ampacity of each conductor.

STARTUP, ADJUSTMENTS, AND CHECKS

![]() WARNING

WARNING

HIGH VOLTAGE!

DISCONNECT ALL POWER BEFORE SERVICING OR INSTALLING THIS UNIT. MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO DO SO MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

START-UP PROCEDURE AND CHECKLIST

With power turned off at all disconnects:

1.Turn thermostat system switch to “COOL” and fan switch to “AUTO”. Next, turn the temperature setting as high as it will go.

2.Inspect all registers and set them to the normal open position.

3.Turn on the electrical supply at the disconnect.

4.Turn the fan switch to the “ON” position. The blower should operate after a

5.Turn the fan switch to “AUTO” position. The blower should stop after a

6.Slowly lower the cooling temperature until the unit starts. The compressor, blower and fan should now be operating. Allow the unit to run 10 minutes, make sure cool air is being supplied by the unit.

7.Turn the temperature setting to the highest position, stopping the unit. The indoor blower will continue to run for

8.Turn the thermostat system switch to “OFF” and disconnect all power when servicing the unit.

HEAT PUMP START-UP PROCEDURE

1.Check the cooling mode for the heat pump in the same manner as above. The reversing valve is energized when the thermostat is placed in the cooling position. A clicking sound should be noticeable from the reversing valve. By lowering the temperature setting to call for cooling, the contractor is energized. The compressor, blower and fan should then be running. After the cooling mode is checked out, turn the thermostat system switch to “OFF”.

2.Turn the thermostat system switch to “HEAT” and fan switch to “AUTO”.

3.Slowly raise the heating temperature setting. When the heating first stage makes contact, stop raising the temperature setting.. The compressor, blower and fan should now be running with the reversing valve in the de- energized (heating) position. After giving the unit time to settle out, make sure the unit is supplying heated air.

4.If the outdoor ambient is above 80°F, the unit may trip on its high pressure cut out when on heating. The compressor should stop. The heating cycle must be thoroughly checked, so postpone the test to another day when conditions are more suitable. DO NOT FAIL TO TEST.

5.If the outdoor ambient is low and the unit operates properly on the heating cycle, you may check the pressure cutout operation by blocking off the indoor return air until the unit trips.

6.If unit operates properly in the heating cycle, raise the temperature setting until the heating second stage makes contact. Supplemental resistance heat, if installed should now come on. Make sure it operates properly.

NOTE: If outdoor thermostats are installed, the outdoor ambient must be below the set point of these thermostats for the heaters to operate. It may be necessary to jumper these thermostats to check heater operation if outdoor ambient is mild.

7.For thermostats with emergency heat switch, return to step 6. The emergency heat switch is located at the bottom of the thermostat. Move the switch to emergency heat. The heat pump will stop, the blower will continue to run, all heaters will come on and the thermostat emergency heat light will come on.

8.If checking the unit in the wintertime, when the outdoor coil is cold enough to actuate the defrost control, observe at least one defrost cycle to make sure the unit defrosts completely.

FINAL SYSTEM CHECKS

1.Check to see if all supply and return air grilles are adjusted and the air distribution system is balanced for the best compromise between heating and cooling.

2.Check for air leaks in the ductwork.

3.See Sections on Air Flow Measurement and Adjustment and Checking Charge.

4.Make sure the unit is free of “rattles”, and the tubing in the unit is free from excessive vibration. Also make sure tubes or lines are not rubbing against each other or sheet metal surfaces or edges. If so, correct the trouble.

5.Set the thermostat at the appropriate setting for cooling and heating or automatic changeover for normal use.

6.Be sure the Owner is instructed on the unit operation, filter, servicing, correct thermostat operation, etc.

The foregoing

COMPONENTS

Contactor

This control is activated (closed) by the room thermostat for both heating and cooling. The contactor has a 24V coil and supplies power to the compressor and outdoor fan motor.

8