ASPF Model | Insulation Kit |

|

|

1830 | |

|

|

3137 / 4260 |

Table 8

The following describes converting to “Horizontal

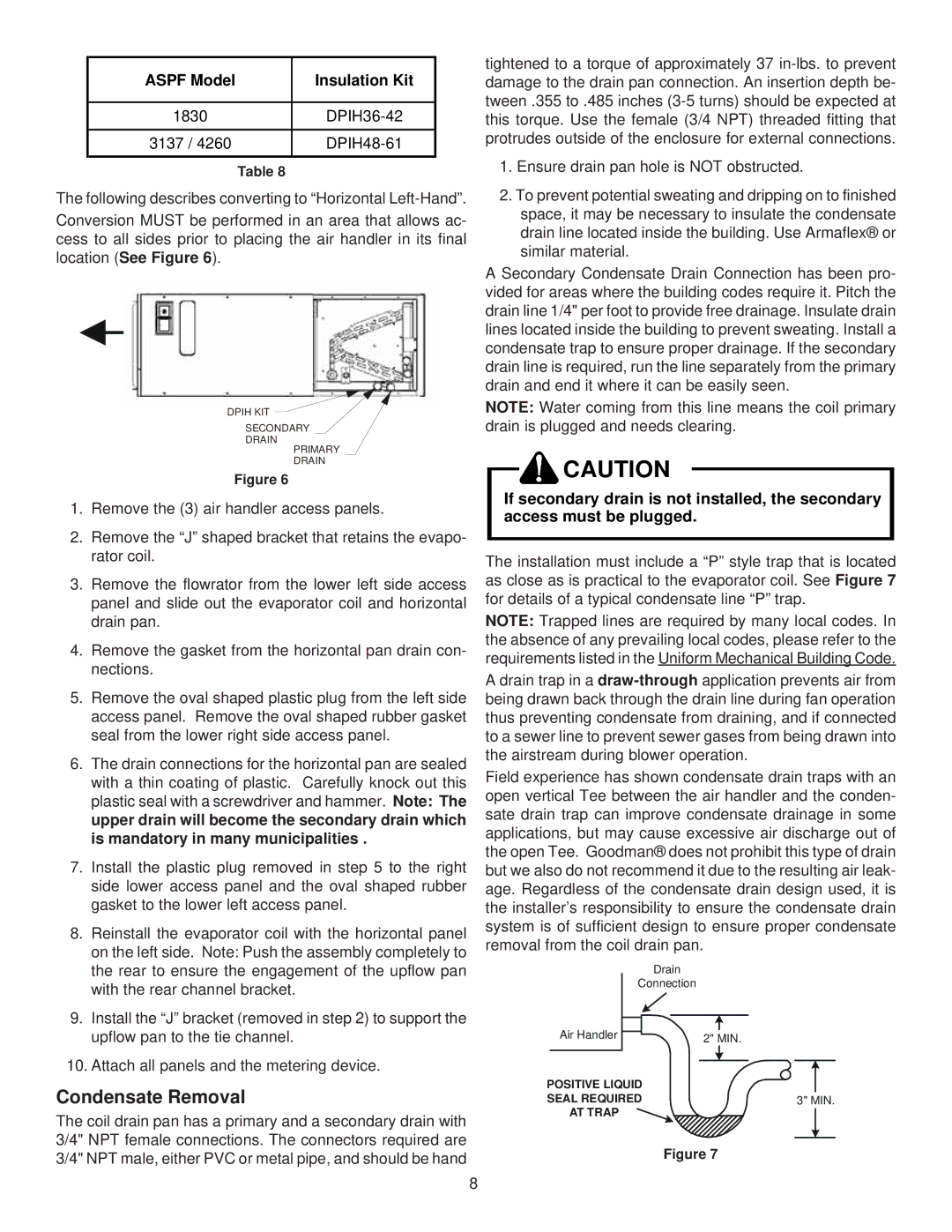

Conversion MUST be performed in an area that allows ac- cess to all sides prior to placing the air handler in its final location (See Figure 6).

DPIH KIT ![]()

SECONDARY

DRAIN

PRIMARY

DRAIN

Figure 6

1.Remove the (3) air handler access panels.

2.Remove the “J” shaped bracket that retains the evapo- rator coil.

3.Remove the flowrator from the lower left side access panel and slide out the evaporator coil and horizontal drain pan.

4.Remove the gasket from the horizontal pan drain con- nections.

5.Remove the oval shaped plastic plug from the left side access panel. Remove the oval shaped rubber gasket seal from the lower right side access panel.

6.The drain connections for the horizontal pan are sealed with a thin coating of plastic. Carefully knock out this plastic seal with a screwdriver and hammer. Note: The upper drain will become the secondary drain which is mandatory in many municipalities .

7.Install the plastic plug removed in step 5 to the right side lower access panel and the oval shaped rubber gasket to the lower left access panel.

8.Reinstall the evaporator coil with the horizontal panel on the left side. Note: Push the assembly completely to the rear to ensure the engagement of the upflow pan with the rear channel bracket.

9.Install the “J” bracket (removed in step 2) to support the upflow pan to the tie channel.

10. Attach all panels and the metering device.

Condensate Removal

The coil drain pan has a primary and a secondary drain with 3/4" NPT female connections. The connectors required are 3/4" NPT male, either PVC or metal pipe, and should be hand

tightened to a torque of approximately 37

1.Ensure drain pan hole is NOT obstructed.

2.To prevent potential sweating and dripping on to finished space, it may be necessary to insulate the condensate drain line located inside the building. Use Armaflex® or similar material.

A Secondary Condensate Drain Connection has been pro- vided for areas where the building codes require it. Pitch the drain line 1/4" per foot to provide free drainage. Insulate drain lines located inside the building to prevent sweating. Install a condensate trap to ensure proper drainage. If the secondary drain line is required, run the line separately from the primary drain and end it where it can be easily seen.

NOTE: Water coming from this line means the coil primary drain is plugged and needs clearing.

![]() CAUTION

CAUTION

If secondary drain is not installed, the secondary access must be plugged.

The installation must include a “P” style trap that is located as close as is practical to the evaporator coil. See Figure 7 for details of a typical condensate line “P” trap.

NOTE: Trapped lines are required by many local codes. In the absence of any prevailing local codes, please refer to the requirements listed in the Uniform Mechanical Building Code.

Adrain trap in a

Field experience has shown condensate drain traps with an open vertical Tee between the air handler and the conden- sate drain trap can improve condensate drainage in some applications, but may cause excessive air discharge out of the open Tee. Goodman® does not prohibit this type of drain but we also do not recommend it due to the resulting air leak- age. Regardless of the condensate drain design used, it is the installer’s responsibility to ensure the condensate drain system is of sufficient design to ensure proper condensate removal from the coil drain pan.

Drain |

|

Connection |

|

Air Handler | 2" MIN. |

POSITIVE LIQUID |

|

SEAL REQUIRED | 3" MIN. |

AT TRAP |

|

Figure 7

8