Pressure Relief

Pressure Relief

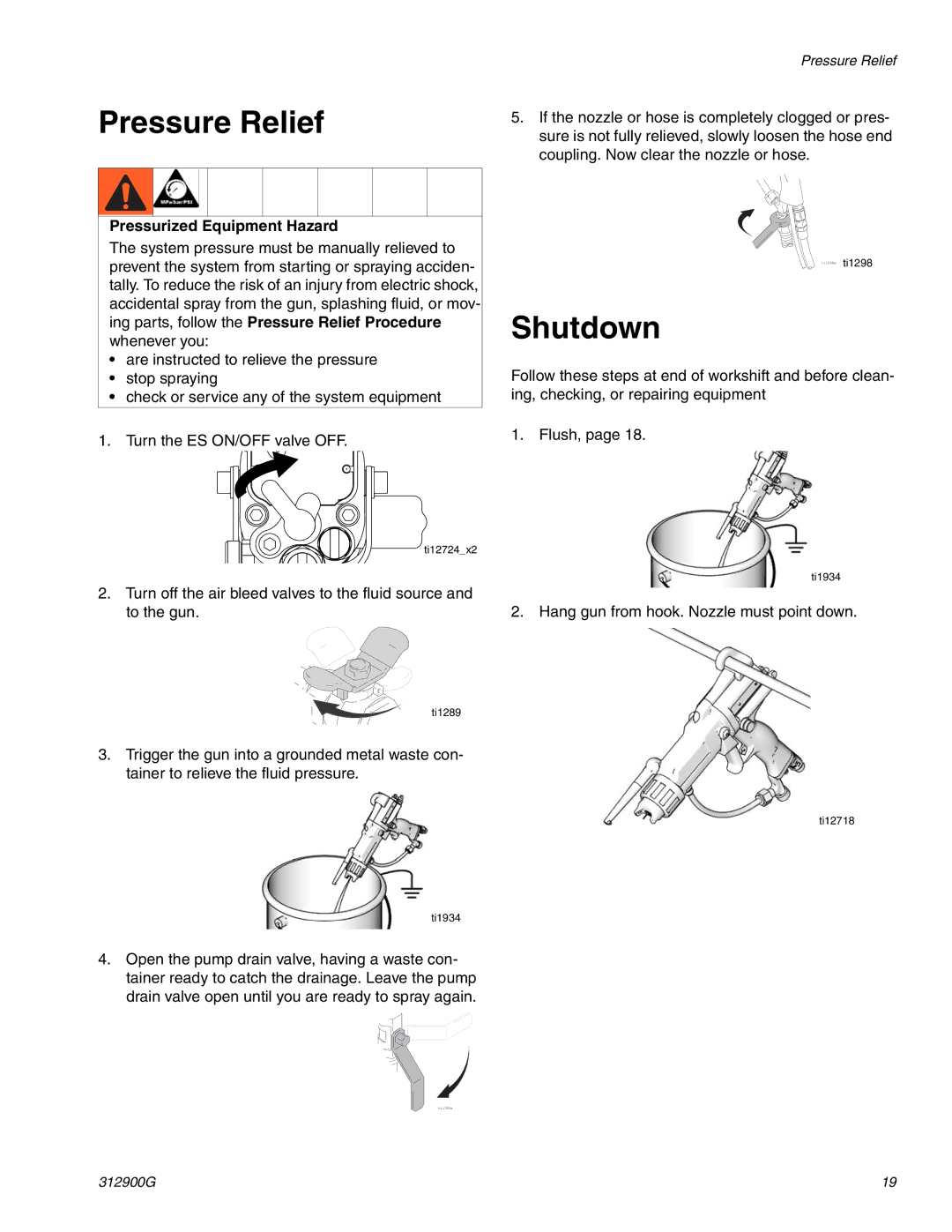

5.If the nozzle or hose is completely clogged or pres- sure is not fully relieved, slowly loosen the hose end coupling. Now clear the nozzle or hose.

Pressurized Equipment Hazard

The system pressure must be manually relieved to prevent the system from starting or spraying acciden- tally. To reduce the risk of an injury from electric shock, accidental spray from the gun, splashing fluid, or mov- ing parts, follow the Pressure Relief Procedure whenever you:

•are instructed to relieve the pressure

•stop spraying

•check or service any of the system equipment

1.Turn the ES ON/OFF valve OFF.

ti1298a ti1298

Shutdown

Follow these steps at end of workshift and before clean- ing, checking, or repairing equipment

1. Flush, page 18.

ti12724_x2

2.Turn off the air bleed valves to the fluid source and to the gun.

ti1289

3.Trigger the gun into a grounded metal waste con- tainer to relieve the fluid pressure.

ti1934

4.Open the pump drain valve, having a waste con- tainer ready to catch the drainage. Leave the pump drain valve open until you are ready to spray again.

ti1934

2. Hang gun from hook. Nozzle must point down.

ti12718

ti1290a

312900G | 19 |