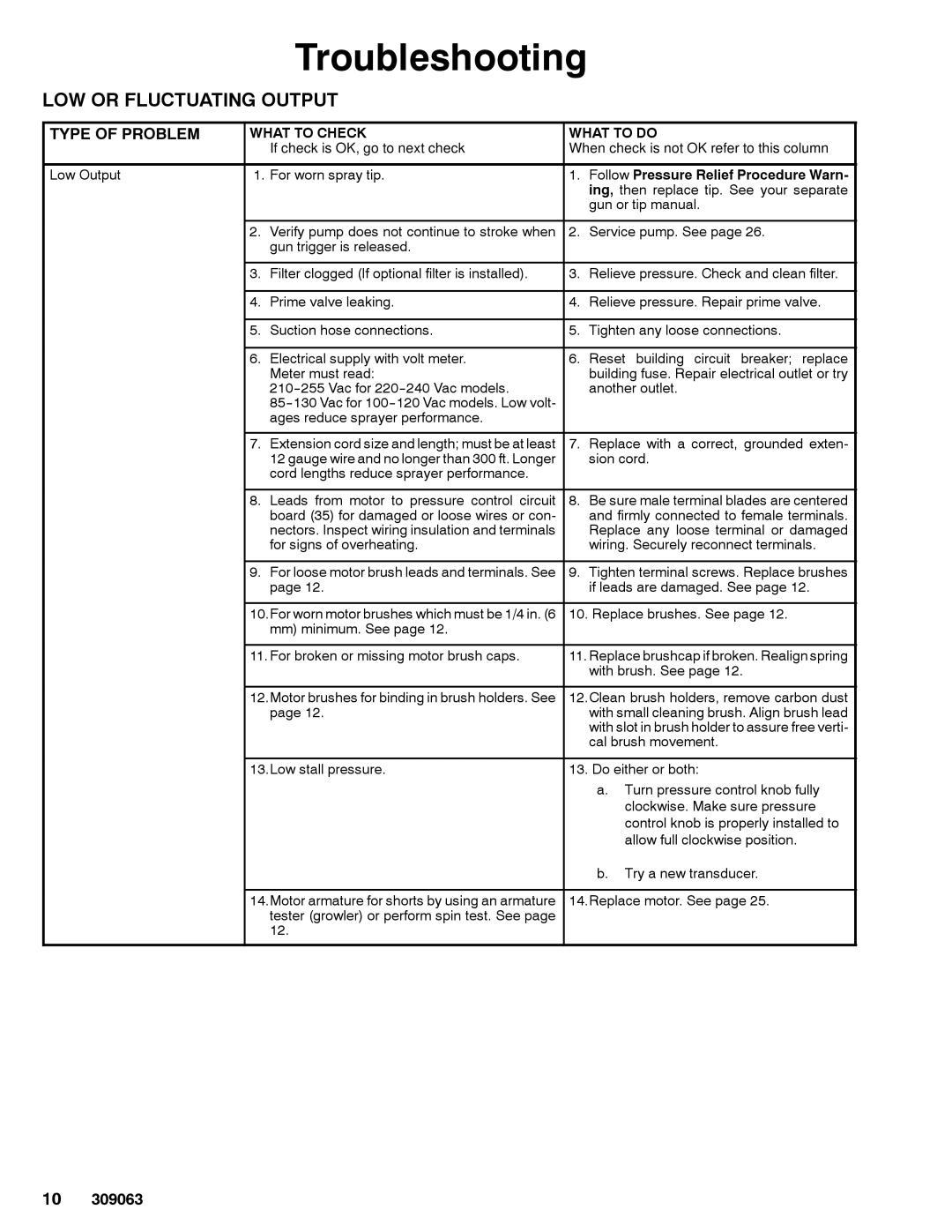

Troubleshooting

LOW OR FLUCTUATING OUTPUT

TYPE OF PROBLEM | WHAT TO CHECK | WHAT TO DO | ||

|

| If check is OK, go to next check | When check is not OK refer to this column | |

|

|

|

|

|

Low Output | 1. | For worn spray tip. | 1. | Follow Pressure Relief Procedure Warn- |

|

|

|

| ing, then replace tip. See your separate |

|

|

|

| gun or tip manual. |

|

|

|

|

|

| 2. | Verify pump does not continue to stroke when | 2. | Service pump. See page 26. |

|

| gun trigger is released. |

|

|

|

|

|

|

|

| 3. | Filter clogged (If optional filter is installed). | 3. | Relieve pressure. Check and clean filter. |

|

|

|

|

|

| 4. | Prime valve leaking. | 4. | Relieve pressure. Repair prime valve. |

|

|

|

|

|

| 5. | Suction hose connections. | 5. | Tighten any loose connections. |

|

|

|

|

|

| 6. | Electrical supply with volt meter. | 6. | Reset building circuit breaker; replace |

|

| Meter must read: |

| building fuse. Repair electrical outlet or try |

|

|

| another outlet. | |

|

|

|

| |

|

| ages reduce sprayer performance. |

|

|

|

|

|

|

|

| 7. | Extension cord size and length; must be at least | 7. | Replace with a correct, grounded exten- |

|

| 12 gauge wire and no longer than 300 ft. Longer |

| sion cord. |

|

| cord lengths reduce sprayer performance. |

|

|

|

|

|

|

|

| 8. | Leads from motor to pressure control circuit | 8. | Be sure male terminal blades are centered |

|

| board (35) for damaged or loose wires or con- |

| and firmly connected to female terminals. |

|

| nectors. Inspect wiring insulation and terminals |

| Replace any loose terminal or damaged |

|

| for signs of overheating. |

| wiring. Securely reconnect terminals. |

|

|

|

|

|

| 9. | For loose motor brush leads and terminals. See | 9. | Tighten terminal screws. Replace brushes |

|

| page 12. |

| if leads are damaged. See page 12. |

|

|

| ||

| 10.For worn motor brushes which must be 1/4 in. (6 | 10. Replace brushes. See page 12. | ||

|

| mm) minimum. See page 12. |

|

|

|

|

| ||

| 11. For broken or missing motor brush caps. | 11. Replace brushcap if broken. Realign spring | ||

|

|

|

| with brush. See page 12. |

|

|

| ||

| 12.Motor brushes for binding in brush holders. See | 12.Clean brush holders, remove carbon dust | ||

|

| page 12. |

| with small cleaning brush. Align brush lead |

|

|

|

| with slot in brush holder to assure free verti- |

|

|

|

| cal brush movement. |

|

|

| ||

| 13.Low stall pressure. | 13. Do either or both: | ||

|

|

|

| a. Turn pressure control knob fully |

|

|

|

| clockwise. Make sure pressure |

|

|

|

| control knob is properly installed to |

|

|

|

| allow full clockwise position. |

|

|

|

| b. Try a new transducer. |

|

|

| ||

| 14.Motor armature for shorts by using an armature | 14.Replace motor. See page 25. | ||

|

| tester (growler) or perform spin test. See page |

|

|

|

| 12. |

|

|

|

|

|

|

|

10309063