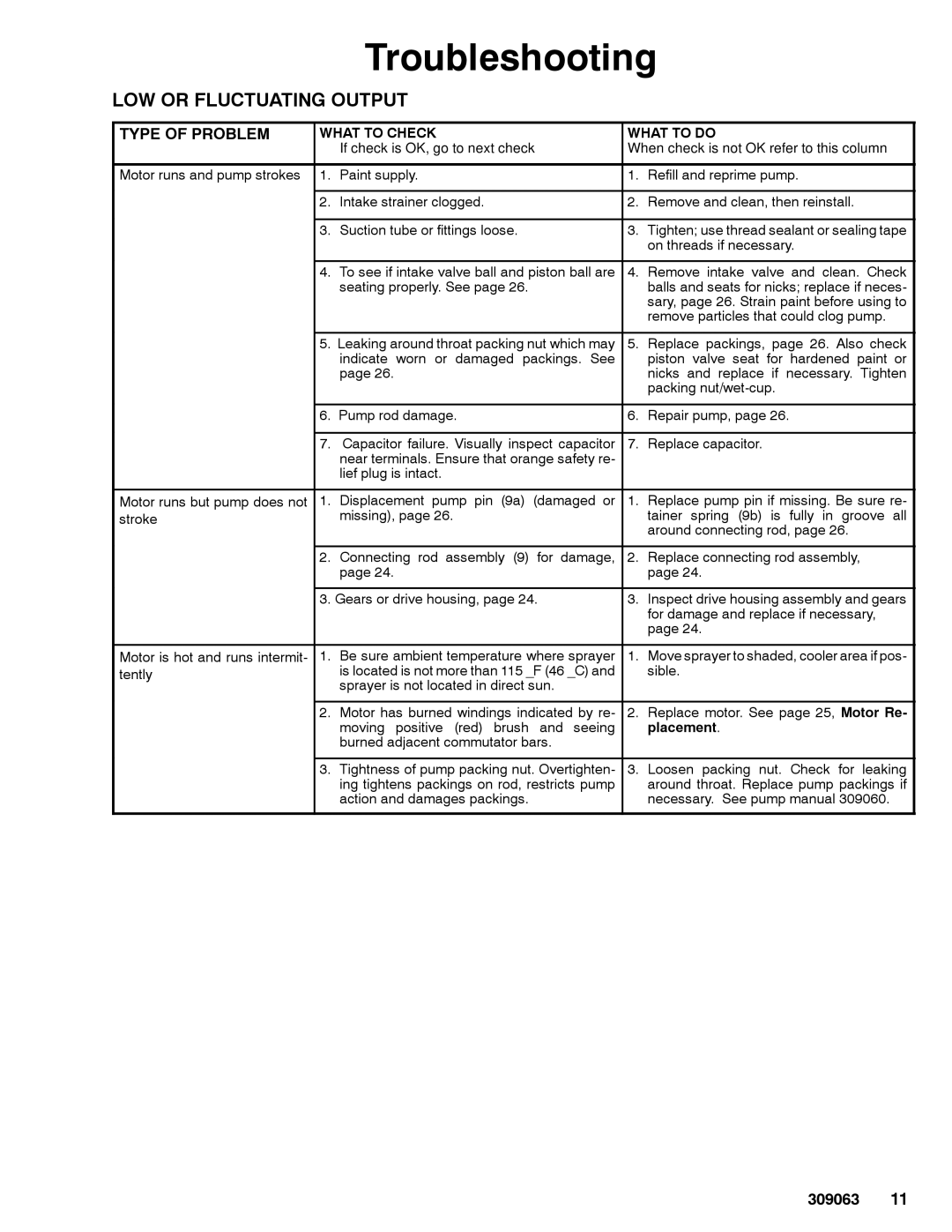

Troubleshooting

LOW OR FLUCTUATING OUTPUT

TYPE OF PROBLEM | WHAT TO CHECK | WHAT TO DO | ||

|

| If check is OK, go to next check | When check is not OK refer to this column | |

|

|

|

|

|

Motor runs and pump strokes | 1. | Paint supply. | 1. | Refill and reprime pump. |

|

|

|

|

|

| 2. | Intake strainer clogged. | 2. | Remove and clean, then reinstall. |

|

|

|

|

|

| 3. | Suction tube or fittings loose. | 3. | Tighten; use thread sealant or sealing tape |

|

|

|

| on threads if necessary. |

|

|

|

|

|

| 4. | To see if intake valve ball and piston ball are | 4. | Remove intake valve and clean. Check |

|

| seating properly. See page 26. |

| balls and seats for nicks; replace if neces- |

|

|

|

| sary, page 26. Strain paint before using to |

|

|

|

| remove particles that could clog pump. |

|

|

|

|

|

| 5. | Leaking around throat packing nut which may | 5. | Replace packings, page 26. Also check |

|

| indicate worn or damaged packings. See |

| piston valve seat for hardened paint or |

|

| page 26. |

| nicks and replace if necessary. Tighten |

|

|

|

| packing |

|

|

|

|

|

| 6. | Pump rod damage. | 6. | Repair pump, page 26. |

|

|

|

|

|

| 7. | Capacitor failure. Visually inspect capacitor | 7. | Replace capacitor. |

|

| near terminals. Ensure that orange safety re- |

|

|

|

| lief plug is intact. |

|

|

|

|

|

|

|

Motor runs but pump does not | 1. | Displacement pump pin (9a) (damaged or | 1. | Replace pump pin if missing. Be sure re- |

stroke |

| missing), page 26. |

| tainer spring (9b) is fully in groove all |

|

|

|

| around connecting rod, page 26. |

|

|

|

|

|

| 2. | Connecting rod assembly (9) for damage, | 2. | Replace connecting rod assembly, |

|

| page 24. |

| page 24. |

|

|

|

| |

| 3. Gears or drive housing, page 24. | 3. | Inspect drive housing assembly and gears | |

|

|

|

| for damage and replace if necessary, |

|

|

|

| page 24. |

|

|

|

|

|

Motor is hot and runs intermit- | 1. | Be sure ambient temperature where sprayer | 1. | Move sprayer to shaded, cooler area if pos- |

tently |

| is located is not more than 115 _F (46 _C) and |

| sible. |

|

| sprayer is not located in direct sun. |

|

|

|

|

|

|

|

| 2. | Motor has burned windings indicated by re- | 2. | Replace motor. See page 25, Motor Re- |

|

| moving positive (red) brush and seeing |

| placement. |

|

| burned adjacent commutator bars. |

|

|

|

|

|

|

|

| 3. | Tightness of pump packing nut. Overtighten- | 3. | Loosen packing nut. Check for leaking |

|

| ing tightens packings on rod, restricts pump |

| around throat. Replace pump packings if |

|

| action and damages packings. |

| necessary. See pump manual 309060. |

|

|

|

|

|