8.Install the trigger (10), pivot pin (17), wave washer (18), and screw (11). Torque the screw to

Service

12.Install the pattern adjustment valve assembly

17

![]() 18

18

![]() 11

11

10

ti4828a

FIG. 40

9.Apply a thin film of lubricant to the fluid nozzle seat and threads.

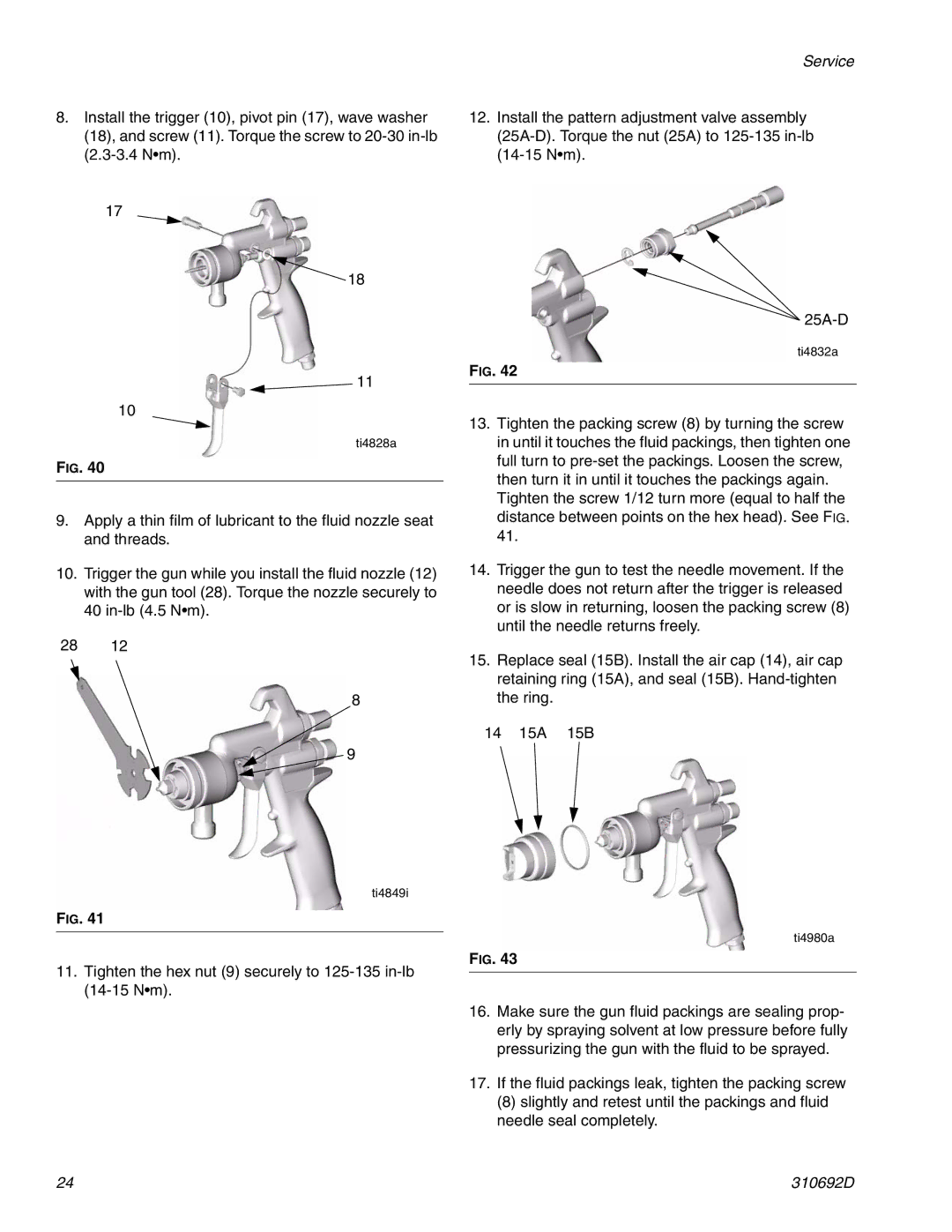

10.Trigger the gun while you install the fluid nozzle (12) with the gun tool (28). Torque the nozzle securely to 40

28 12

8

9

ti4849i

FIG. 41

11.Tighten the hex nut (9) securely to

ti4832a

FIG. 42

13.Tighten the packing screw (8) by turning the screw in until it touches the fluid packings, then tighten one full turn to

Tighten the screw 1/12 turn more (equal to half the distance between points on the hex head). See FIG. 41.

14.Trigger the gun to test the needle movement. If the needle does not return after the trigger is released or is slow in returning, loosen the packing screw (8) until the needle returns freely.

15.Replace seal (15B). Install the air cap (14), air cap retaining ring (15A), and seal (15B).

14 15A 15B

ti4980a

FIG. 43

16.Make sure the gun fluid packings are sealing prop- erly by spraying solvent at low pressure before fully pressurizing the gun with the fluid to be sprayed.

17.If the fluid packings leak, tighten the packing screw

(8) slightly and retest until the packings and fluid needle seal completely.

24 | 310692D |