Maintenance

Torque Instructions

NOTE: Fluid cover and manifold fasteners have a

If fluid cover or manifold fasteners have been loosened, it is important to torque them using the following procedure to improve sealing.

NOTE: Always completely torque fluid covers before torquing manifolds.

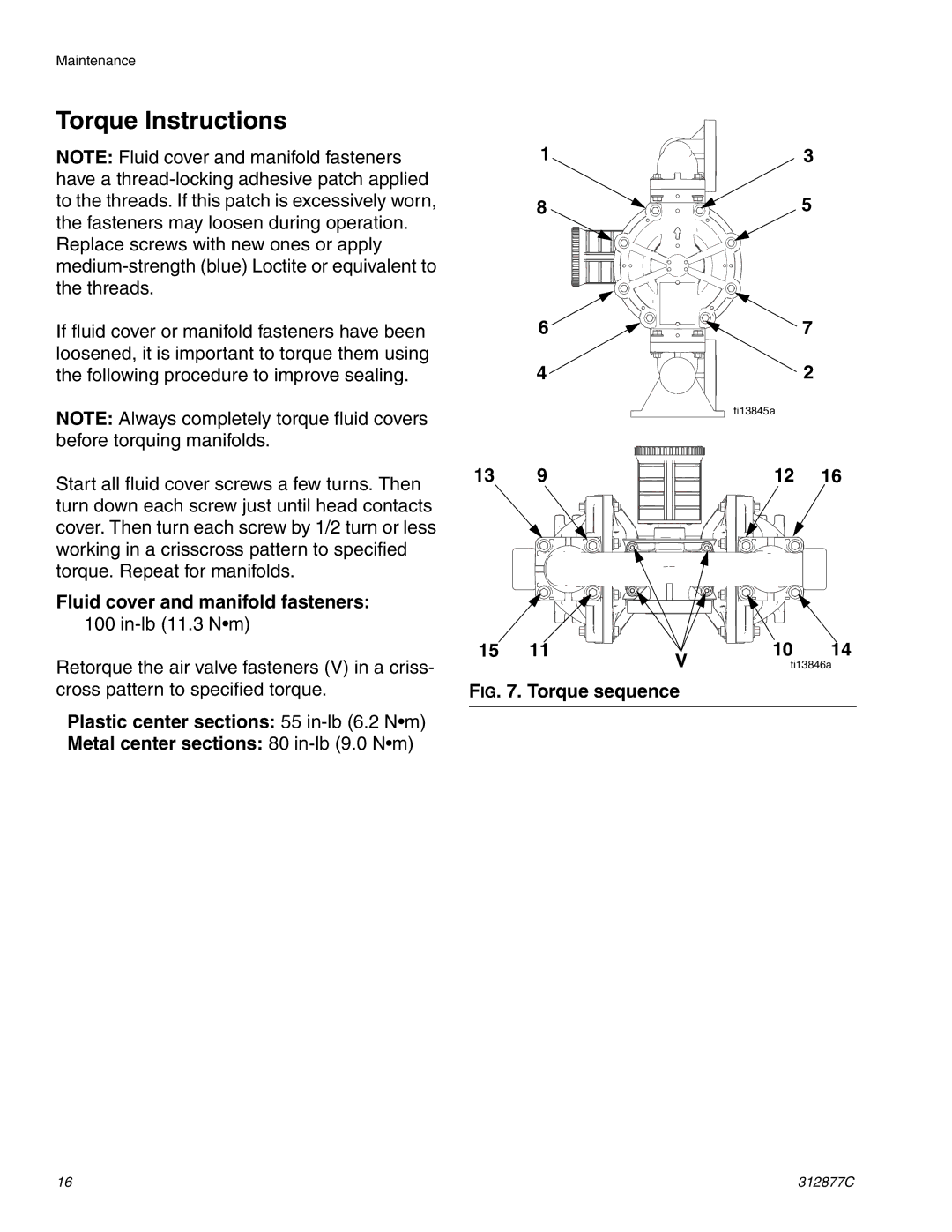

Start all fluid cover screws a few turns. Then turn down each screw just until head contacts cover. Then turn each screw by 1/2 turn or less working in a crisscross pattern to specified torque. Repeat for manifolds.

Fluid cover and manifold fasteners: 100

Retorque the air valve fasteners (V) in a criss- cross pattern to specified torque.

Plastic center sections: 55

Metal center sections: 80

1

8

6

4

13 9

15 11

V FIG. 7. Torque sequence

3

5

7

2

ti13845a

12 16

1014

ti13846a

16 | 312877C |