Pump Matrix

Pump Matrix

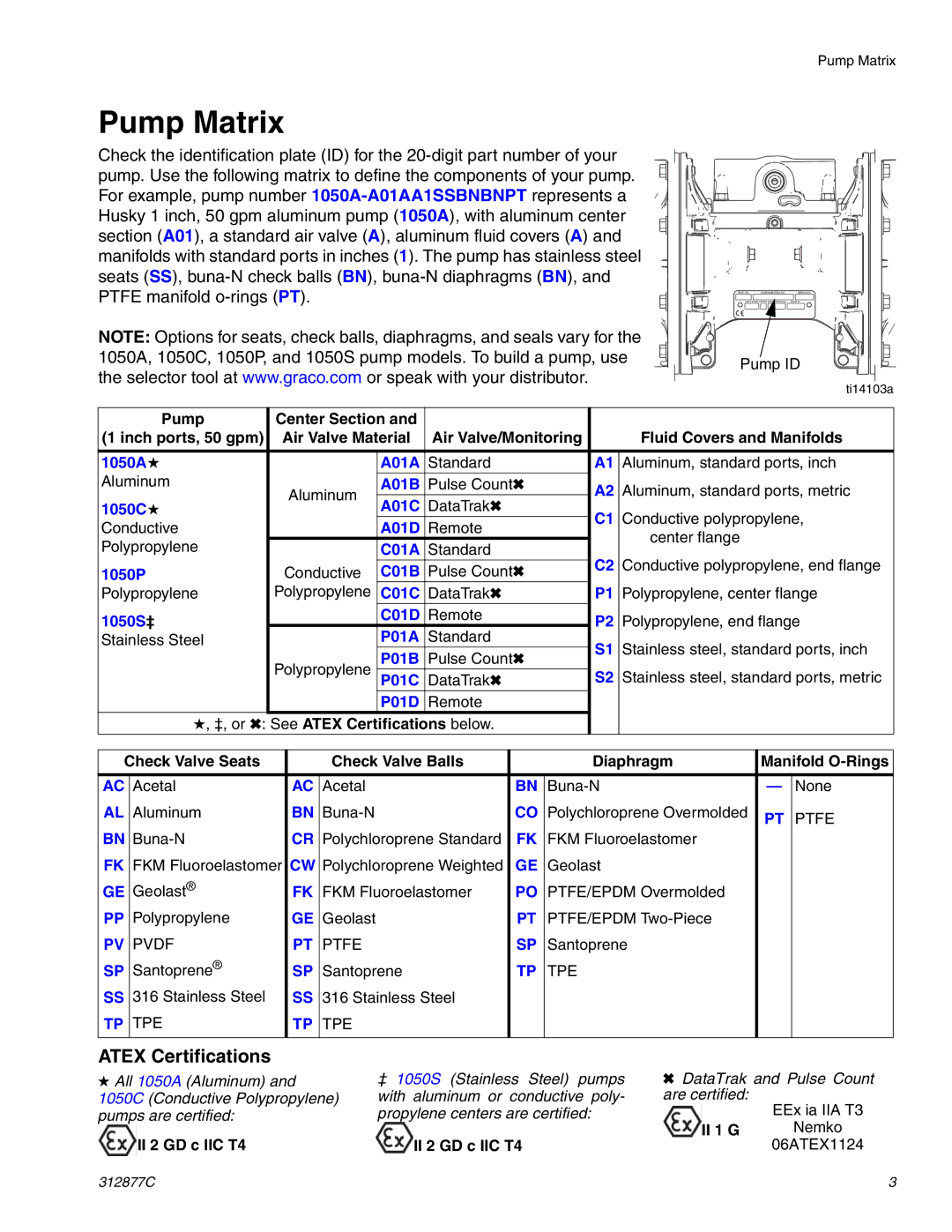

Check the identification plate (ID) for the

NOTE: Options for seats, check balls, diaphragms, and seals vary for the 1050A, 1050C, 1050P, and 1050S pump models. To build a pump, use the selector tool at www.graco.com or speak with your distributor.

| PART NO. |

| CONFIGURATION NO. |

|

| SERIAL NO. | |||||||

|

|

| DATE CODE SERIES MAX WPR | MADE IN | |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pump ID

ti14103a

| Pump | Center Section and |

|

|

|

|

|

|

| ||||

(1 inch ports, 50 gpm) | Air Valve Material | Air Valve/Monitoring |

| Fluid Covers and Manifolds | |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

| |

1050A★ |

|

|

| A01A | Standard |

|

| A1 | Aluminum, standard ports, inch | ||||

Aluminum |

| Aluminum | A01B | Pulse Count✖ | A2 | Aluminum, standard ports, metric | |||||||

1050C★ |

| A01C | DataTrak✖ |

|

| ||||||||

|

|

|

|

|

|

| |||||||

|

|

|

|

| C1 | Conductive polypropylene, | |||||||

Conductive |

|

|

| A01D | Remote |

|

| ||||||

|

|

|

|

|

| center flange |

|

| |||||

Polypropylene |

|

|

| C01A | Standard |

|

| C2 |

|

| |||

|

|

|

|

| Conductive polypropylene, end flange | ||||||||

1050P | Conductive | C01B | Pulse Count✖ | ||||||||||

|

|

|

| ||||||||||

Polypropylene | Polypropylene | C01C | DataTrak✖ |

|

| P1 | Polypropylene, center flange | ||||||

1050S‡ |

|

|

| C01D | Remote |

|

| P2 | Polypropylene, end flange | ||||

Stainless Steel |

|

|

| P01A | Standard |

|

| S1 | Stainless steel, standard ports, inch | ||||

|

| Polypropylene | P01B | Pulse Count✖ | |||||||||

|

|

|

|

|

| ||||||||

|

| P01C | DataTrak✖ |

|

| S2 | Stainless steel, standard ports, metric | ||||||

|

|

|

|

| P01D | Remote |

|

|

|

|

|

| |

| ★, ‡, or ✖: See ATEX Certifications below. |

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

| ||||

Check Valve Seats |

|

| Check Valve Balls |

|

| Diaphragm | Manifold | ||||||

|

|

|

|

|

|

|

|

|

|

| |||

AC | Acetal |

| AC | Acetal |

|

| BN |

| — | None | |||

AL | Aluminum |

| BN |

|

| CO | Polychloroprene Overmolded | PT | PTFE | ||||

|

|

|

|

|

|

|

|

|

|

| |||

BN |

| CR | Polychloroprene Standard | FK | FKM Fluoroelastomer |

|

| ||||||

FK | FKM Fluoroelastomer | CW | Polychloroprene Weighted | GE | Geolast |

|

|

| |||||

GE | Geolast® |

| FK | FKM Fluoroelastomer | PO | PTFE/EPDM Overmolded |

|

| |||||

PP | Polypropylene |

| GE | Geolast |

|

| PT | PTFE/EPDM |

|

| |||

PV | PVDF |

| PT | PTFE |

|

| SP | Santoprene |

|

| |||

SP | Santoprene® |

| SP | Santoprene | TP | TPE |

|

|

|

| |||

SS | 316 Stainless Steel |

| SS | 316 Stainless Steel |

|

|

|

|

|

| |||

TP | TPE |

| TP | TPE |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

| |

ATEX Certifications

★All 1050A (Aluminum) and 1050C (Conductive Polypropylene) pumps are certified:

II 2 GD c IIC T4

II 2 GD c IIC T4

‡1050S (Stainless Steel) pumps with aluminum or conductive poly- propylene centers are certified:

![]() II 2 GD c IIC T4

II 2 GD c IIC T4

✖DataTrak and Pulse Count are certified:

EEx ia IIA T3

II 1 G | Nemko |

| 06ATEX1124 |

312877C | 3 |