Installation

Fluid Inlet and Outlet Ports

NOTE: Remove and reverse the manifold(s) to change the orientation of inlet or outlet port(s). Follow Torque Instructions on page 16.

Aluminum (1050A)

The fluid inlet and outlet manifolds each have four 1 in. npt(f) or bspt threaded ports (FIG. 3, M, N). Close off the unused ports, using the supplied plugs.

Plastic (1050P, 1050C)

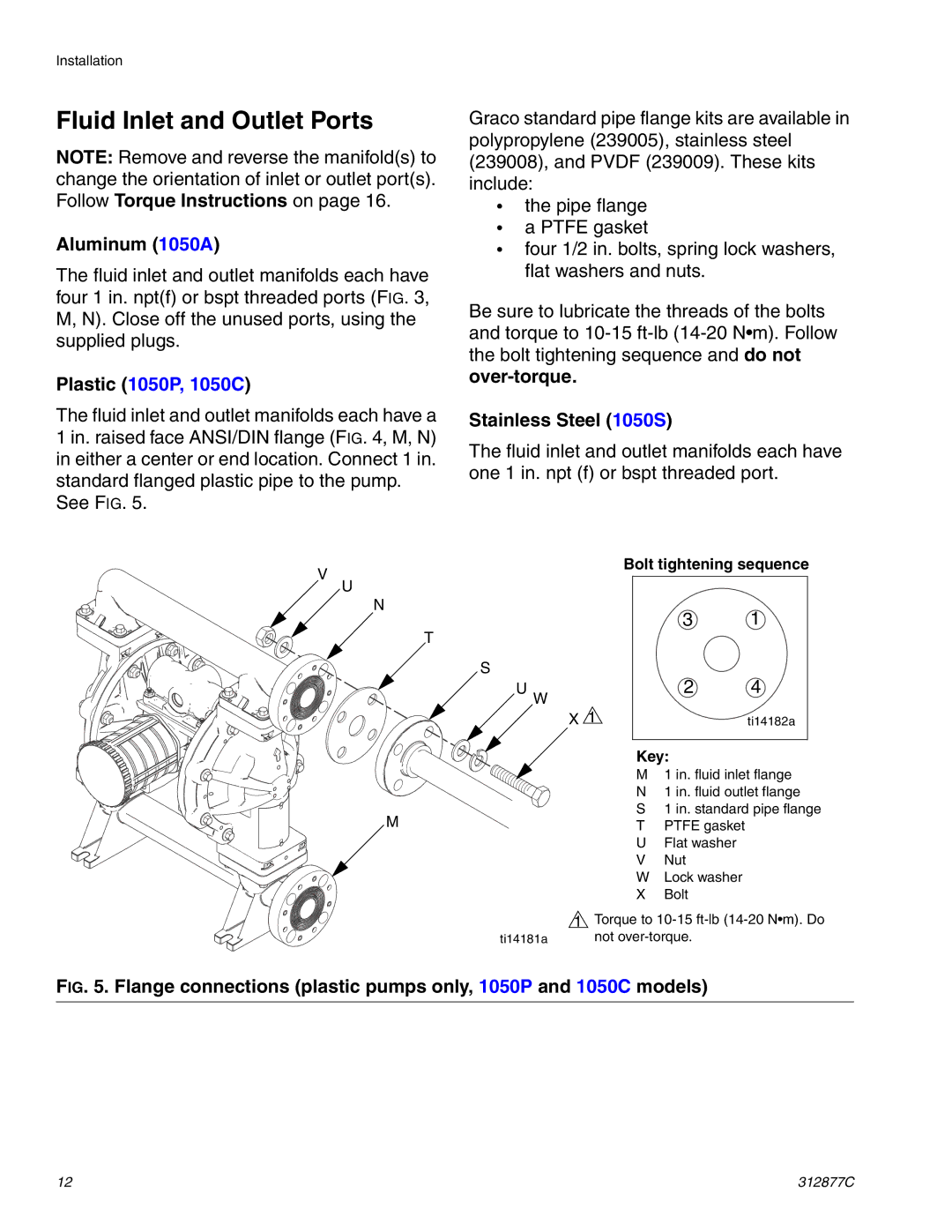

The fluid inlet and outlet manifolds each have a 1 in. raised face ANSI/DIN flange (FIG. 4, M, N) in either a center or end location. Connect 1 in. standard flanged plastic pipe to the pump.

See FIG. 5.

Graco standard pipe flange kits are available in polypropylene (239005), stainless steel (239008), and PVDF (239009). These kits include:

•the pipe flange

•a PTFE gasket

•four 1/2 in. bolts, spring lock washers, flat washers and nuts.

Be sure to lubricate the threads of the bolts and torque to

Stainless Steel (1050S)

The fluid inlet and outlet manifolds each have one 1 in. npt (f) or bspt threaded port.

V

U

N

T

S

U W

M

ti14181a

Bolt tightening sequence

3 1

2 4

X 1 | ti14182a |

Key:

M1 in. fluid inlet flange

N1 in. fluid outlet flange

S1 in. standard pipe flange

TPTFE gasket

UFlat washer

VNut

WLock washer

XBolt

1Torque to

FIG. 5. Flange connections (plastic pumps only, 1050P and 1050C models)

12 | 312877C |