Installation

|

|

|

|

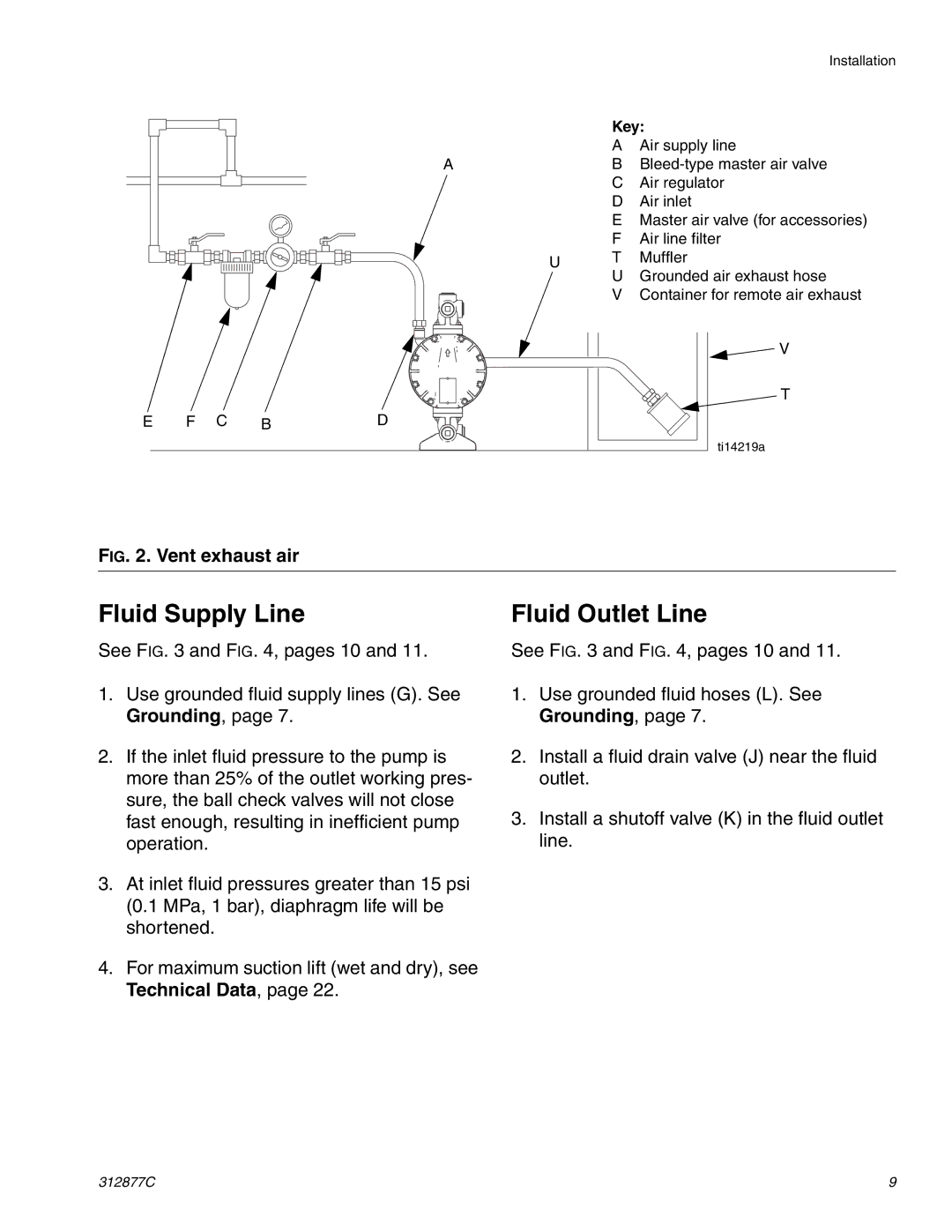

| Key: | |

|

|

|

|

| A | Air supply line |

|

|

| A |

| B | |

|

|

|

|

| C | Air regulator |

|

|

|

|

| D | Air inlet |

|

|

|

|

| E Master air valve (for accessories) | |

|

|

|

|

| F | Air line filter |

|

|

|

| U | T | Muffler |

|

|

|

| U | Grounded air exhaust hose | |

|

|

|

|

| ||

|

|

|

|

| V Container for remote air exhaust | |

|

|

|

|

|

| V |

|

|

|

|

|

| T |

E | F C | B | D |

|

|

|

|

|

|

|

|

| ti14219a |

FIG. 2. Vent exhaust air

Fluid Supply Line

See FIG. 3 and FIG. 4, pages 10 and 11.

1.Use grounded fluid supply lines (G). See Grounding, page 7.

2.If the inlet fluid pressure to the pump is more than 25% of the outlet working pres- sure, the ball check valves will not close fast enough, resulting in inefficient pump operation.

3.At inlet fluid pressures greater than 15 psi (0.1 MPa, 1 bar), diaphragm life will be shortened.

4.For maximum suction lift (wet and dry), see Technical Data, page 22.

Fluid Outlet Line

See FIG. 3 and FIG. 4, pages 10 and 11.

1.Use grounded fluid hoses (L). See Grounding, page 7.

2.Install a fluid drain valve (J) near the fluid outlet.

3.Install a shutoff valve (K) in the fluid outlet line.

312877C | 9 |