Configure Your System

1. Select a Base Model

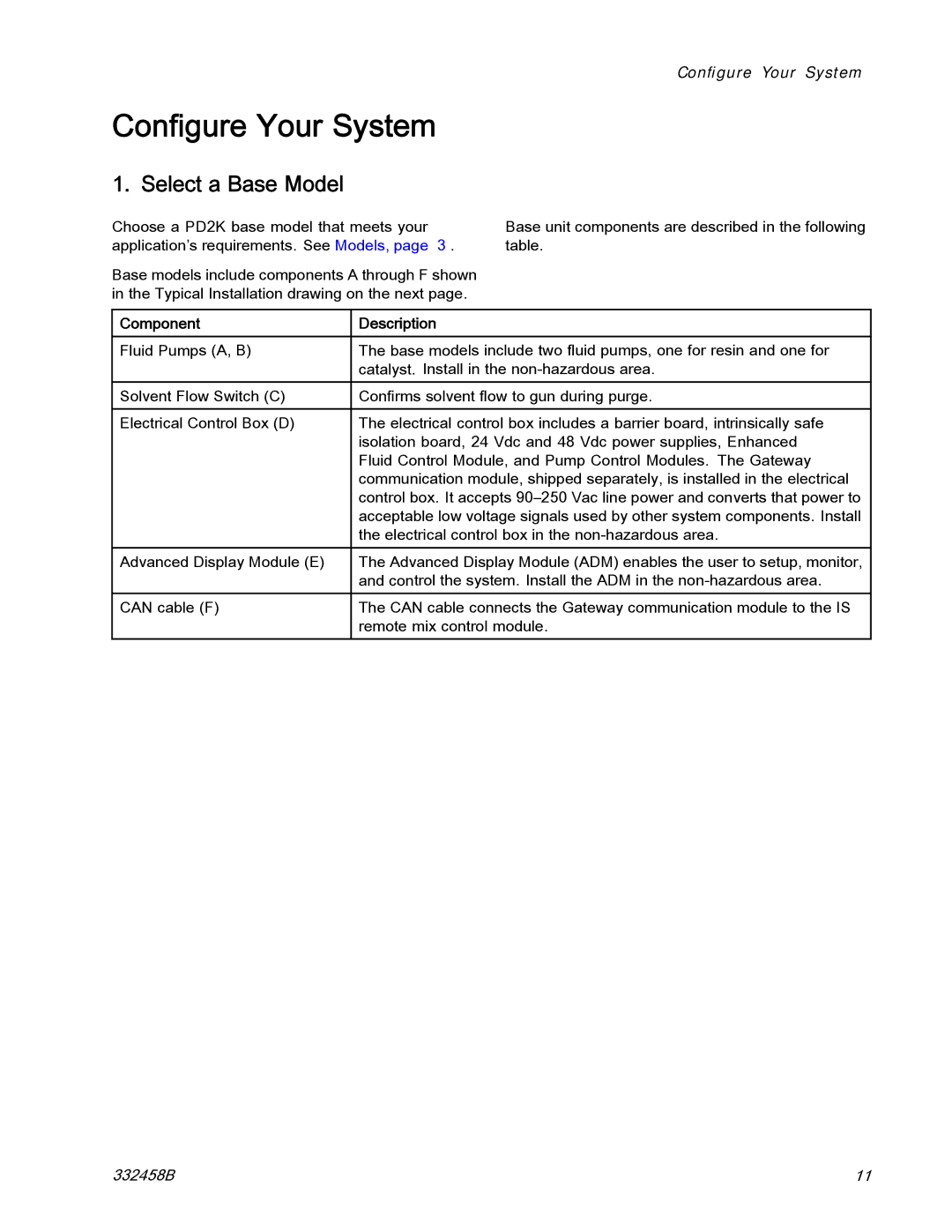

Choose a PD2K base model that meets your application’s requirements. See Models, page 3 .

Base models include components A through F shown in the Typical Installation drawing on the next page.

Configure Your System

Base unit components are described in the following table.

Component | Description |

|

|

Fluid Pumps (A, B) | The base models include two fluid pumps, one for resin and one for |

| catalyst. Install in the |

Solvent Flow Switch (C) | Confirms solvent flow to gun during purge. |

|

|

Electrical Control Box (D) | The electrical control box includes a barrier board, intrinsically safe |

| isolation board, 24 Vdc and 48 Vdc power supplies, Enhanced |

| Fluid Control Module, and Pump Control Modules. The Gateway |

| communication module, shipped separately, is installed in the electrical |

| control box. It accepts |

| acceptable low voltage signals used by other system components. Install |

| the electrical control box in the |

Advanced Display Module (E) | The Advanced Display Module (ADM) enables the user to setup, monitor, |

| and control the system. Install the ADM in the |

CAN cable (F) | The CAN cable connects the Gateway communication module to the IS |

| remote mix control module. |

332458B | 11 |