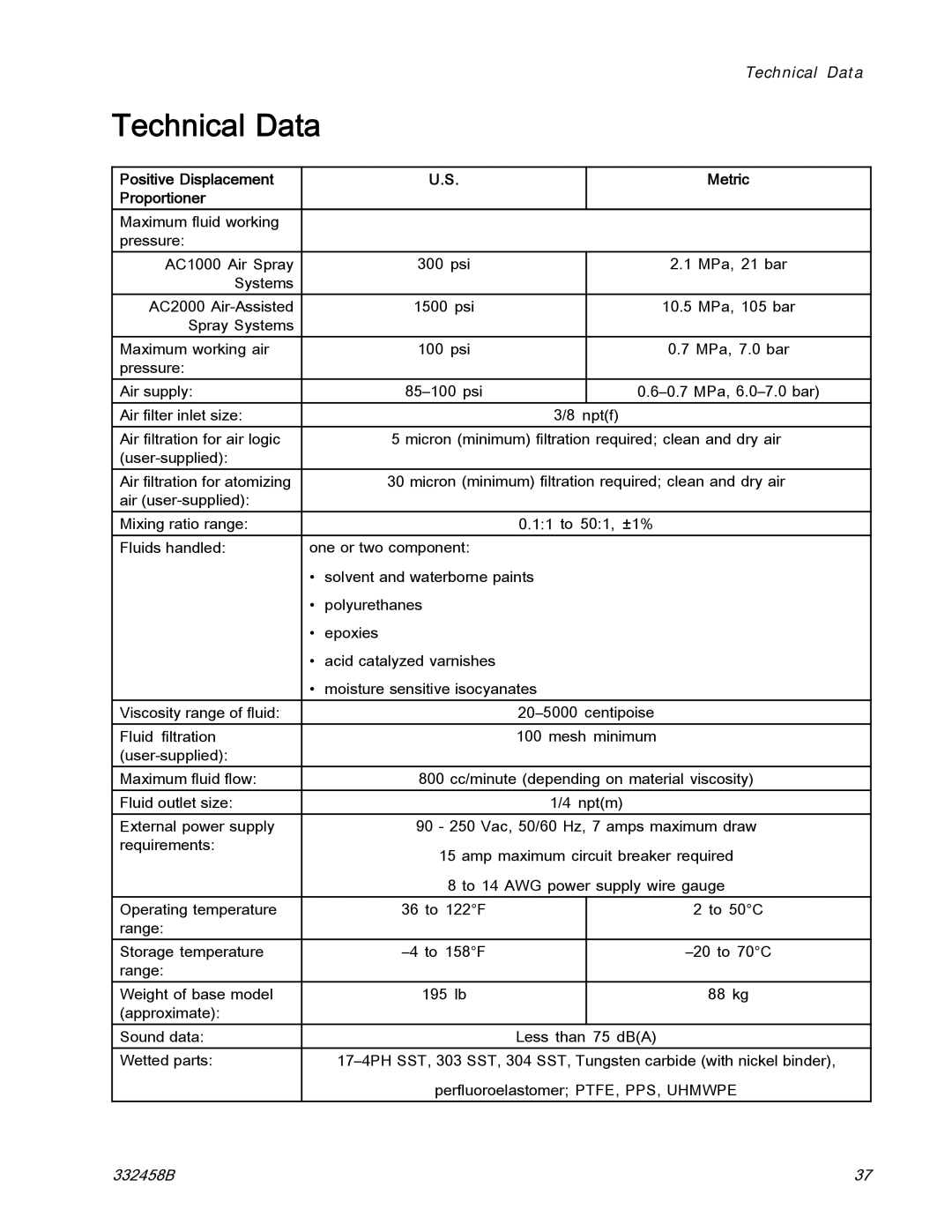

Technical Data

Technical Data

Positive Displacement |

| U.S. |

| Metric |

Proportioner |

|

|

|

|

Maximum fluid working |

|

|

|

|

pressure: |

|

|

|

|

AC1000 Air Spray |

| 300 psi |

| 2.1 MPa, 21 bar |

Systems |

|

|

|

|

AC2000 |

| 1500 psi |

| 10.5 MPa, 105 bar |

Spray Systems |

|

|

|

|

Maximum working air |

| 100 psi |

| 0.7 MPa, 7.0 bar |

pressure: |

|

|

|

|

Air supply: |

|

| ||

Air filter inlet size: |

| 3/8 | npt(f) | |

Air filtration for air logic |

| 5 micron (minimum) filtration required; clean and dry air | ||

|

|

|

| |

Air filtration for atomizing |

| 30 micron (minimum) filtration required; clean and dry air | ||

air |

|

|

|

|

Mixing ratio range: |

| 0.1:1 to 50:1, ±1% | ||

Fluids handled: | one or two component: |

|

| |

| • | solvent and waterborne paints |

|

|

| • | polyurethanes |

|

|

| • | epoxies |

|

|

| • | acid catalyzed varnishes |

|

|

| • | moisture sensitive isocyanates |

|

|

Viscosity range of fluid: |

| |||

Fluid filtration |

| 100 mesh minimum | ||

|

|

|

| |

Maximum fluid flow: |

| 800 cc/minute (depending on material viscosity) | ||

Fluid outlet size: |

| 1/4 npt(m) | ||

External power supply |

| 90 - 250 Vac, 50/60 Hz, 7 amps maximum draw | ||

requirements: |

| 15 amp maximum circuit breaker required | ||

|

| |||

|

| 8 to 14 AWG power supply wire gauge | ||

Operating temperature |

| 36 to 122°F |

| 2 to 50°C |

range: |

|

|

|

|

Storage temperature |

|

| ||

range: |

|

|

|

|

Weight of base model |

| 195 lb |

| 88 kg |

(approximate): |

|

|

|

|

Sound data: |

| Less than 75 dB(A) | ||

Wetted parts: |

| |||

|

| perfluoroelastomer; PTFE, PPS, UHMWPE | ||

332458B | 37 |