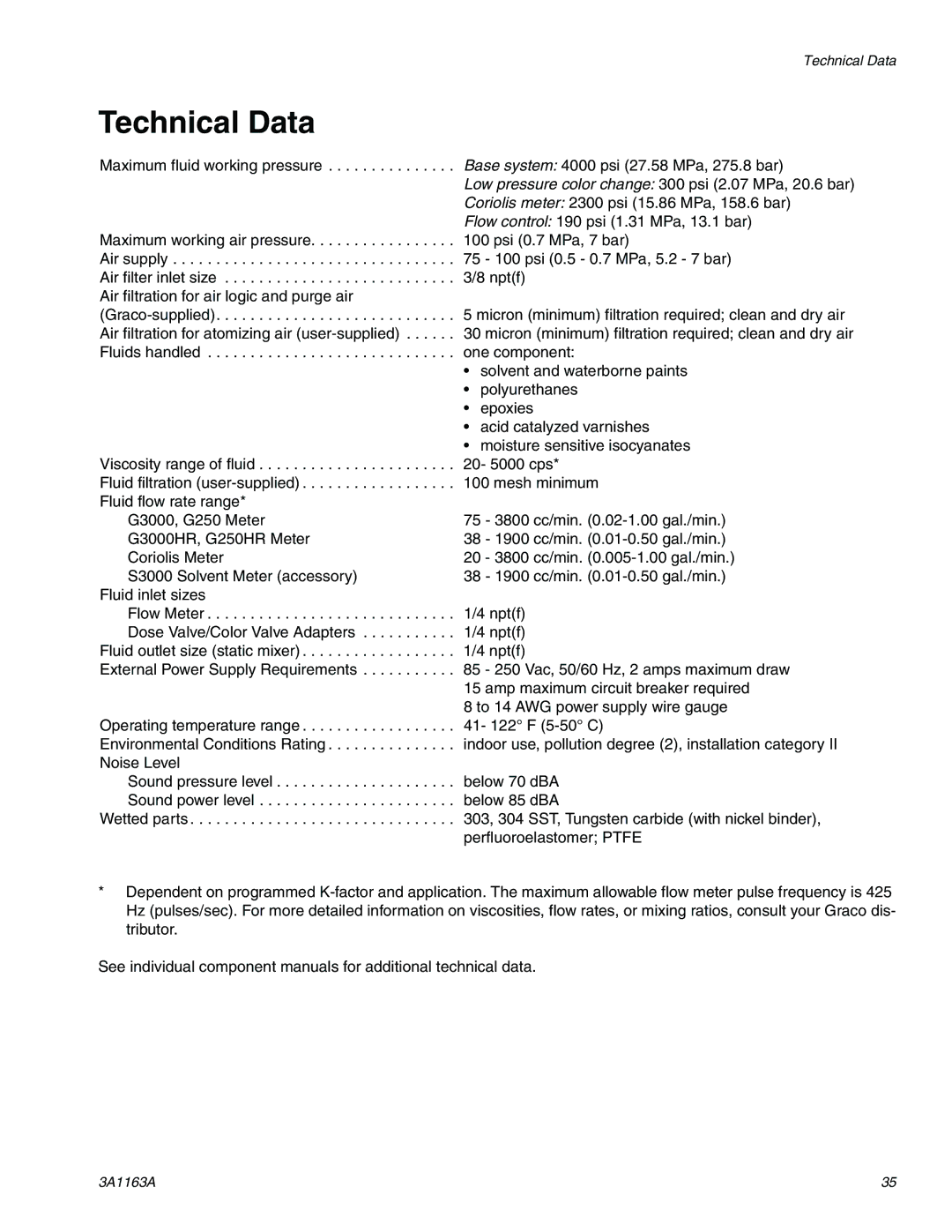

Technical Data

Technical Data

Maximum fluid working pressure . . . . . . . . . . . . . . .

Maximum working air pressure. . . . . . . . . . . . . . . . .

Air supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air filter inlet size . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air filtration for air logic and purge air

Air filtration for atomizing air

Fluids handled . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Viscosity range of fluid . . . . . . . . . . . . . . . . . . . . . . .

Fluid filtration

Fluid flow rate range* G3000, G250 Meter G3000HR, G250HR Meter Coriolis Meter

S3000 Solvent Meter (accessory) Fluid inlet sizes

Flow Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dose Valve/Color Valve Adapters . . . . . . . . . . .

Fluid outlet size (static mixer) . . . . . . . . . . . . . . . . . .

External Power Supply Requirements . . . . . . . . . . .

Operating temperature range . . . . . . . . . . . . . . . . . .

Environmental Conditions Rating . . . . . . . . . . . . . . .

Noise Level

Sound pressure level . . . . . . . . . . . . . . . . . . . . .

Sound power level . . . . . . . . . . . . . . . . . . . . . . .

Wetted parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Base system: 4000 psi (27.58 MPa, 275.8 bar)

Low pressure color change: 300 psi (2.07 MPa, 20.6 bar)

Coriolis meter: 2300 psi (15.86 MPa, 158.6 bar)

Flow control: 190 psi (1.31 MPa, 13.1 bar)

100 psi (0.7 MPa, 7 bar)

75 - 100 psi (0.5 - 0.7 MPa, 5.2 - 7 bar) 3/8 npt(f)

5 micron (minimum) filtration required; clean and dry air

30 micron (minimum) filtration required; clean and dry air one component:

•solvent and waterborne paints

•polyurethanes

•epoxies

•acid catalyzed varnishes

•moisture sensitive isocyanates

20- 5000 cps*

100 mesh minimum

75 - 3800 cc/min.

38 - 1900 cc/min.

20 - 3800 cc/min.

38 - 1900 cc/min.

1/4 npt(f) 1/4 npt(f) 1/4 npt(f)

85 - 250 Vac, 50/60 Hz, 2 amps maximum draw 15 amp maximum circuit breaker required

8 to 14 AWG power supply wire gauge

41- 122° F

indoor use, pollution degree (2), installation category II

below 70 dBA below 85 dBA

303, 304 SST, Tungsten carbide (with nickel binder), perfluoroelastomer; PTFE

*Dependent on programmed

See individual component manuals for additional technical data.

3A1163A | 35 |