Model 12006

Disassembly

1. | With trigger (20) depressed, remove collar (17) |

| securing nozzle (18) to gun. |

2. | Remove nozzle (18), holding adapter (10) firmly to |

| prevent it from turning. |

3. | Remove gasket (9). Clean and inspect for damage. |

4. | Remove adapter (10) from gun body. |

5. | Remove both screws (12) and lock washers (25) on |

| one side of trigger (20) and push both trigger pins |

| (13) out of body. |

6. | Loosen lock nut (15) at rear of gun. |

7. | Unthread spring retainer (16) and remove spring |

| (14). |

8. | Loosen and remove adjustment screw (6) on pack- |

| ing nut (3) and pull needle assembly from rear of |

| gun. Inspect for damage, replace if needed. |

Service

Reassembly

Clean all parts thoroughly before reassembling. Check them carefully for damage or wear. Replace parts as needed. For best results replace the original parts with new parts in repair kits.

Prior to assembly, lubricate all seals and

1. Replace

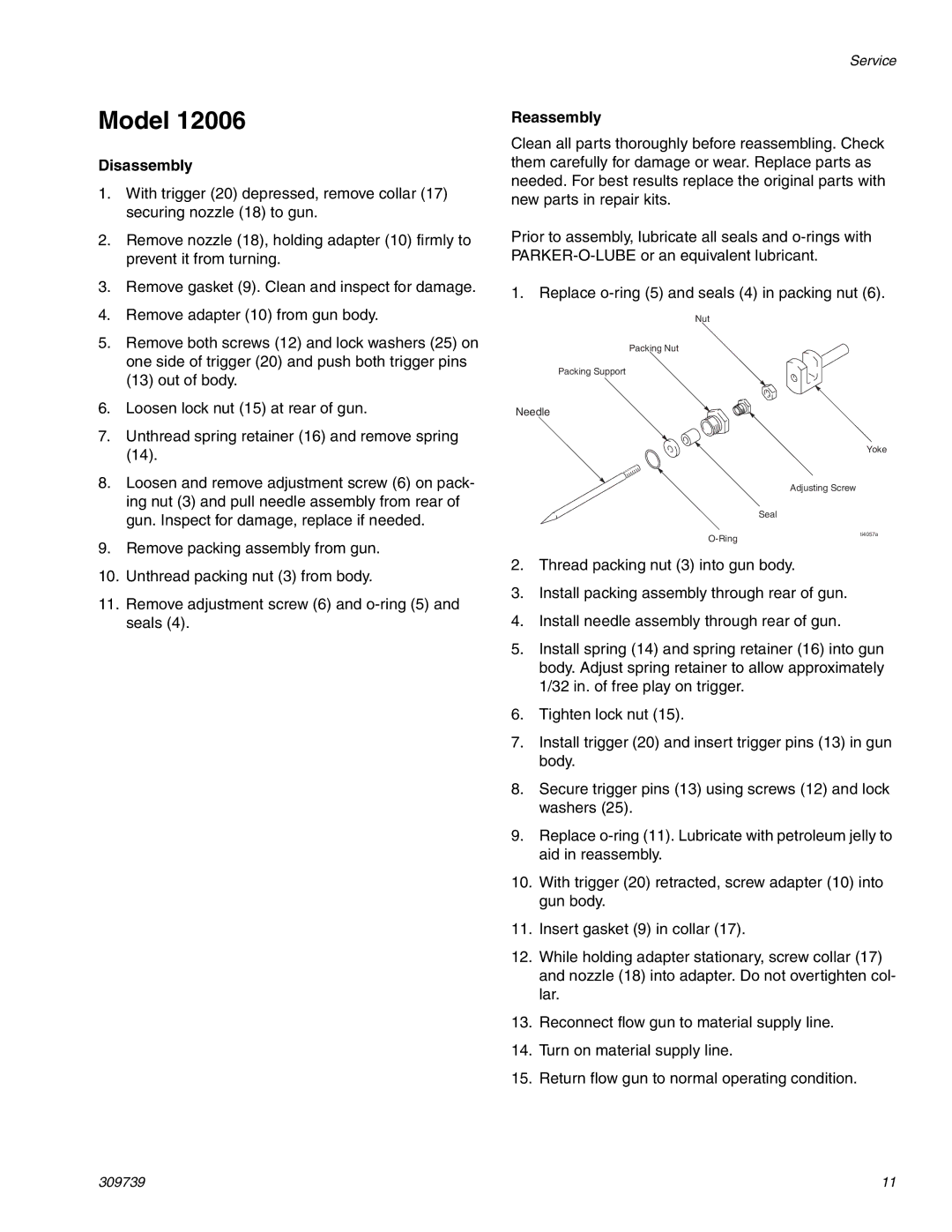

Nut

Packing Nut

Packing Support

Needle

Yoke

Adjusting Screw

Seal

ti4057a

9. | Remove packing assembly from gun. |

10. | Unthread packing nut (3) from body. |

11. | Remove adjustment screw (6) and |

| seals (4). |

2.Thread packing nut (3) into gun body.

3.Install packing assembly through rear of gun.

4.Install needle assembly through rear of gun.

5.Install spring (14) and spring retainer (16) into gun body. Adjust spring retainer to allow approximately 1/32 in. of free play on trigger.

6.Tighten lock nut (15).

7.Install trigger (20) and insert trigger pins (13) in gun body.

8.Secure trigger pins (13) using screws (12) and lock washers (25).

9.Replace

10.With trigger (20) retracted, screw adapter (10) into gun body.

11.Insert gasket (9) in collar (17).

12.While holding adapter stationary, screw collar (17) and nozzle (18) into adapter. Do not overtighten col- lar.

13.Reconnect flow gun to material supply line.

14.Turn on material supply line.

15.Return flow gun to normal operating condition.

309739 | 11 |