Installation

Installation

Inspect flow gun for shipping damage. If damage is found notify the carrier immediately.

If material hose will be suspended by a hanger or tool balancer, route hose through the suspension device before securing each end of material hose.

1.Connect flow gun to any standard Graco hose assembly.

2.Connect the opposite end of the heated hose assembly to any fluid supply system. See Model table, page 2 for maximum fluid working pressure for your gun model.

3.Tighten fluid connections.

4.Before operating gun, squeeze and release trigger a few cycles. Observe action of cartridge assembly.

Pressure Relief Procedure

To help prevent injuries, follow this procedure ![]()

![]() when you shut off the flow gun and before check- ing or adjusting any part of gun.

when you shut off the flow gun and before check- ing or adjusting any part of gun.

1.Shut off air to pump.

2.Close

3.Hold metal part of spray gun firmly to side of grounded metal pail. Trigger gun to relieve pressure.

ti3795a

4.Open drain valve and/or pump bleeder valve having a container ready to catch the drainage.

5.Leave drain valve open until you are ready to spray/dispense again.

If you suspect the tip/nozzle or hose is completely clogged or that pressure has not been fully relieved after following the above steps, VERY SLOWLY loosen the retaining nut or hose end coupling to relieve pressure gradually. Then loosen it completely. Clear tip/nozzle or hose.

Trigger Lock

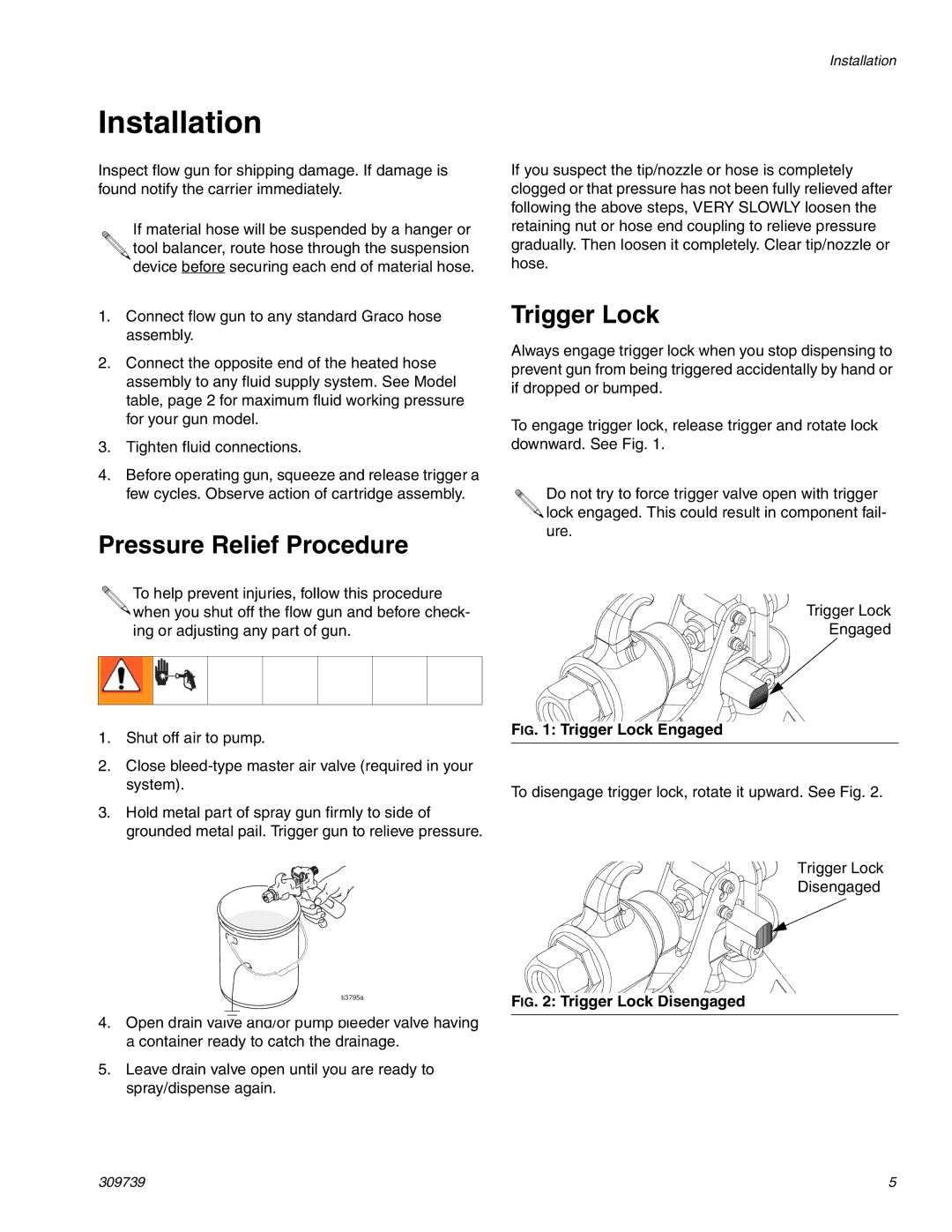

Always engage trigger lock when you stop dispensing to prevent gun from being triggered accidentally by hand or if dropped or bumped.

To engage trigger lock, release trigger and rotate lock downward. See Fig. 1.

Do not try to force trigger valve open with trigger ![]()

![]() lock engaged. This could result in component fail-

lock engaged. This could result in component fail-

ure.

Trigger Lock

Engaged

FIG. 1: Trigger Lock Engaged

To disengage trigger lock, rotate it upward. See Fig. 2.

Trigger Lock

Disengaged

FIG. 2: Trigger Lock Disengaged

309739 | 5 |