|

| Troubleshooting | |

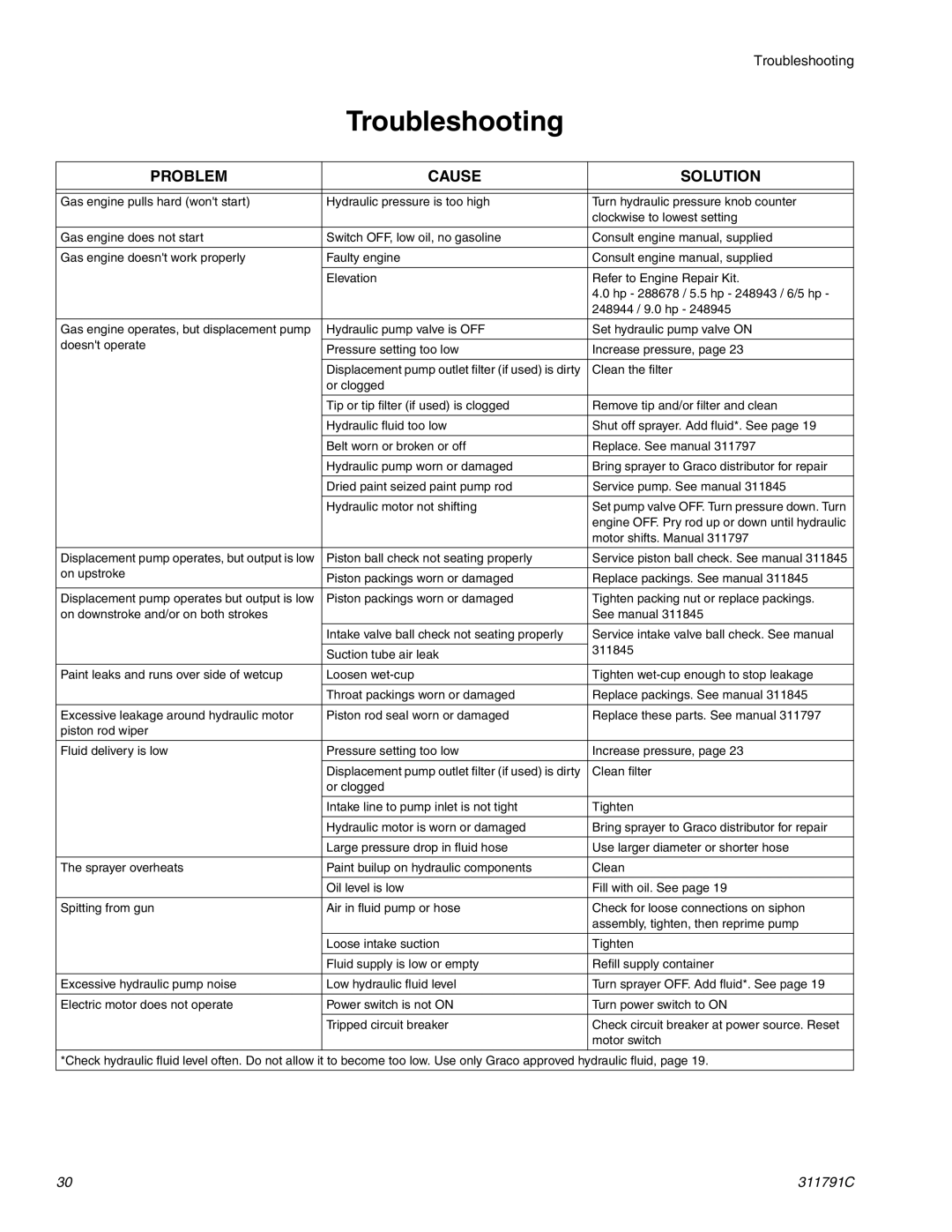

| Troubleshooting |

| |

|

|

| |

PROBLEM | CAUSE | SOLUTION | |

|

|

| |

|

|

| |

Gas engine pulls hard (won't start) | Hydraulic pressure is too high | Turn hydraulic pressure knob counter | |

|

| clockwise to lowest setting | |

|

|

| |

Gas engine does not start | Switch OFF, low oil, no gasoline | Consult engine manual, supplied | |

|

|

| |

Gas engine doesn't work properly | Faulty engine | Consult engine manual, supplied | |

|

|

| |

| Elevation | Refer to Engine Repair Kit. | |

|

| 4.0 hp - 288678 / 5.5 hp - 248943 / 6/5 hp - | |

|

| 248944 / 9.0 hp - 248945 | |

|

|

| |

Gas engine operates, but displacement pump | Hydraulic pump valve is OFF | Set hydraulic pump valve ON | |

doesn't operate |

|

| |

Pressure setting too low | Increase pressure, page 23 | ||

| |||

|

|

| |

| Displacement pump outlet filter (if used) is dirty | Clean the filter | |

| or clogged |

| |

|

|

| |

| Tip or tip filter (if used) is clogged | Remove tip and/or filter and clean | |

|

|

| |

| Hydraulic fluid too low | Shut off sprayer. Add fluid*. See page 19 | |

|

|

| |

| Belt worn or broken or off | Replace. See manual 311797 | |

|

|

| |

| Hydraulic pump worn or damaged | Bring sprayer to Graco distributor for repair | |

|

|

| |

| Dried paint seized paint pump rod | Service pump. See manual 311845 | |

|

|

| |

| Hydraulic motor not shifting | Set pump valve OFF. Turn pressure down. Turn | |

|

| engine OFF. Pry rod up or down until hydraulic | |

|

| motor shifts. Manual 311797 | |

|

|

| |

Displacement pump operates, but output is low | Piston ball check not seating properly | Service piston ball check. See manual 311845 | |

on upstroke |

|

| |

Piston packings worn or damaged | Replace packings. See manual 311845 | ||

| |||

|

|

| |

Displacement pump operates but output is low | Piston packings worn or damaged | Tighten packing nut or replace packings. | |

on downstroke and/or on both strokes |

| See manual 311845 | |

|

|

| |

| Intake valve ball check not seating properly | Service intake valve ball check. See manual | |

|

| 311845 | |

| Suction tube air leak | ||

|

| ||

|

|

| |

Paint leaks and runs over side of wetcup | Loosen | Tighten | |

|

|

| |

| Throat packings worn or damaged | Replace packings. See manual 311845 | |

|

|

| |

Excessive leakage around hydraulic motor | Piston rod seal worn or damaged | Replace these parts. See manual 311797 | |

piston rod wiper |

|

| |

|

|

| |

Fluid delivery is low | Pressure setting too low | Increase pressure, page 23 | |

|

|

| |

| Displacement pump outlet filter (if used) is dirty | Clean filter | |

| or clogged |

| |

|

|

| |

| Intake line to pump inlet is not tight | Tighten | |

|

|

| |

| Hydraulic motor is worn or damaged | Bring sprayer to Graco distributor for repair | |

|

|

| |

| Large pressure drop in fluid hose | Use larger diameter or shorter hose | |

|

|

| |

The sprayer overheats | Paint builup on hydraulic components | Clean | |

|

|

| |

| Oil level is low | Fill with oil. See page 19 | |

|

|

| |

Spitting from gun | Air in fluid pump or hose | Check for loose connections on siphon | |

|

| assembly, tighten, then reprime pump | |

|

|

| |

| Loose intake suction | Tighten | |

|

|

| |

| Fluid supply is low or empty | Refill supply container | |

|

|

| |

Excessive hydraulic pump noise | Low hydraulic fluid level | Turn sprayer OFF. Add fluid*. See page 19 | |

|

|

| |

Electric motor does not operate | Power switch is not ON | Turn power switch to ON | |

|

|

| |

| Tripped circuit breaker | Check circuit breaker at power source. Reset | |

|

| motor switch | |

|

|

| |

*Check hydraulic fluid level often. Do not allow it to become too low. Use only Graco approved hydraulic fluid, page 19. | |||

|

|

| |

30 | 311791C |