Operation / 操作

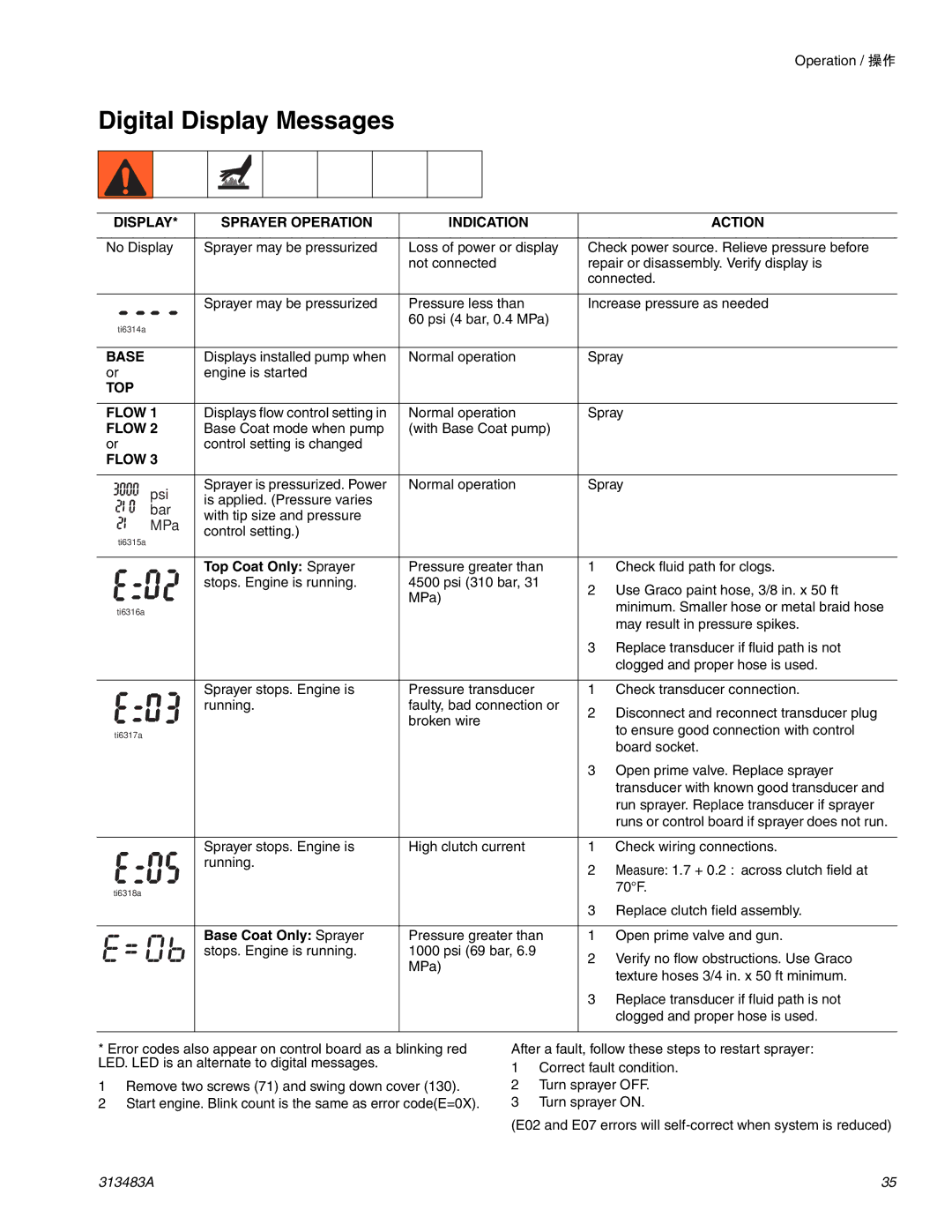

Digital Display Messages

DISPLAY* | SPRAYER OPERATION | INDICATION |

| ACTION |

|

|

|

| |

No Display | Sprayer may be pressurized | Loss of power or display | Check power source. Relieve pressure before | |

|

| not connected | repair or disassembly. Verify display is | |

|

|

| connected. | |

|

|

|

| |

| Sprayer may be pressurized | Pressure less than | Increase pressure as needed | |

ti6314a |

| 60 psi (4 bar, 0.4 MPa) |

|

|

|

|

|

| |

|

|

|

| |

BASE | Displays installed pump when | Normal operation | Spray | |

or | engine is started |

|

|

|

TOP |

|

|

|

|

|

|

|

| |

FLOW 1 | Displays flow control setting in | Normal operation | Spray | |

FLOW 2 | Base Coat mode when pump | (with Base Coat pump) |

|

|

or | control setting is changed |

|

|

|

FLOW 3 |

|

|

|

|

|

|

|

| |

psi | Sprayer is pressurized. Power | Normal operation | Spray | |

is applied. (Pressure varies |

|

|

| |

bar |

|

|

| |

with tip size and pressure |

|

|

| |

MPa |

|

|

| |

control setting.) |

|

|

| |

ti6315a |

|

|

| |

|

|

|

| |

|

|

|

|

|

| Top Coat Only: Sprayer | Pressure greater than | 1 | Check fluid path for clogs. |

| stops. Engine is running. | 4500 psi (310 bar, 31 | 2 | Use Graco paint hose, 3/8 in. x 50 ft |

|

| MPa) | ||

|

|

| minimum. Smaller hose or metal braid hose | |

ti6316a |

|

|

| |

|

|

|

| may result in pressure spikes. |

|

|

| 3 | Replace transducer if fluid path is not |

|

|

|

| clogged and proper hose is used. |

|

|

|

|

|

| Sprayer stops. Engine is | Pressure transducer | 1 | Check transducer connection. |

| running. | faulty, bad connection or | 2 | Disconnect and reconnect transducer plug |

|

| broken wire | ||

|

|

| to ensure good connection with control | |

ti6317a |

|

|

| |

|

|

|

| board socket. |

|

|

| 3 | Open prime valve. Replace sprayer |

|

|

|

| transducer with known good transducer and |

|

|

|

| run sprayer. Replace transducer if sprayer |

|

|

|

| runs or control board if sprayer does not run. |

|

|

|

|

|

| Sprayer stops. Engine is | High clutch current | 1 | Check wiring connections. |

| running. |

| 2 | Measure: 1.7 + 0.2Ω across clutch field at |

|

|

| ||

ti6318a |

|

|

| 70°F. |

|

|

|

| |

|

|

| 3 | Replace clutch field assembly. |

|

|

|

|

|

| Base Coat Only: Sprayer | Pressure greater than | 1 | Open prime valve and gun. |

| stops. Engine is running. | 1000 psi (69 bar, 6.9 | 2 | Verify no flow obstructions. Use Graco |

|

| MPa) | ||

|

|

| texture hoses 3/4 in. x 50 ft minimum. | |

|

|

|

| |

|

|

| 3 | Replace transducer if fluid path is not |

|

|

|

| clogged and proper hose is used. |

|

|

|

|

|

*Error codes also appear on control board as a blinking red LED. LED is an alternate to digital messages.

1Remove two screws (71) and swing down cover (130).

2Start engine. Blink count is the same as error code(E=0X).

After a fault, follow these steps to restart sprayer:

1Correct fault condition.

2Turn sprayer OFF.

3Turn sprayer ON.

(E02 and E07 errors will

313483A | 35 |