Troubleshooting

Gun Operation Troubleshooting (continued)

Excessive spray fog | The air pressure is too high. | Reduce the air cap air pressure by | |

|

|

| closing the atomizing air valve more |

|

|

| or decreasing the gun air inlet pres- |

|

|

| sure; use the least air pressure |

|

|

| needed for good results. Do not re- |

|

|

| duce below minimum pressure need- |

|

|

| ed for full voltage. See page 18. |

| The fluid is thinned too much. | Properly thin the fluid. | |

No fluid sprays from the gun | The fluid supply is low. |

| Check the fluid supply; add fluid if |

|

|

| necessary. |

| The fluid nozzle is dirty or clogged. | Clean the fluid nozzle; see page 21. | |

| The fluid nozzle is damaged. | Replace the fluid nozzle; see page | |

|

|

| 30. |

The equipment is covered with | The exhaust air flow is insufficient or | Check for the proper CFM; check the | |

fluid | not directed properly. |

| baffles and direction of the air flow. |

| The distance between the gun and | Adjust the spraying distance to 8 to | |

| workpiece is incorrect. |

| 12 inches (203 to 305 mm). |

Dirty air cap | The electrode is bent. |

| Straighten the electrode. |

| The nozzle orifice is damaged. | Replace the fluid nozzle; see page | |

|

|

| 30. |

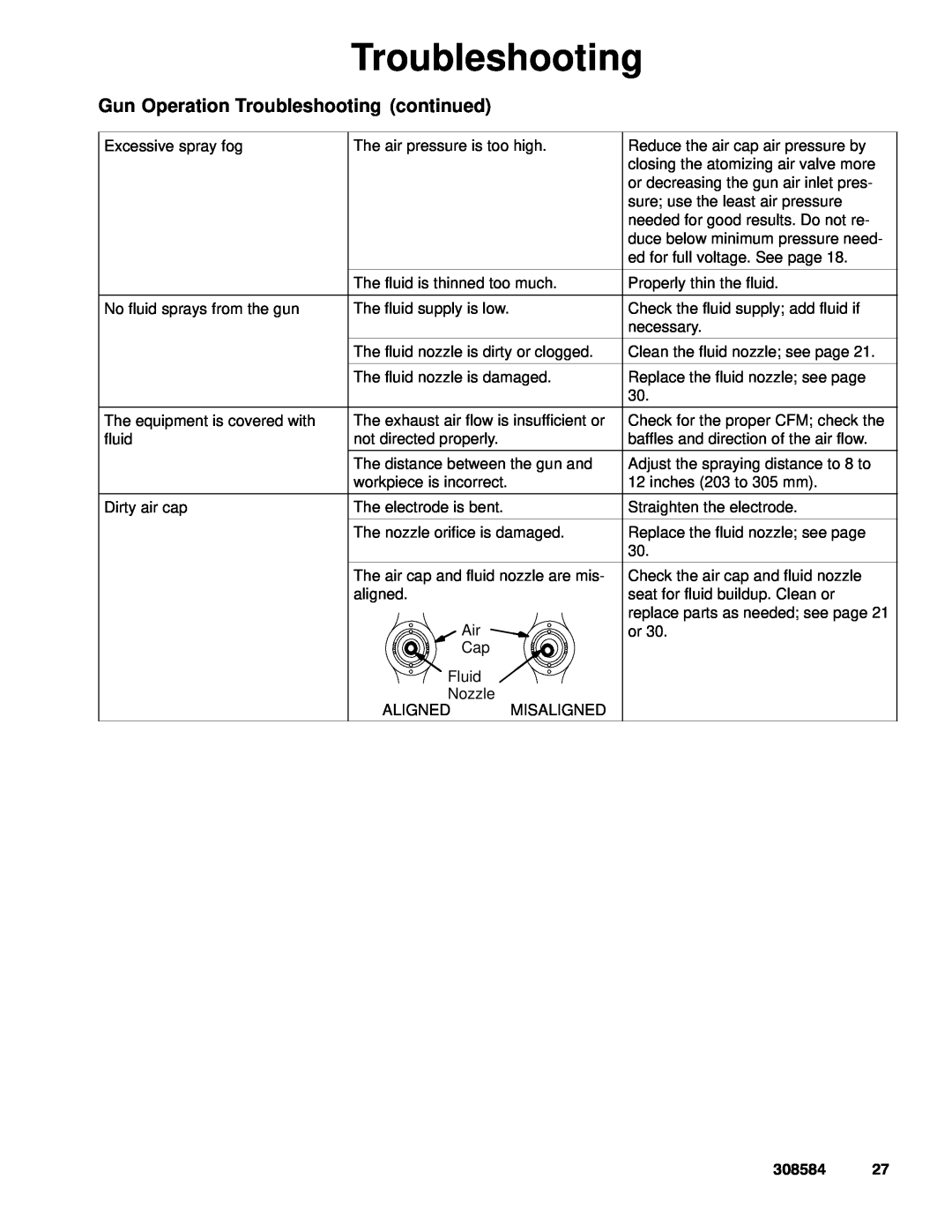

| The air cap and fluid nozzle are mis- | Check the air cap and fluid nozzle | |

| aligned. |

| seat for fluid buildup. Clean or |

| Air |

| replace parts as needed; see page 21 |

|

| or 30. | |

| Cap |

|

|

| Fluid |

|

|

| Nozzle |

|

|

| ALIGNED | MISALIGNED |

|

308584 27