800-232, 802-776 specifications

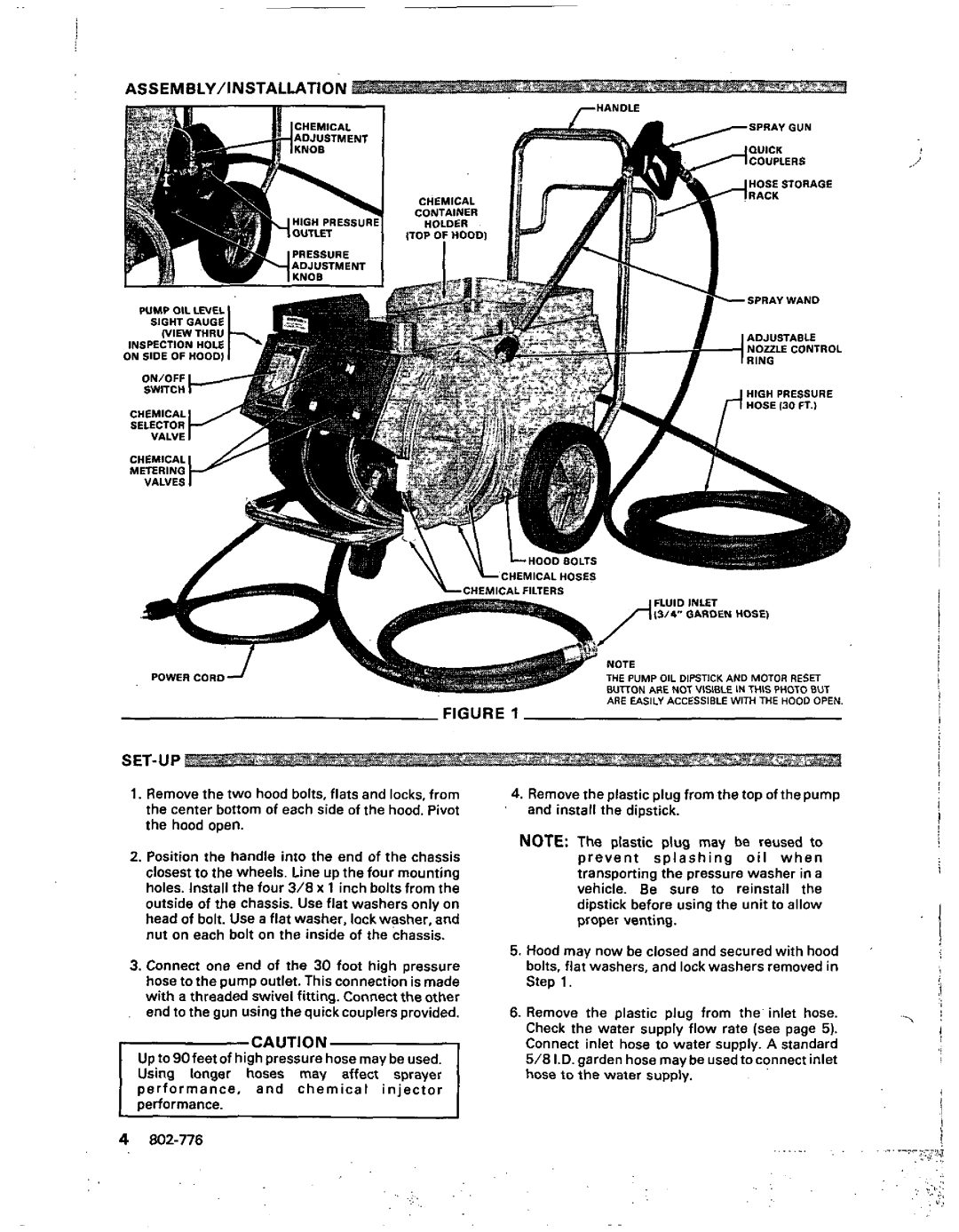

Graco Inc. is a well-known manufacturer in the fluid handling industry, providing a diverse range of products designed to facilitate the efficient and safe transfer of fluids. Among its notable offerings are the Graco Inc. models 802-776 and 800-232, which cater to different applications requiring precision and reliability in fluid handling.The Graco 802-776 is particularly recognized for its robust design and outstanding performance in high-pressure environments. This model is typically utilized in applications such as air-powered spray guns and paint distribution systems, making it ideal for professionals in the automotive, manufacturing, and construction industries. One of the main features of the 802-776 is its high flow rate, allowing users to complete tasks more efficiently. Additionally, the unit is equipped with a heavy-duty construction that minimizes wear and tear, thus extending its operational lifespan.

On the other hand, the Graco 800-232 is engineered for versatility, providing solutions for a variety of fluid types, including paints, coatings, and adhesives. This unit is highly adaptable, making it suitable for both industrial and commercial uses. A standout feature of the 800-232 is its compact design, which facilitates easy transport and maneuverability in tight spaces. Users appreciate its user-friendly interface, which simplifies operation, reducing the learning curve for new staff or operators.

Both models are equipped with advanced technologies that enhance functionality and safety. For instance, they include pressure control features that provide stability in fluid delivery, ensuring that users can achieve consistent results regardless of application conditions. Furthermore, Graco products are designed with durable materials, ensuring longevity and reliability over time, which is essential in demanding work environments.

Safety is also a critical aspect of the design for both models. They incorporate various safety features to minimize risks during operation, including automatic shut-off mechanisms and pressure relief valves. These technologies not only protect the equipment but also ensure the safety of the personnel operating them.

In summary, Graco Inc. models 802-776 and 800-232 are exemplary products that showcase the company's commitment to delivering high-quality fluid handling solutions. With their unique features, advanced technologies, and user-centric designs, these units are well-suited for a broad range of applications, addressing the demands of modern industries effectively.