SECTION 7: SERVICE

About Service

This section is provided for your

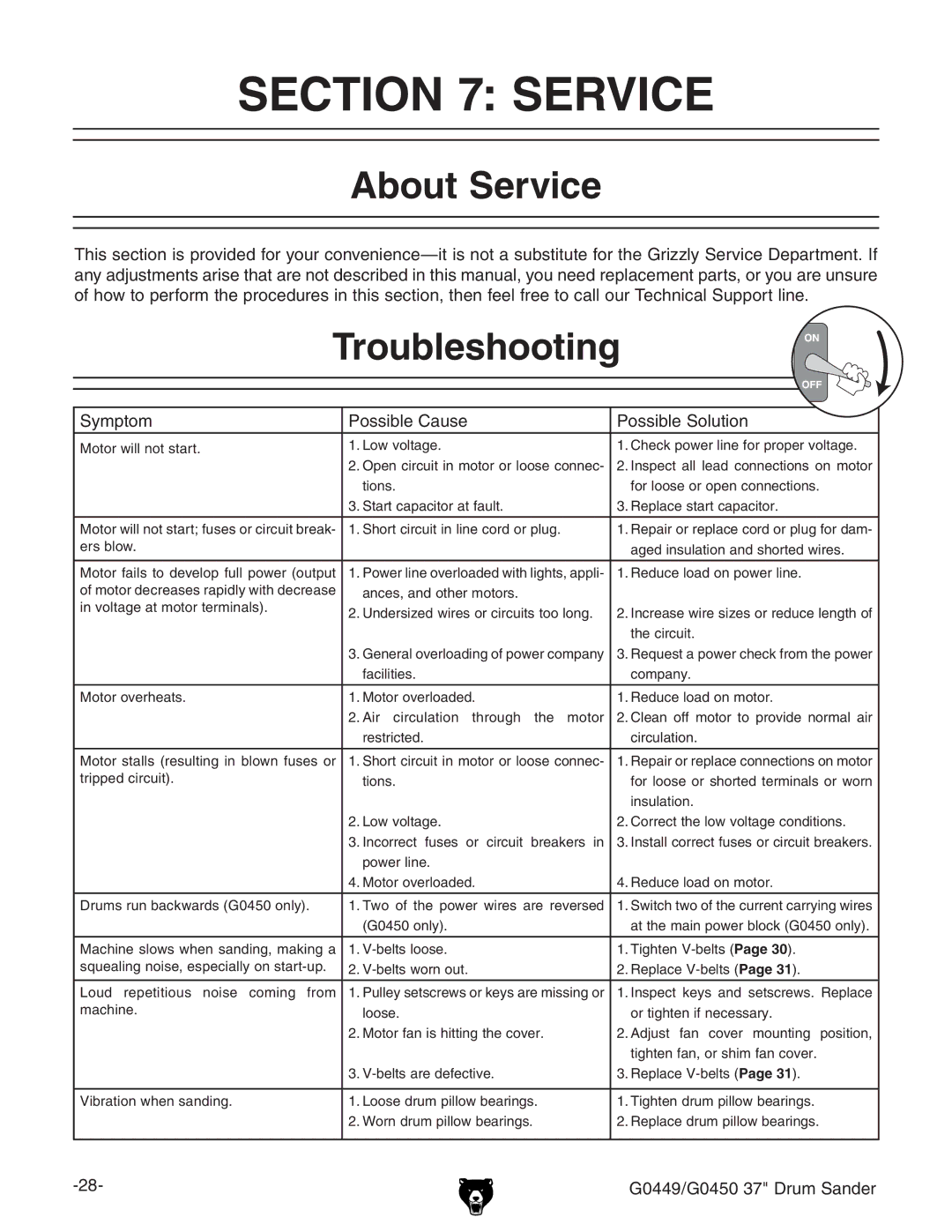

Troubleshooting

Symptom | Possible Cause |

| Possible Solution | |

Motor will not start. | 1. Low voltage. |

|

| 1. Check power line for proper voltage. |

| 2. Open circuit in motor or loose connec- | 2. Inspect all lead connections on motor | ||

| tions. |

|

| for loose or open connections. |

| 3. Start capacitor at fault. |

| 3. Replace start capacitor. | |

|

|

| ||

Motor will not start; fuses or circuit break- | 1. Short circuit in line cord or plug. | 1. Repair or replace cord or plug for dam- | ||

ers blow. |

|

|

| aged insulation and shorted wires. |

|

|

| ||

Motor fails to develop full power (output | 1. Power line overloaded with lights, appli- | 1. Reduce load on power line. | ||

of motor decreases rapidly with decrease | ances, and other motors. |

|

| |

in voltage at motor terminals). | 2. Undersized wires or circuits too long. | 2. Increase wire sizes or reduce length of | ||

| ||||

|

|

|

| the circuit. |

| 3. General overloading of power company | 3. Request a power check from the power | ||

| facilities. |

|

| company. |

|

|

|

| |

Motor overheats. | 1. Motor overloaded. |

| 1. Reduce load on motor. | |

| 2. Air circulation | through | the motor | 2. Clean off motor to provide normal air |

| restricted. |

|

| circulation. |

|

|

| ||

Motor stalls (resulting in blown fuses or | 1. Short circuit in motor or loose connec- | 1. Repair or replace connections on motor | ||

tripped circuit). | tions. |

|

| for loose or shorted terminals or worn |

|

|

|

| insulation. |

| 2. Low voltage. |

|

| 2. Correct the low voltage conditions. |

| 3. Incorrect fuses | or circuit | breakers in | 3. Install correct fuses or circuit breakers. |

| power line. |

|

|

|

| 4. Motor overloaded. |

| 4. Reduce load on motor. | |

|

|

| ||

Drums run backwards (G0450 only). | 1. Two of the power wires are reversed | 1. Switch two of the current carrying wires | ||

| (G0450 only). |

|

| at the main power block (G0450 only). |

|

|

|

|

|

Machine slows when sanding, making a | 1. |

|

| 1. Tighten |

squealing noise, especially on | 2. |

| 2. Replace | |

|

|

| ||

Loud repetitious noise coming from | 1. Pulley setscrews or keys are missing or | 1. Inspect keys and setscrews. Replace | ||

machine. | loose. |

|

| or tighten if necessary. |

| 2. Motor fan is hitting the cover. | 2. Adjust fan cover mounting position, | ||

|

|

|

| tighten fan, or shim fan cover. |

| 3. |

| 3. Replace | |

|

|

| ||

Vibration when sanding. | 1. Loose drum pillow bearings. | 1. Tighten drum pillow bearings. | ||

| 2. Worn drum pillow bearings. | 2. Replace drum pillow bearings. | ||

|

|

|

|

|

|

|

| G0449/G0450 37" Drum Sander | |