Drum Adjustments

Tools Needed: | Qty |

Hex Wrench 5mm | 1 |

Hex Wrench 4mm | 1 |

Wrench 19mm | 1 |

Wrench 10mm | 1 |

Wrenches/Sockets 14mm | 2 |

Measuring Tape | 1 |

Gauge Blocks (see Page 30) | 2 |

Feeler Gauge Set | 1 |

When adjusting the drums, they must be aligned in two

������������

���

����

���������

Figure 33. Drum perpendicular to feed direction.

������������

�������������

The drums can be adjusted in fine increments at the pillow bearings and in larger increments by using the table lift screws (Page 27).

While adjusting the drums, keep in mind that having the drums parallel to the conveyor belt is critical to the sanding operation. Care should be taken to make the tolerances as close as possible (within 0.002" from one side to the other) when adjusting the drum heights.

The tolerances for having the drum perpendicular to the feed direction are much more forgiving, even allowing up to 1⁄8" difference from one side to the other before causing problems.

To align the drums:

1.Disconnect power to the sander!

2.Open the top and

3.Remove the sandpaper from the drums.

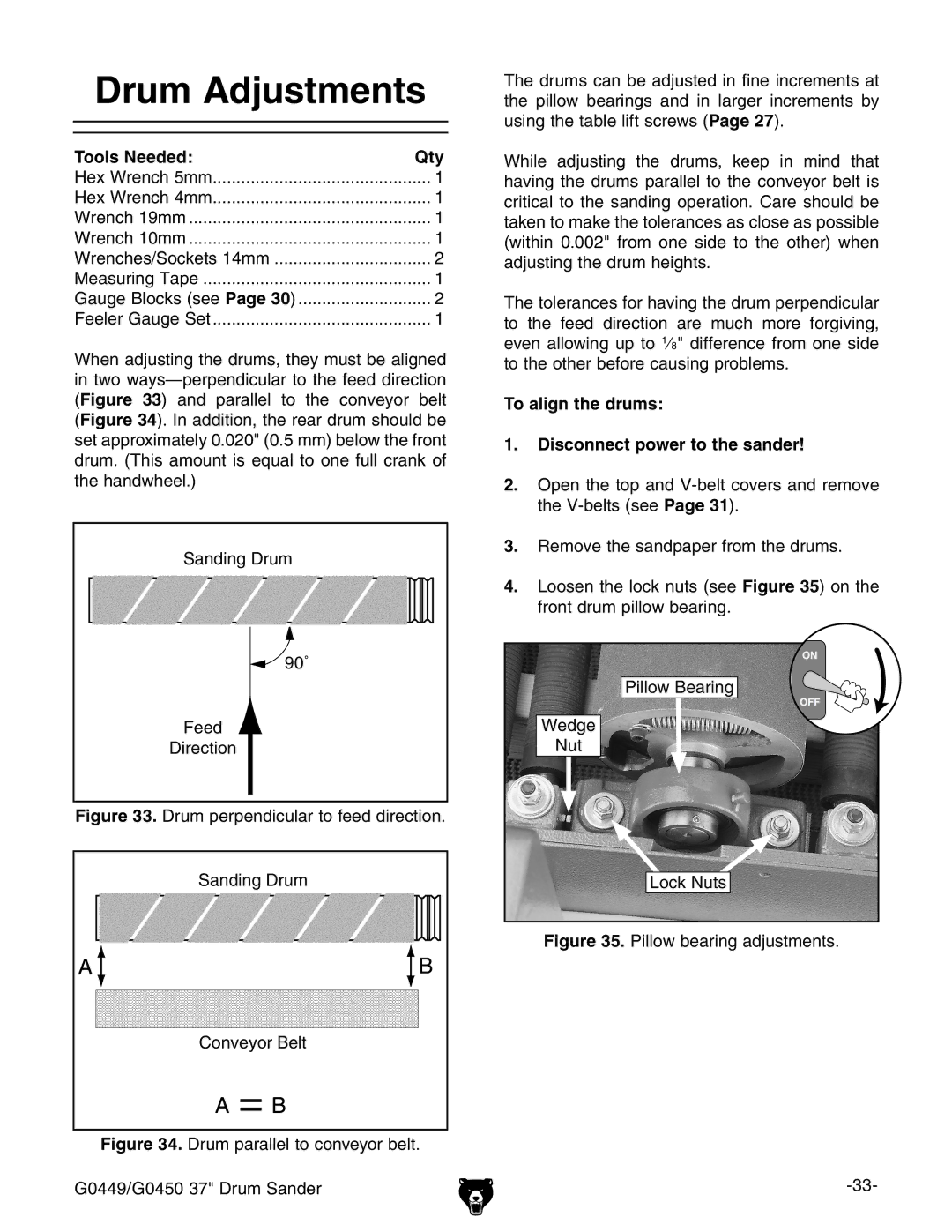

4.Loosen the lock nuts (see Figure 35) on the front drum pillow bearing.

Pillow Bearing

Wedge

Nut

Lock Nuts

Figure 35. Pillow bearing adjustments.

Figure 34. Drum parallel to conveyor belt.

G0449/G0450 37" Drum Sander |