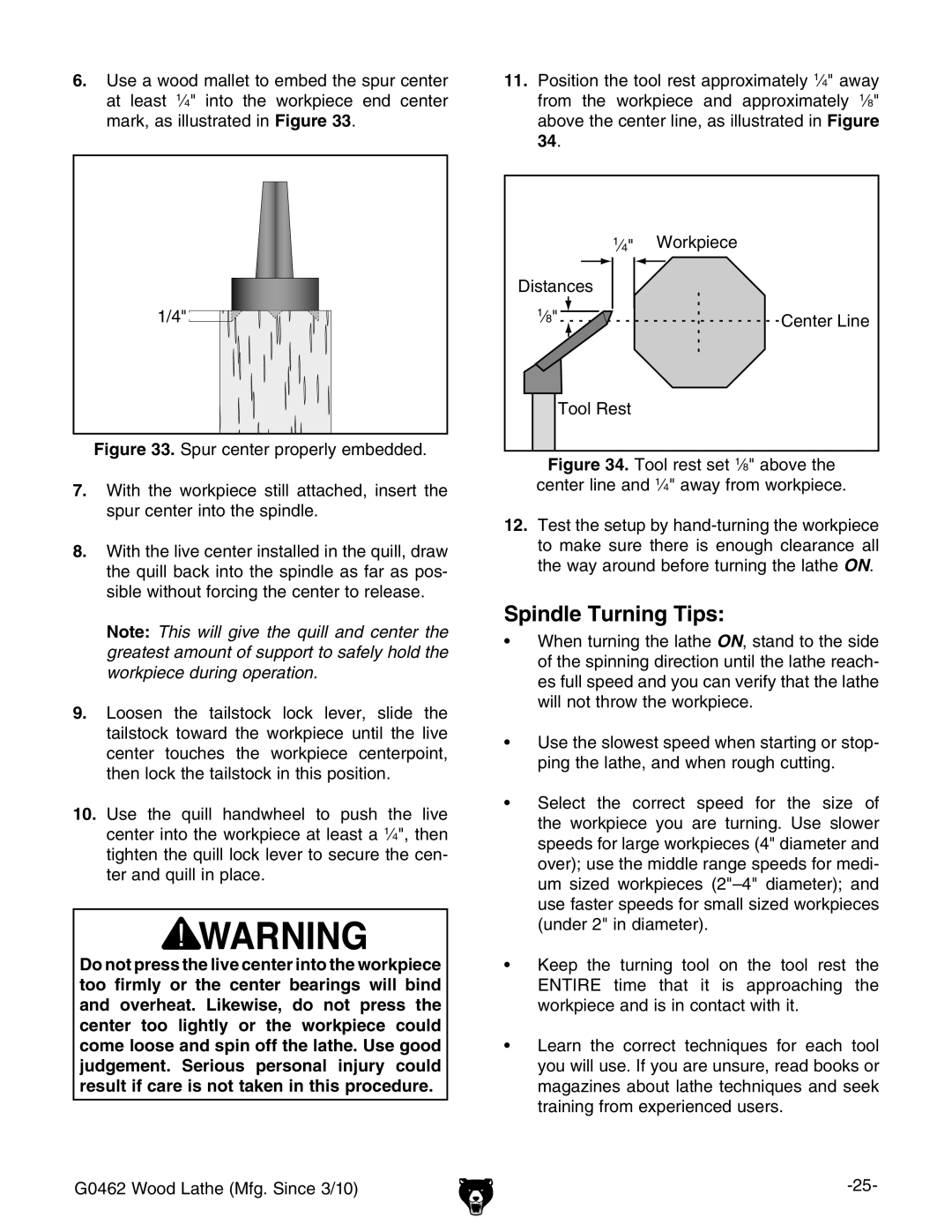

6.Use a wood mallet to embed the spur center at least 1⁄4" into the workpiece end center mark, as illustrated in Figure 33.

11.Position the tool rest approximately 1⁄4" away from the workpiece and approximately 1⁄8" above the center line, as illustrated in Figure 34.

1/4" ![]()

Figure 33. Spur center properly embedded.

7.With the workpiece still attached, insert the spur center into the spindle.

8.With the live center installed in the quill, draw the quill back into the spindle as far as pos- sible without forcing the center to release.

Note: This will give the quill and center the greatest amount of support to safely hold the workpiece during operation.

9.Loosen the tailstock lock lever, slide the tailstock toward the workpiece until the live center touches the workpiece centerpoint, then lock the tailstock in this position.

10.Use the quill handwheel to push the live center into the workpiece at least a 1⁄4", then tighten the quill lock lever to secure the cen- ter and quill in place.

Do not press the live center into the workpiece too firmly or the center bearings will bind and overheat. Likewise, do not press the center too lightly or the workpiece could come loose and spin off the lathe. Use good judgement. Serious personal injury could result if care is not taken in this procedure.

G0462 Wood Lathe (Mfg. Since 3/10)

1⁄4" Workpiece

Distances

1⁄8" | Center Line |

Tool Rest

Figure 34. Tool rest set 1⁄8" above the center line and 1⁄4" away from workpiece.

12.Test the setup by hand-turning the workpiece to make sure there is enough clearance all the way around before turning the lathe ON.

Spindle Turning Tips:

•When turning the lathe ON, stand to the side of the spinning direction until the lathe reach- es full speed and you can verify that the lathe will not throw the workpiece.

•Use the slowest speed when starting or stop- ping the lathe, and when rough cutting.

•Select the correct speed for the size of the workpiece you are turning. Use slower speeds for large workpieces (4" diameter and over); use the middle range speeds for medi- um sized workpieces

•Keep the turning tool on the tool rest the ENTIRE time that it is approaching the workpiece and is in contact with it.

•Learn the correct techniques for each tool you will use. If you are unsure, read books or magazines about lathe techniques and seek training from experienced users.