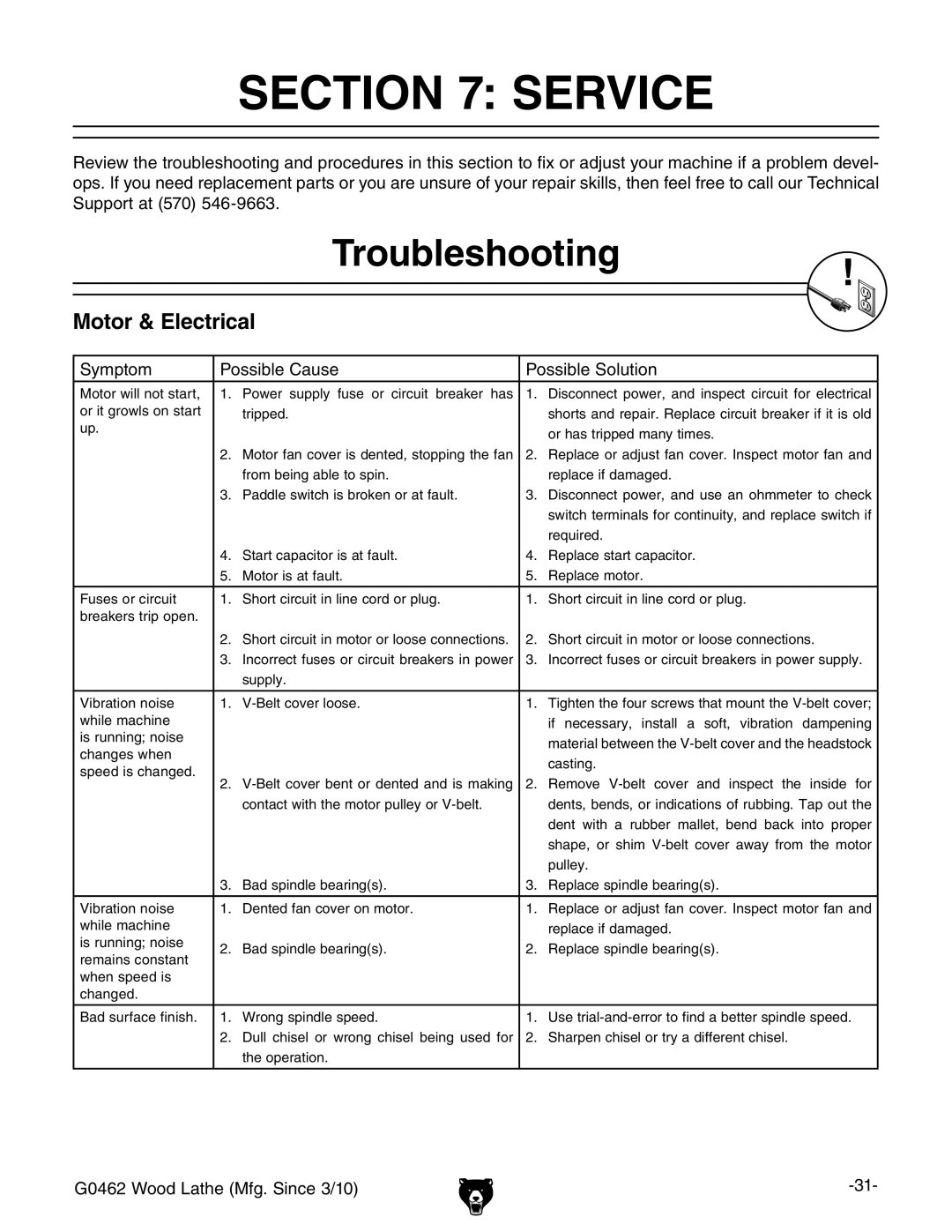

SECTION 7: SERVICE

Review the troubleshooting and procedures in this section to fix or adjust your machine if a problem devel- ops. If you need replacement parts or you are unsure of your repair skills, then feel free to call our Technical Support at (570)

Troubleshooting

Motor & Electrical

Symptom | Possible Cause | Possible Solution | |||

Motor will not start, | 1. | Power supply fuse or circuit breaker has | 1. | Disconnect power, and inspect circuit for electrical | |

or it growls on start |

| tripped. |

| shorts and repair. Replace circuit breaker if it is old | |

up. |

|

|

| or has tripped many times. | |

|

|

|

| ||

| 2. | Motor fan cover is dented, stopping the fan | 2. | Replace or adjust fan cover. Inspect motor fan and | |

|

| from being able to spin. |

| replace if damaged. | |

| 3. | Paddle switch is broken or at fault. | 3. | Disconnect power, and use an ohmmeter to check | |

|

|

|

| switch terminals for continuity, and replace switch if | |

|

|

|

| required. | |

| 4. | Start capacitor is at fault. | 4. | Replace start capacitor. | |

| 5. | Motor is at fault. | 5. | Replace motor. | |

|

|

|

|

| |

Fuses or circuit | 1. | Short circuit in line cord or plug. | 1. | Short circuit in line cord or plug. | |

breakers trip open. |

|

|

|

| |

| 2. | Short circuit in motor or loose connections. | 2. | Short circuit in motor or loose connections. | |

| 3. | Incorrect fuses or circuit breakers in power | 3. | Incorrect fuses or circuit breakers in power supply. | |

|

| supply. |

|

| |

|

|

|

|

| |

Vibration noise | 1. | 1. | Tighten the four screws that mount the | ||

while machine |

|

|

| if necessary, install a soft, vibration dampening | |

is running; noise |

|

|

| material between the | |

changes when |

|

|

| ||

|

|

| casting. | ||

speed is changed. |

|

|

| ||

2. | 2. | Remove | |||

| |||||

|

| contact with the motor pulley or |

| dents, bends, or indications of rubbing. Tap out the | |

|

|

|

| dent with a rubber mallet, bend back into proper | |

|

|

|

| shape, or shim | |

|

|

|

| pulley. | |

| 3. | Bad spindle bearing(s). | 3. | Replace spindle bearing(s). | |

|

|

|

|

| |

Vibration noise | 1. | Dented fan cover on motor. | 1. | Replace or adjust fan cover. Inspect motor fan and | |

while machine |

|

|

| replace if damaged. | |

is running; noise | 2. | Bad spindle bearing(s). | 2. | Replace spindle bearing(s). | |

remains constant | |||||

|

|

|

| ||

when speed is |

|

|

|

| |

changed. |

|

|

|

| |

|

|

|

|

| |

Bad surface finish. | 1. | Wrong spindle speed. | 1. | Use | |

| 2. | Dull chisel or wrong chisel being used for | 2. | Sharpen chisel or try a different chisel. | |

|

| the operation. |

|

| |

|

|

|

|

| |

G0462 Wood Lathe (Mfg. Since 3/10) |