Clean Up

The unpainted surfaces are coated with a waxy oil to protect them from corrosion during ship- ment. Remove this protective coating with a sol- vent cleaner or

Some parts may need to be removed before they can be thoroughly cleaned.

For optimum performance from your machine, make sure you clean all moving parts or slid- ing contact surfaces that are coated.

Avoid

Gasoline and petroleum products have low flash points and could cause an explosion or fire if used to clean machinery. DO NOT use gasoline or petroleum products to clean the machinery.

Many of the solvents commonly used to clean machinery can be toxic when inhaled or ingest- ed. Lack of ventilation while using these sol- vents could cause seri- ous personal health risks or fire. Take precautions from this hazard by only using cleaning solvents in a well ventilated area.

Site Considerations

Floor Load

Refer to the Machine Data Sheet for the weight and footprint specifications of your machine. Some residential floors may require additional reinforcement to support the machine, workpiece, and operator.

Minimum Working Clearances

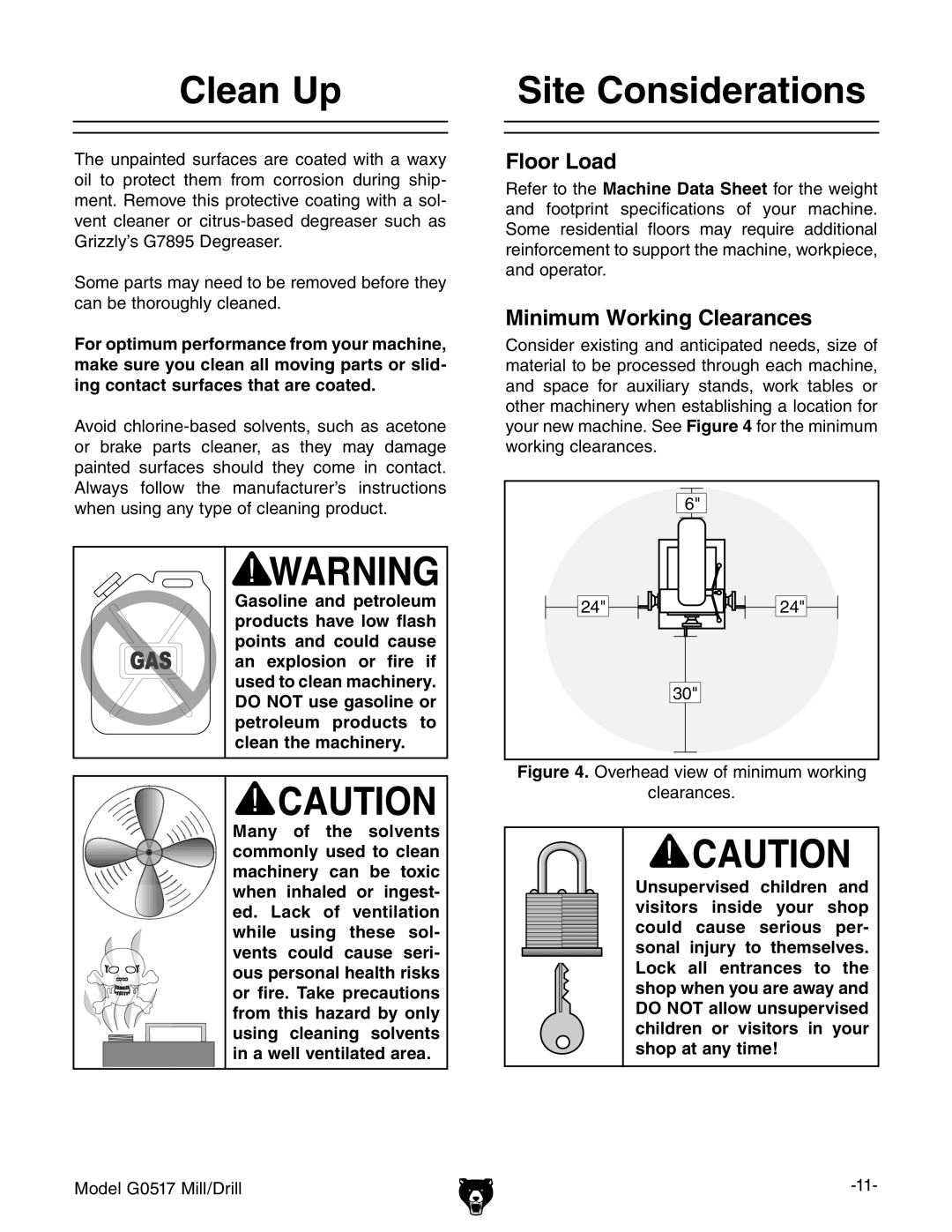

Consider existing and anticipated needs, size of material to be processed through each machine, and space for auxiliary stands, work tables or other machinery when establishing a location for your new machine. See Figure 4 for the minimum working clearances.

��

��� | ��� |

���

Figure 4. Overhead view of minimum working

clearances.

Unsupervised children and visitors inside your shop could cause serious per- sonal injury to themselves. Lock all entrances to the shop when you are away and DO NOT allow unsupervised children or visitors in your shop at any time!

Model G0517 Mill/Drill |