SECTION 6: MAINTENANCE

Always disconnect power to the machine before performing maintenance. Failure to do this may result in serious person- al injury.

Schedule

For optimum performance from your machine, follow this maintenance schedule and refer to any specific instructions given in this section.

Daily Check:

•Mill/drill is completely powered down at the end of use.

•Excess cutting fluids and chips have been removed and unpainted surfaces are dry and protected.

•Loose mounting bolts.

•Mill/drill is clean and lubricated.

•Worn or damaged wires.

•Any other unsafe condition.

Monthly Check:

•Gibs are adjusted properly.

Unpainted Cast Iron

Protect the unpainted cast iron surfaces on the table by removing vises and fixtures daily and by wiping the table clean after every

Keep tables

Lubrication

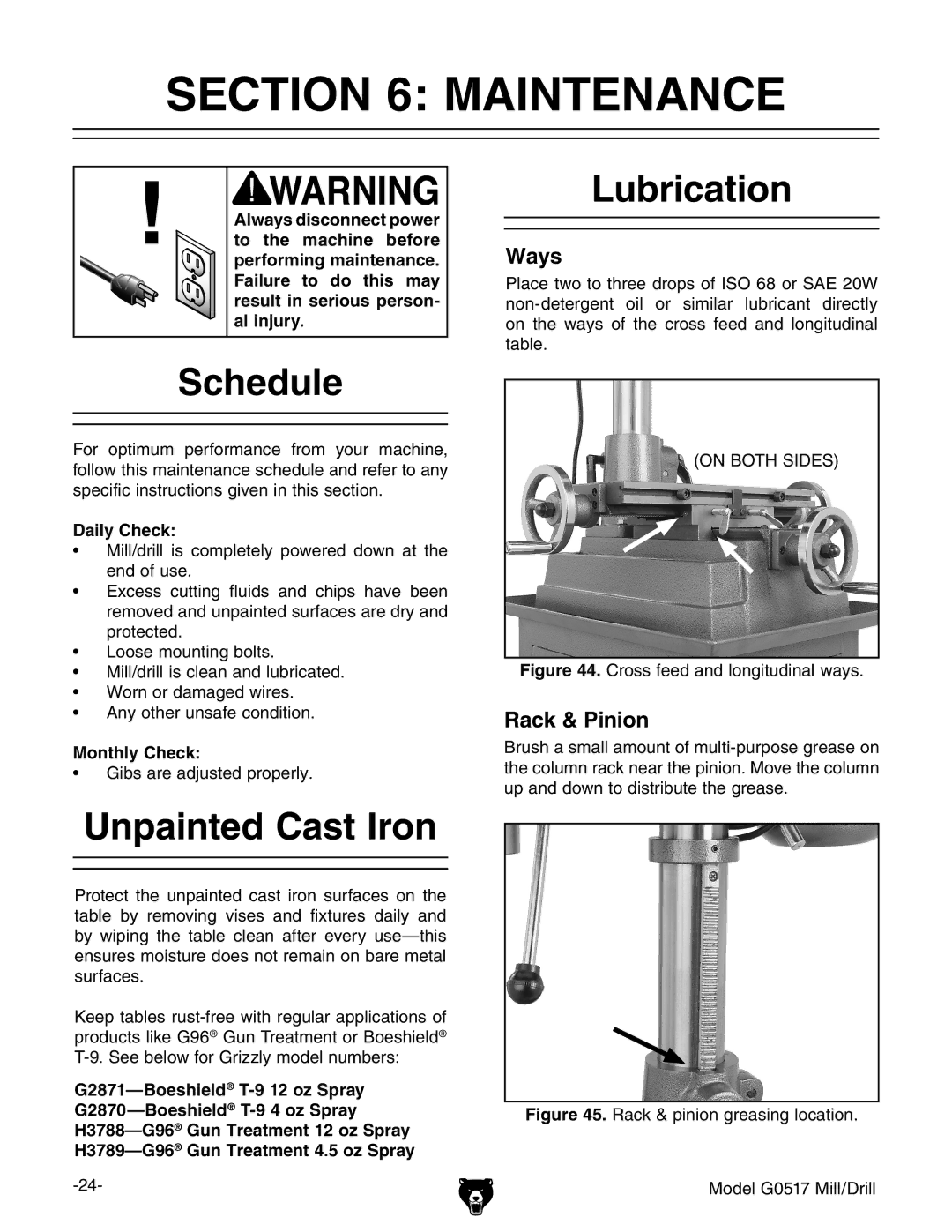

Ways

Place two to three drops of ISO 68 or SAE 20W

(ON BOTH SIDES)

Figure 44. Cross feed and longitudinal ways.

Rack & Pinion

Brush a small amount of