Blade Tensioning

NOTICE

To prolong blade life, release the tension on the blade if the machine will be idle for an extended period of time.

Proper blade tension reduces the risk of blade breakage and improves cutting performance.

To correctly tension the blade:

1.DISCONNECT BANDSAW FROM POWER!

2.Open the upper wheel door, and raise the blade post and upper blade guide assembly to the highest position.

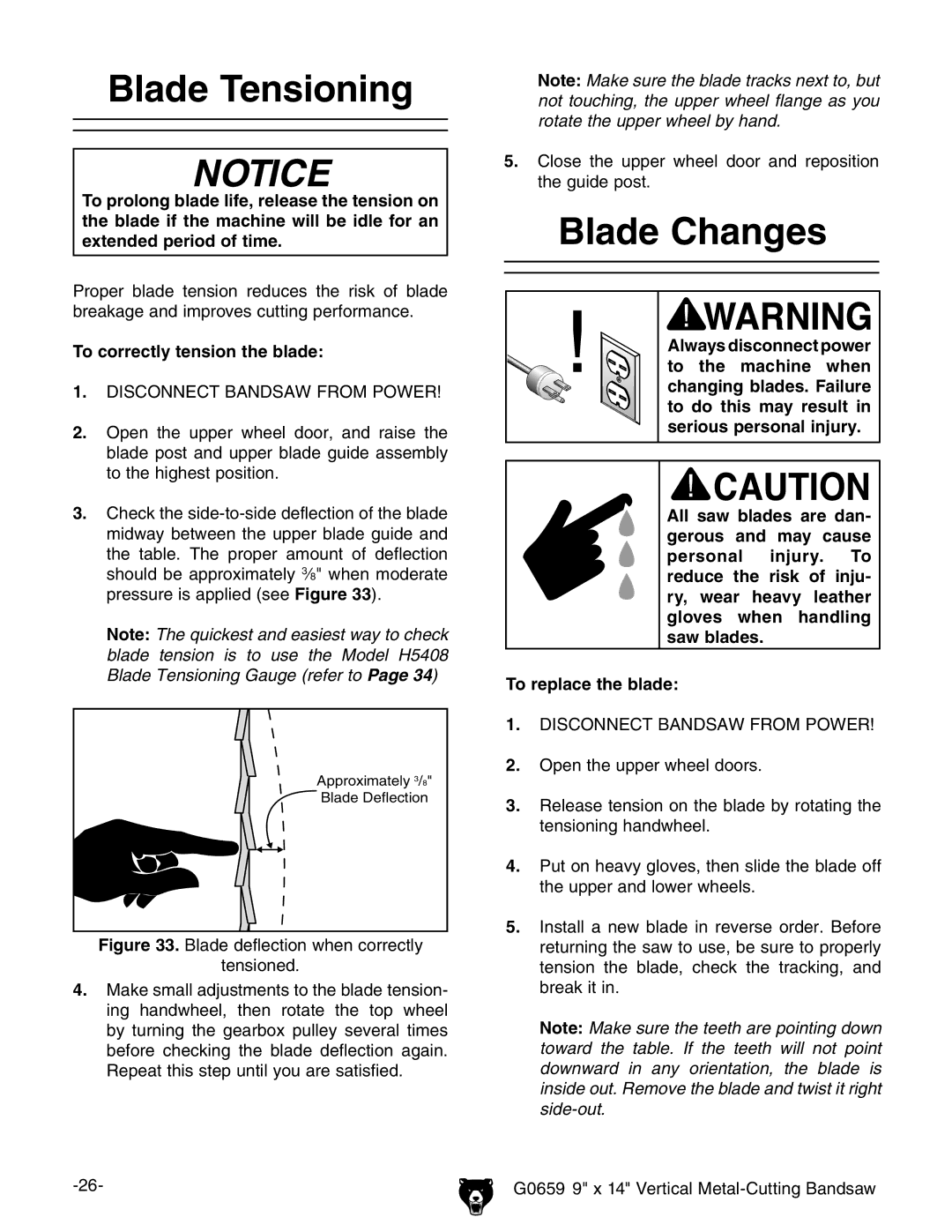

3.Check the

Note: The quickest and easiest way to check blade tension is to use the Model H5408 Blade Tensioning Gauge (refer to Page 34)

Figure 33. Blade deflection when correctly

tensioned.

4.Make small adjustments to the blade tension- ing handwheel, then rotate the top wheel by turning the gearbox pulley several times before checking the blade deflection again. Repeat this step until you are satisfied.

Note: Make sure the blade tracks next to, but not touching, the upper wheel flange as you rotate the upper wheel by hand.

5.Close the upper wheel door and reposition the guide post.

Blade Changes

Always disconnect power to the machine when changing blades. Failure to do this may result in serious personal injury.

All saw blades are dan- gerous and may cause personal injury. To reduce the risk of inju- ry, wear heavy leather gloves when handling saw blades.

To replace the blade:

1.DISCONNECT BANDSAW FROM POWER!

2.Open the upper wheel doors.

3.Release tension on the blade by rotating the tensioning handwheel.

4.Put on heavy gloves, then slide the blade off the upper and lower wheels.

5.Install a new blade in reverse order. Before returning the saw to use, be sure to properly tension the blade, check the tracking, and break it in.

Note: Make sure the teeth are pointing down toward the table. If the teeth will not point downward in any orientation, the blade is inside out. Remove the blade and twist it right

G0659 9" x 14" Vertical