Mounting to Shop

Floor

Although not required, we strongly recommend that you mount your new machine to the floor to prevent tipping. Because this is an optional step and floor materials may vary, floor mounting hard- ware is not included.

Bolting to Concrete Floors

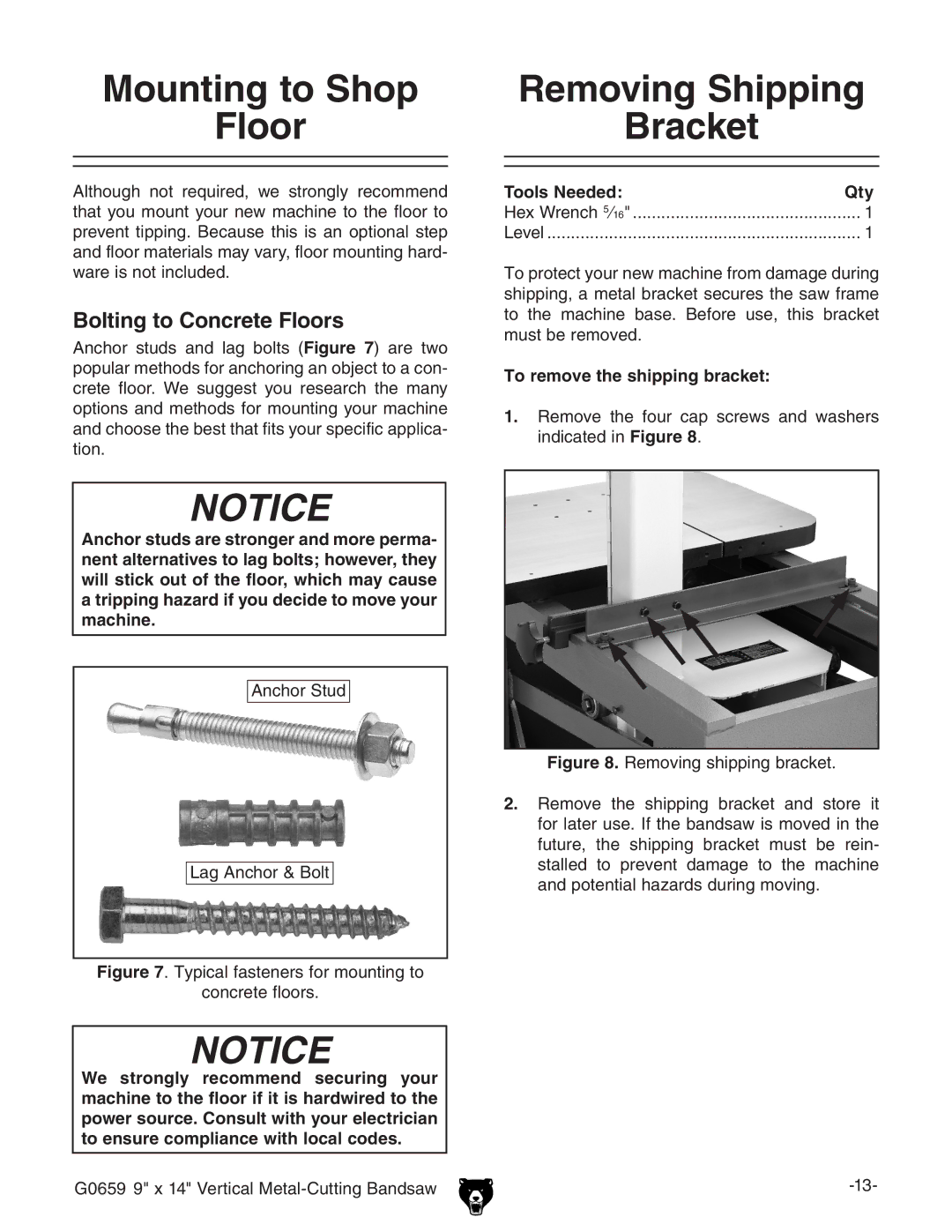

Anchor studs and lag bolts (Figure 7) are two popular methods for anchoring an object to a con- crete floor. We suggest you research the many options and methods for mounting your machine and choose the best that fits your specific applica- tion.

NOTICE

Anchor studs are stronger and more perma- nent alternatives to lag bolts; however, they will stick out of the floor, which may cause a tripping hazard if you decide to move your machine.

Anchor Stud

Lag Anchor & Bolt

Figure 7. Typical fasteners for mounting to

concrete floors.

NOTICE

We strongly recommend securing your machine to the floor if it is hardwired to the power source. Consult with your electrician to ensure compliance with local codes.

G0659 9" x 14" Vertical

Removing Shipping

Bracket

Tools Needed: | Qty |

Hex Wrench 5⁄16" | ................................................. 1 |

Level | 1 |

To protect your new machine from damage during shipping, a metal bracket secures the saw frame to the machine base. Before use, this bracket must be removed.

To remove the shipping bracket:

1.Remove the four cap screws and washers indicated in Figure 8.