blade tensioning

Blade Tensioning

Proper blade tension reduces the risk of blade breakage and improves cutting performance.

To correctly tension the blade:

1.DISCONNECT BANDSAW FROM POWER!

2.Open the upper wheel door, and raise the blade post and upper blade guide assembly to the highest position.

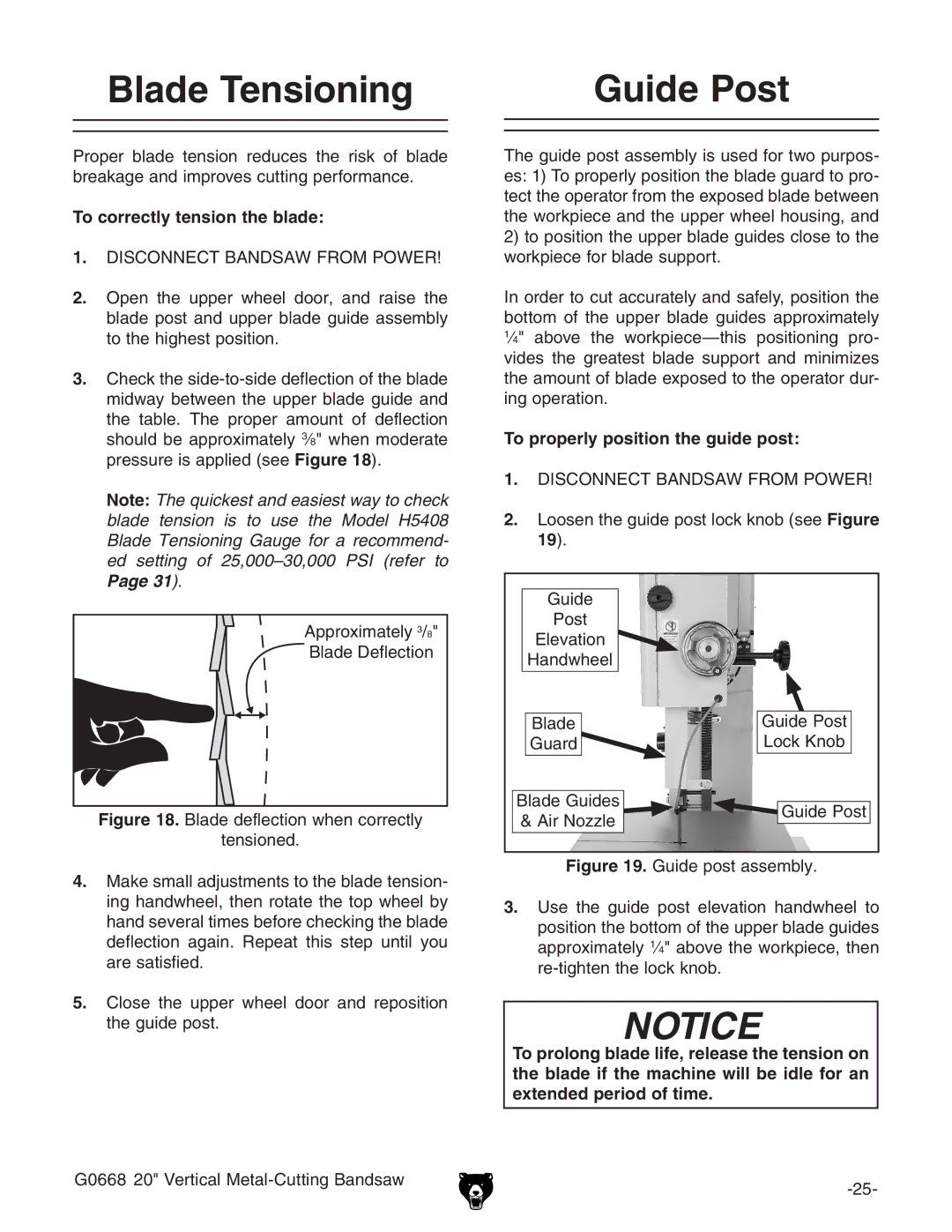

3.Check the

Note: The quickest and easiest way to check blade tension is to use the Model H5408 Blade Tensioning Gauge for a recommend- ed setting of

������������������

����������������

Figure 18. Blade deflection when correctly

tensioned.

4.Make small adjustments to the blade tension- ing handwheel, then rotate the top wheel by hand several times before checking the blade deflection again. Repeat this step until you are satisfied.

5.Close the upper wheel door and reposition the guide post.

Guide Post

The guide post assembly is used for two purpos- es: 1) To properly position the blade guard to pro- tect the operator from the exposed blade between the workpiece and the upper wheel housing, and

2)to position the upper blade guides close to the workpiece for blade support.

In order to cut accurately and safely, position the bottom of the upper blade guides approximately

1⁄4" above the

To properly position the guide post:

1.DISCONNECT BANDSAW FROM POWER!

2.Loosen the guide post lock knob (see Figure 19).

Guide

Post

Elevation

Handwheel

| Blade |

|

| Guide Post |

| |

| Guard |

| Lock Knob |

| ||

|

|

|

|

|

| |

|

|

|

|

|

|

|

Blade Guides |

|

|

|

| ||

| Guide Post | |||||

& Air Nozzle |

|

| ||||

|

|

|

| |||

Figure 19. Guide post assembly.

3.Use the guide post elevation handwheel to position the bottom of the upper blade guides approximately 1⁄4" above the workpiece, then re-tighten the lock knob.

NOTICE

To prolong blade life, release the tension on the blade if the machine will be idle for an extended period of time.

G0668 20" Vertical | |

|