4.Loosen the welding clamps by pulling the lock levers down.

5.Position the back of one blade end evenly against the back of the welding clamp so that the end is midway between the two clamps, then rotate that lock lever all the way up to hold the blade end in place (see Figure 29).

Welding

BladeClamp

End

Lock Lever![]()

Figure 29. Blade end properly position in

welding clamp and locked in place.

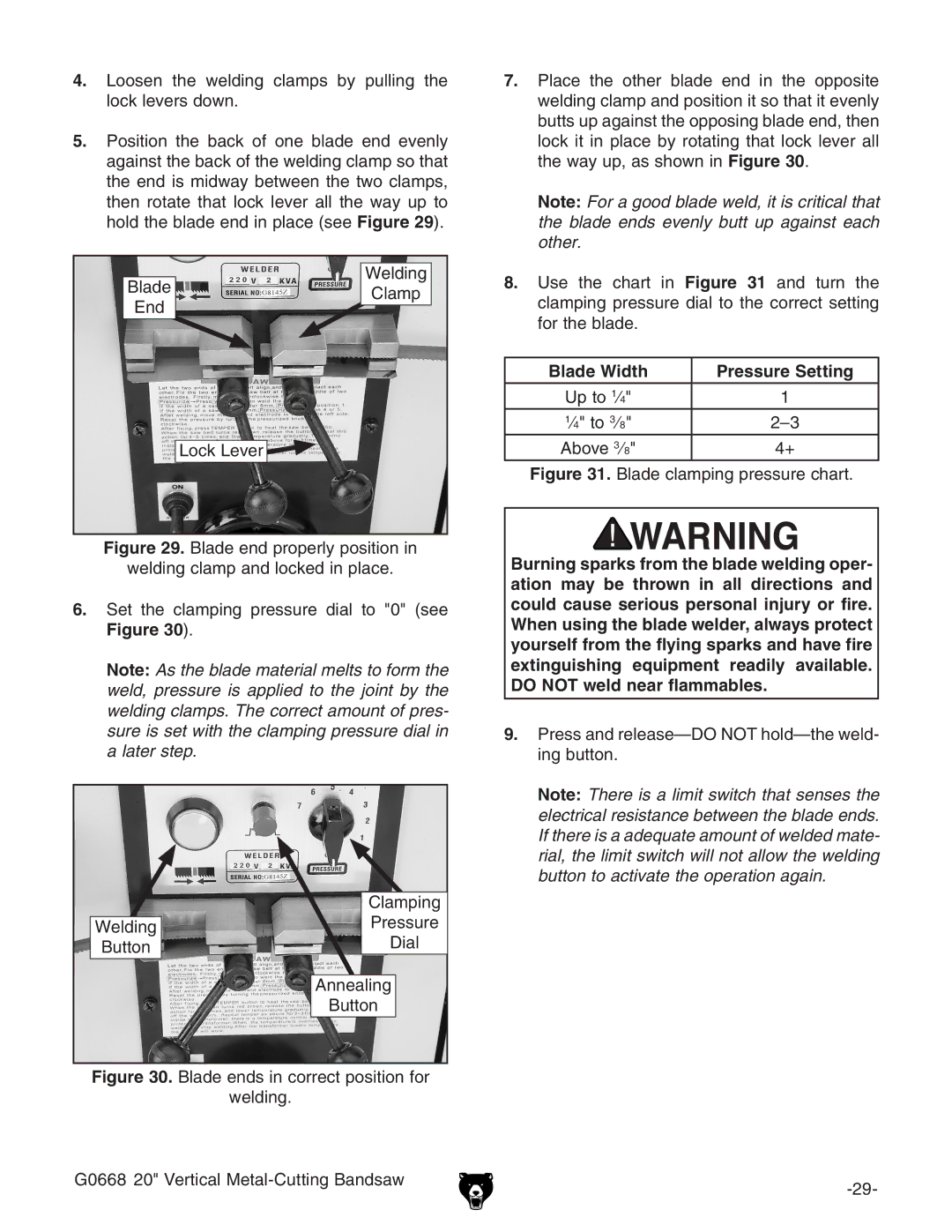

6.Set the clamping pressure dial to "0" (see Figure 30).

Note: As the blade material melts to form the weld, pressure is applied to the joint by the welding clamps. The correct amount of pres- sure is set with the clamping pressure dial in a later step.

|

|

|

|

|

|

|

|

|

| Clamping | |

|

|

|

| Pressure | |

| Welding |

|

| ||

| Button |

|

| Dial | |

|

|

|

|

| |

|

|

|

|

| |

|

|

| Annealing |

| |

|

|

| Button |

| |

|

|

|

|

|

|

Figure 30. Blade ends in correct position for

welding.

G0668 20" Vertical Metal-Cutting Bandsaw

7.Place the other blade end in the opposite welding clamp and position it so that it evenly butts up against the opposing blade end, then lock it in place by rotating that lock lever all the way up, as shown in Figure 30.

Note: For a good blade weld, it is critical that the blade ends evenly butt up against each other.

8.Use the chart in Figure 31 and turn the clamping pressure dial to the correct setting for the blade.

Blade Width | Pressure Setting |

Up to 1⁄4" | 1 |

1⁄4" to 3⁄8" | |

Above 3⁄8" | 4+ |

Figure 31. Blade clamping pressure chart.

Burning sparks from the blade welding oper- ation may be thrown in all directions and could cause serious personal injury or fire. When using the blade welder, always protect yourself from the flying sparks and have fire extinguishing equipment readily available. DO NOT weld near flammables.

9.Press and

Note: There is a limit switch that senses the electrical resistance between the blade ends. If there is a adequate amount of welded mate- rial, the limit switch will not allow the welding button to activate the operation again.