wheel alignment

Wheel Alignment

�����

Materials Needed: | Qty |

671⁄4" Long 2x4 | 1 |

Tools Needed: | Qty |

Wrench 12mm | 1 |

Wrench 17mm | 1 |

Wrench 21mm | 1 |

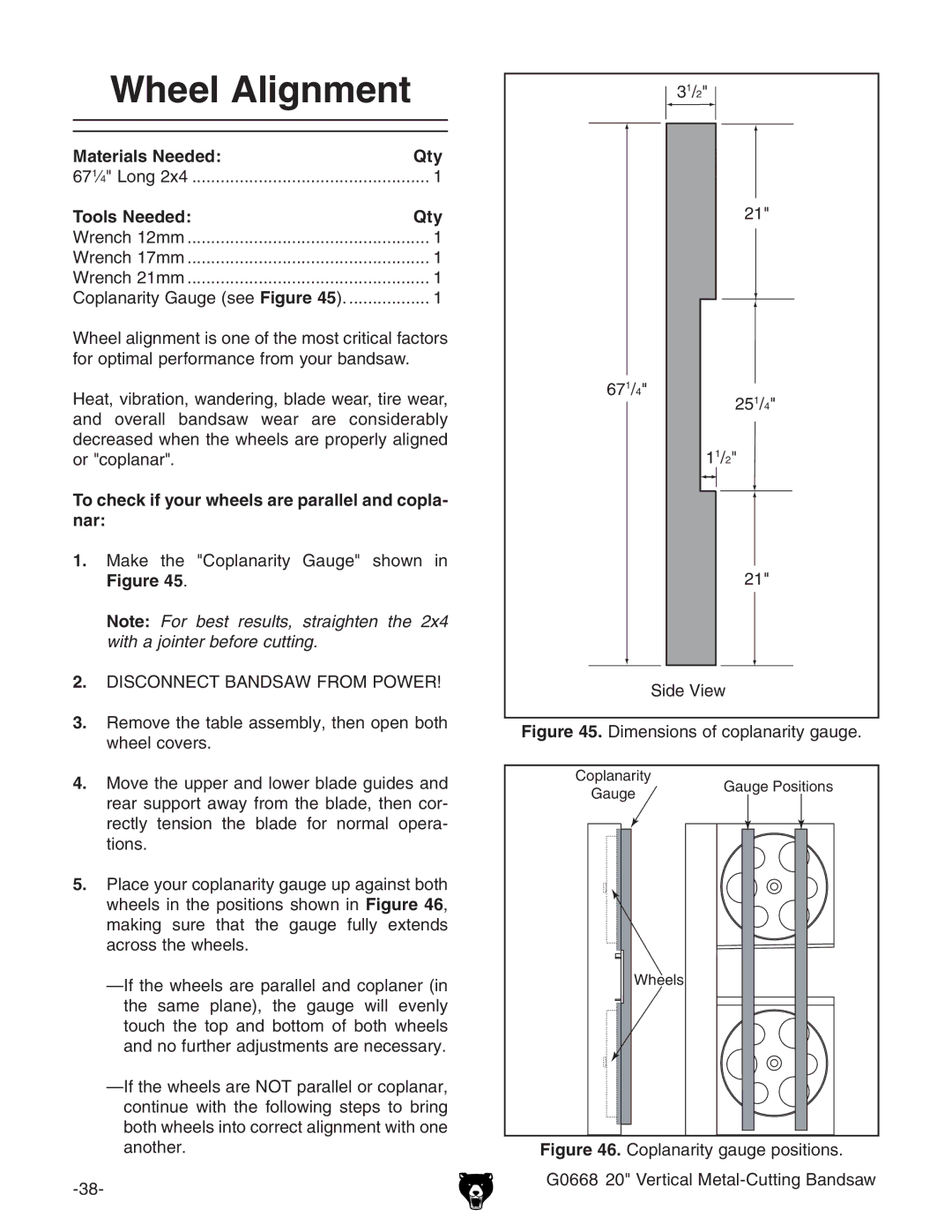

Coplanarity Gauge (see Figure 45) | 1 |

Wheel alignment is one of the most critical factors for optimal performance from your bandsaw.

Heat, vibration, wandering, blade wear, tire wear, and overall bandsaw wear are considerably decreased when the wheels are properly aligned

������

���

������

or "coplanar".

To check if your wheels are parallel and copla- nar:

1.Make the "Coplanarity Gauge" shown in Figure 45.

Note: For best results, straighten the 2x4 with a jointer before cutting.

2.DISCONNECT BANDSAW FROM POWER!

3.Remove the table assembly, then open both wheel covers.

4.Move the upper and lower blade guides and rear support away from the blade, then cor- rectly tension the blade for normal opera- tions.

5.Place your coplanarity gauge up against both wheels in the positions shown in Figure 46, making sure that the gauge fully extends across the wheels.

�����

���

���������

Figure 45. Dimensions of coplanarity gauge.

�����������

��������������������

������