blade welding

Blade Welding

Being able to quickly and safely weld a bandsaw blade comes in handy for the following situa- tions:

•To repair a broken blade that is still sharp and useful.

•To fabricate a new blade from a larger sec- tion of blade material to fit your bandsaw.

•To

Your metal cutting bandsaw is equipped with a blade welder that uses electrical resistance to heat and fuse the blade ends together. This process leaves the joint brittle, so it needs to be annealed after welding to give it strength and flex- ibility.

The electric current that flows through the blade welder during operation could cause serious personal injury or death. To avoid the risk of electrocution, never touch the blade or any metal part of the machine dur- ing blade welding or annealing.

To weld the ends of bandsaw together:

1.Turn the bandsaw motor OFF.

2.Place the blade evenly against the back of the blade shear and firmly pull the handle down to square off the blade end (see Figure 26).

Figure 26. Using the blade shear to cut the

blade.

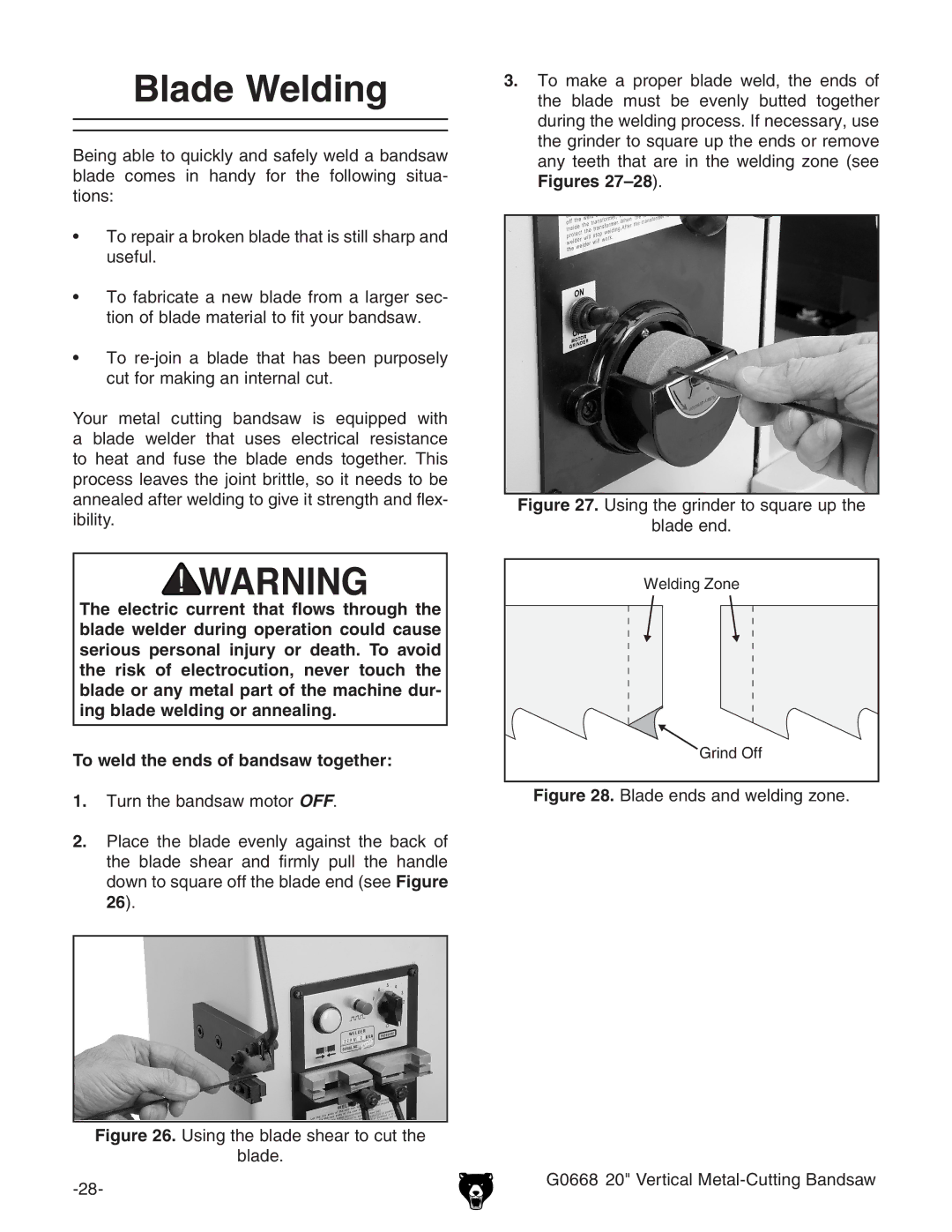

3.To make a proper blade weld, the ends of the blade must be evenly butted together during the welding process. If necessary, use the grinder to square up the ends or remove any teeth that are in the welding zone (see Figures 27–28).

Figure 27. Using the grinder to square up the

blade end.

������������

���������