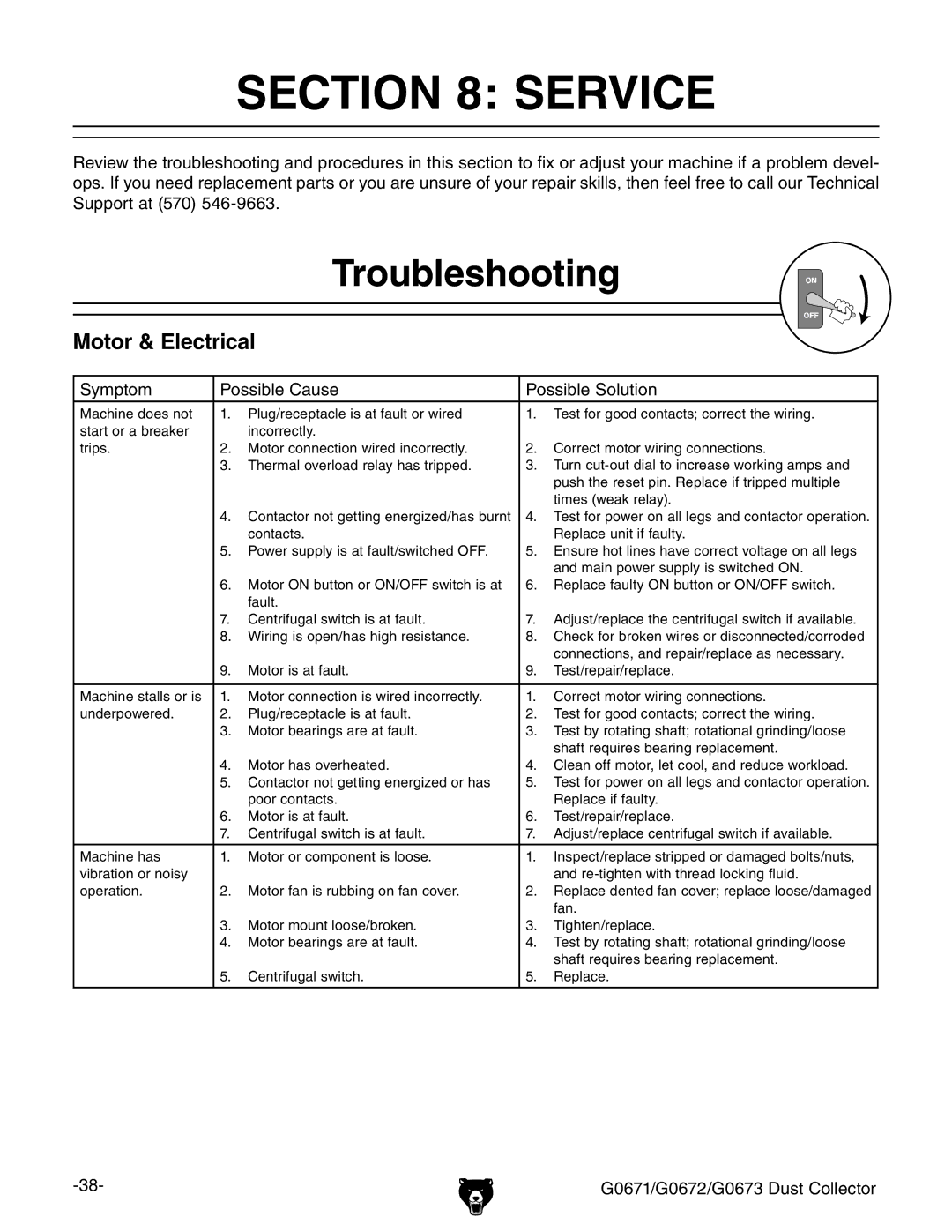

SECTION 8: SERVICE

Review the troubleshooting and procedures in this section to fix or adjust your machine if a problem devel- ops. If you need replacement parts or you are unsure of your repair skills, then feel free to call our Technical Support at (570)

Troubleshooting

Motor & Electrical

Symptom | Possible Cause | Possible Solution | ||

Machine does not | 1. | Plug/receptacle is at fault or wired | 1. | Test for good contacts; correct the wiring. |

start or a breaker |

| incorrectly. |

|

|

trips. | 2. | Motor connection wired incorrectly. | 2. | Correct motor wiring connections. |

| 3. | Thermal overload relay has tripped. | 3. | Turn |

|

|

|

| push the reset pin. Replace if tripped multiple |

|

|

|

| times (weak relay). |

| 4. | Contactor not getting energized/has burnt | 4. | Test for power on all legs and contactor operation. |

|

| contacts. |

| Replace unit if faulty. |

| 5. | Power supply is at fault/switched OFF. | 5. | Ensure hot lines have correct voltage on all legs |

|

|

|

| and main power supply is switched ON. |

| 6. | Motor ON button or ON/OFF switch is at | 6. | Replace faulty ON button or ON/OFF switch. |

|

| fault. |

|

|

| 7. | Centrifugal switch is at fault. | 7. | Adjust/replace the centrifugal switch if available. |

| 8. | Wiring is open/has high resistance. | 8. | Check for broken wires or disconnected/corroded |

|

|

|

| connections, and repair/replace as necessary. |

| 9. | Motor is at fault. | 9. | Test/repair/replace. |

|

|

|

|

|

Machine stalls or is | 1. | Motor connection is wired incorrectly. | 1. | Correct motor wiring connections. |

underpowered. | 2. | Plug/receptacle is at fault. | 2. | Test for good contacts; correct the wiring. |

| 3. | Motor bearings are at fault. | 3. | Test by rotating shaft; rotational grinding/loose |

|

|

|

| shaft requires bearing replacement. |

| 4. | Motor has overheated. | 4. | Clean off motor, let cool, and reduce workload. |

| 5. | Contactor not getting energized or has | 5. | Test for power on all legs and contactor operation. |

|

| poor contacts. |

| Replace if faulty. |

| 6. | Motor is at fault. | 6. | Test/repair/replace. |

| 7. | Centrifugal switch is at fault. | 7. | Adjust/replace centrifugal switch if available. |

|

|

|

|

|

Machine has | 1. | Motor or component is loose. | 1. | Inspect/replace stripped or damaged bolts/nuts, |

vibration or noisy |

|

|

| and |

operation. | 2. | Motor fan is rubbing on fan cover. | 2. | Replace dented fan cover; replace loose/damaged |

|

|

|

| fan. |

| 3. | Motor mount loose/broken. | 3. | Tighten/replace. |

| 4. | Motor bearings are at fault. | 4. | Test by rotating shaft; rotational grinding/loose |

|

|

|

| shaft requires bearing replacement. |

| 5. | Centrifugal switch. | 5. | Replace. |

|

|

|

|

|

G0671/G0672/G0673 Dust Collector |