4.Remove the springs that are in the holes left by the setscrews. See Figure 22.

5.Check for any dirt or grit. Clean the springs and setscrews if dirty.

6.Screw the three

7.Screw the light pressure setscrew until it is approximately 1⁄4" above the head casting. The feed chain applies additional tension to the right side of the outfeed roller, so the pressure added by the setscrew need not be as high.

Pressure Setscrew |

|

Pressure Spring |

|

Roller |

|

Check Nut | Height Setscrew |

Figure 22. Roller pressure assembly.

Bed Rollers

The bed rollers ease stock movement through the planer. The height of the bed rollers will vary depending on the types of wood you will be plan- ing. When planing rough stock, set the rollers slightly high to keep the lumber from dragging along the bed. However, snipe may be unavoid- able. Smooth lumber should be planed with the rollers set just above the plane of the table. This will minimize snipe.

TO ADJUST THE BED ROLLERS:

1.Ensure that power is disconnected and lay a high quality straightedge across both table rollers. Use a try square to keep the straight- edge perpendicular to the table.

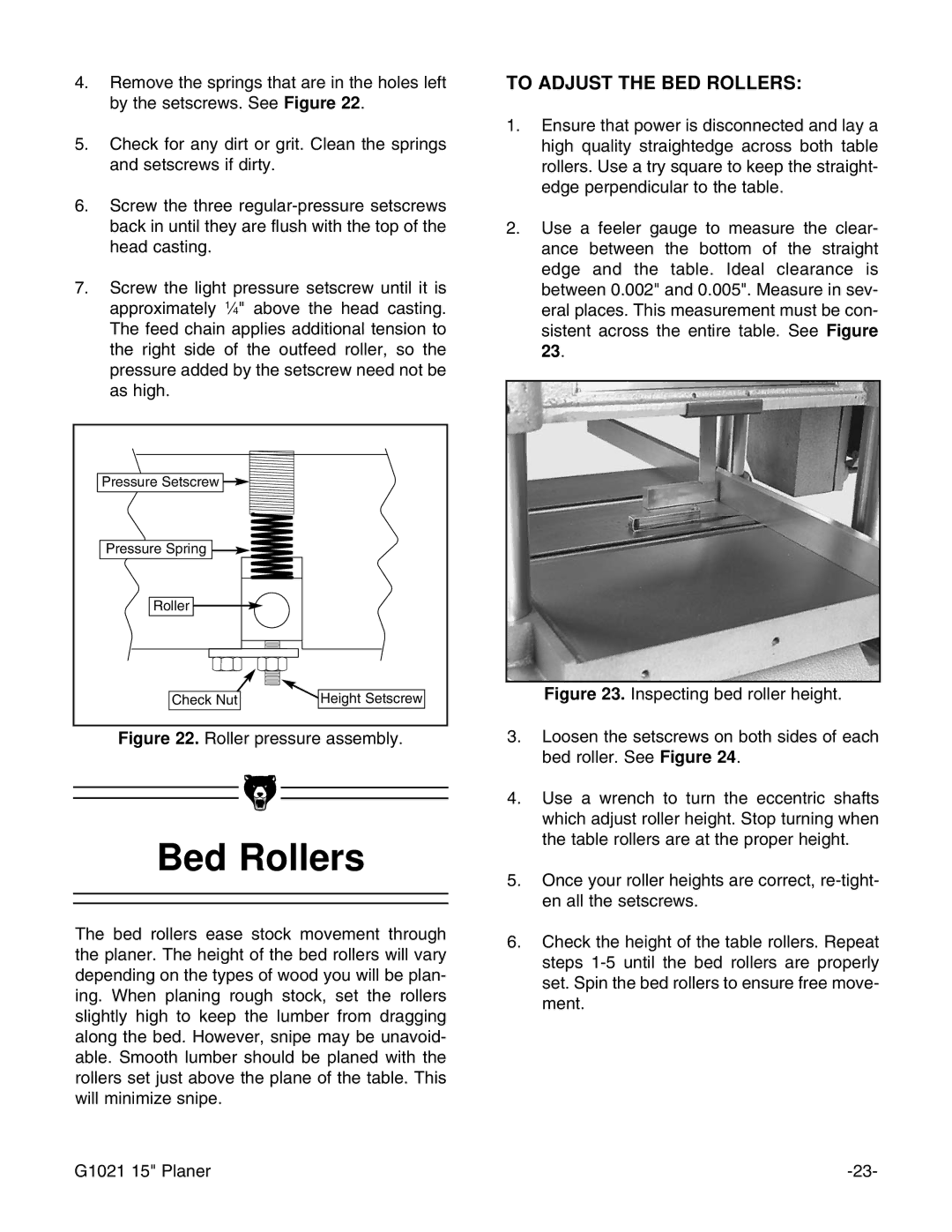

2.Use a feeler gauge to measure the clear- ance between the bottom of the straight edge and the table. Ideal clearance is between 0.002" and 0.005". Measure in sev- eral places. This measurement must be con- sistent across the entire table. See Figure 23.

Figure 23. Inspecting bed roller height.

3.Loosen the setscrews on both sides of each bed roller. See Figure 24.

4.Use a wrench to turn the eccentric shafts which adjust roller height. Stop turning when the table rollers are at the proper height.

5.Once your roller heights are correct, re-tight- en all the setscrews.

6.Check the height of the table rollers. Repeat steps 1-5 until the bed rollers are properly set. Spin the bed rollers to ensure free move- ment.

G1021 15" Planer |