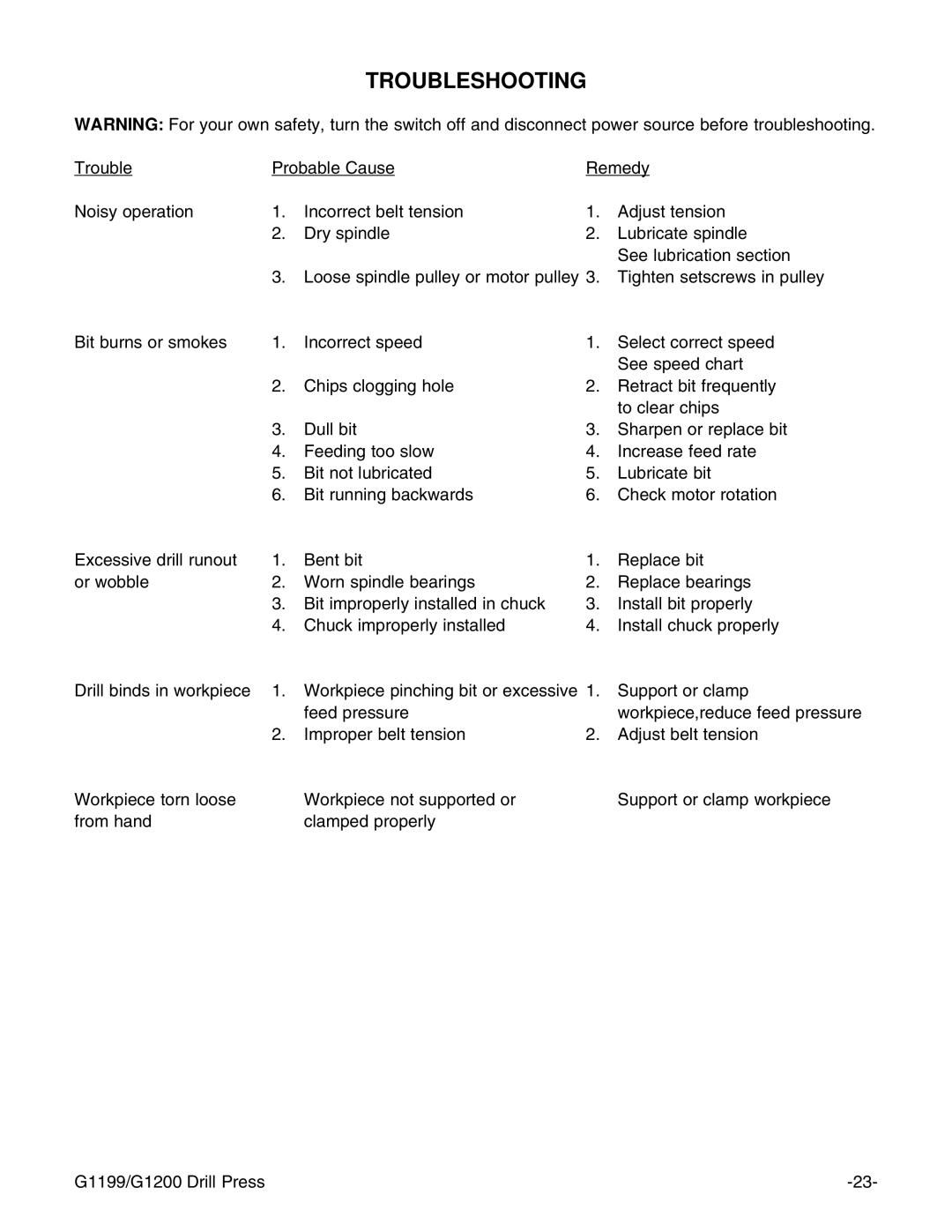

TROUBLESHOOTING

WARNING: For your own safety, turn the switch off and disconnect power source before troubleshooting.

Trouble | Probable Cause | Remedy | ||

Noisy operation | 1. | Incorrect belt tension | 1. | Adjust tension |

| 2. | Dry spindle | 2. | Lubricate spindle |

|

|

|

| See lubrication section |

| 3. | Loose spindle pulley or motor pulley 3. | Tighten setscrews in pulley | |

Bit burns or smokes | 1. | Incorrect speed | 1. | Select correct speed |

|

|

|

| See speed chart |

| 2. | Chips clogging hole | 2. | Retract bit frequently |

|

|

|

| to clear chips |

| 3. | Dull bit | 3. | Sharpen or replace bit |

| 4. | Feeding too slow | 4. | Increase feed rate |

| 5. | Bit not lubricated | 5. | Lubricate bit |

| 6. | Bit running backwards | 6. | Check motor rotation |

Excessive drill runout | 1. | Bent bit | 1. | Replace bit |

or wobble | 2. | Worn spindle bearings | 2. | Replace bearings |

| 3. | Bit improperly installed in chuck | 3. | Install bit properly |

| 4. | Chuck improperly installed | 4. | Install chuck properly |

Drill binds in workpiece | 1. | Workpiece pinching bit or excessive | 1. | Support or clamp |

|

| feed pressure |

| workpiece,reduce feed pressure |

| 2. | Improper belt tension | 2. | Adjust belt tension |

Workpiece torn loose |

| Workpiece not supported or |

| Support or clamp workpiece |

from hand |

| clamped properly |

|

|

G1199/G1200 Drill Press |