10.The finished diameter of the shoulder should be .001'' larger than the diameter of the recess in the chuck. This is a critical step in minimizing chuck

11.Install the chuck and check for runout.

If the runout is still excessive, the back of the chuck will need to be resurfaced. To resurface the back of the chuck:

1.Using the

2.Clamp the

3.Remove approximately .005'' from the mat- ing surface on the back of the chuck.

4.Install the

Tailstock

The tailstock on the Model G4000 is aligned at the factory with the headstock. You may want to take the time to ensure that the tailstock is aligned to your own desired tolerances. To align the tailstock:

1.Center drill a 6'' piece of bar stock on both ends.

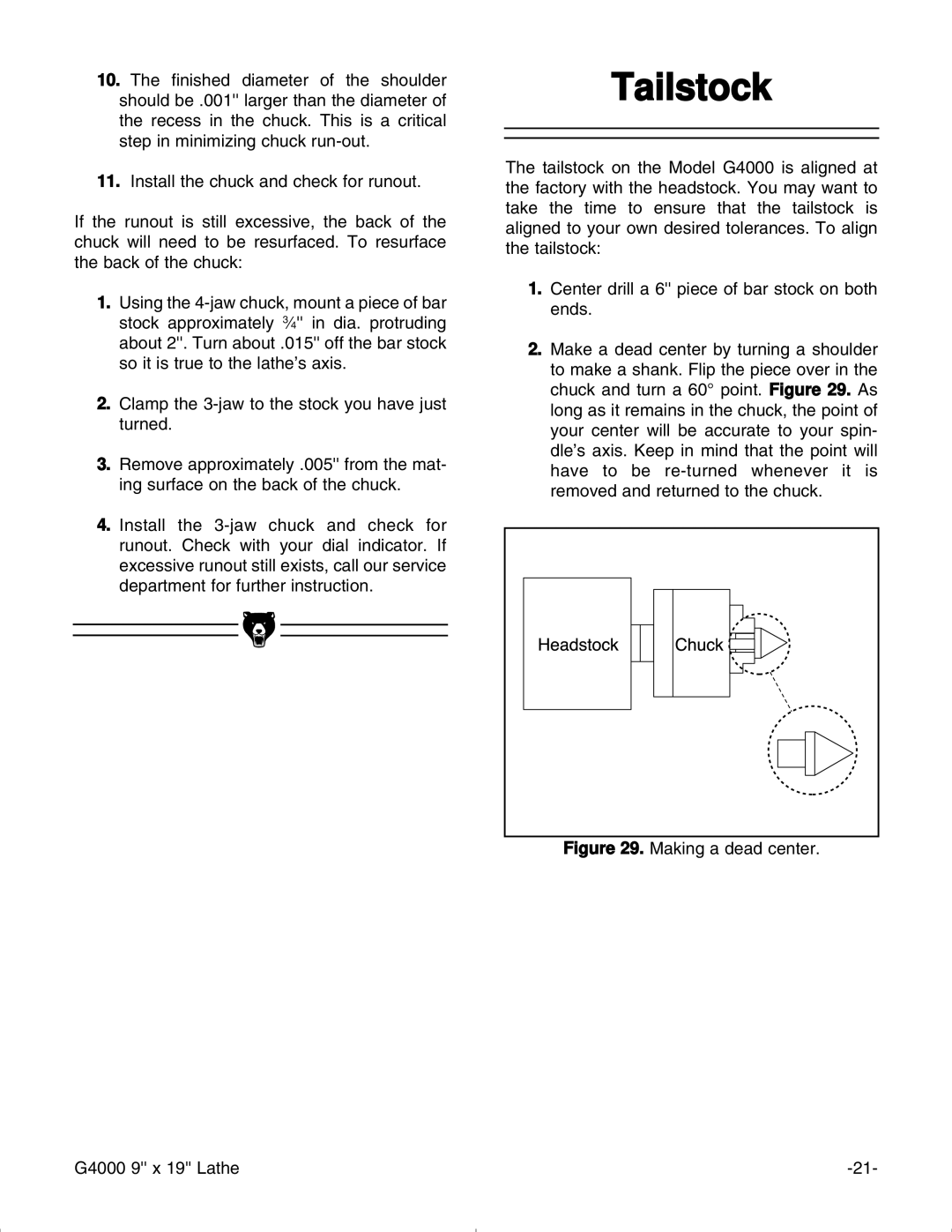

2.Make a dead center by turning a shoulder to make a shank. Flip the piece over in the chuck and turn a 60° point. Figure 29. As long as it remains in the chuck, the point of your center will be accurate to your spin- dle’s axis. Keep in mind that the point will have to be

Figure 29. Making a dead center.

G4000 9'' x 19'' Lathe |