Motor - The bearings used in the motor are shielded and lubricated for life.

Ways, Slides - Apply oil to the ways and slides after each use. Wipe the ways with a clean rag prior to lubrication to ensure that no grime is car- ried along with your lubricant into

Lead Screw - Be sure to lubricate the leadscrew and the leadscrew bearing at the tailstock end of the lathe. Figure 39.

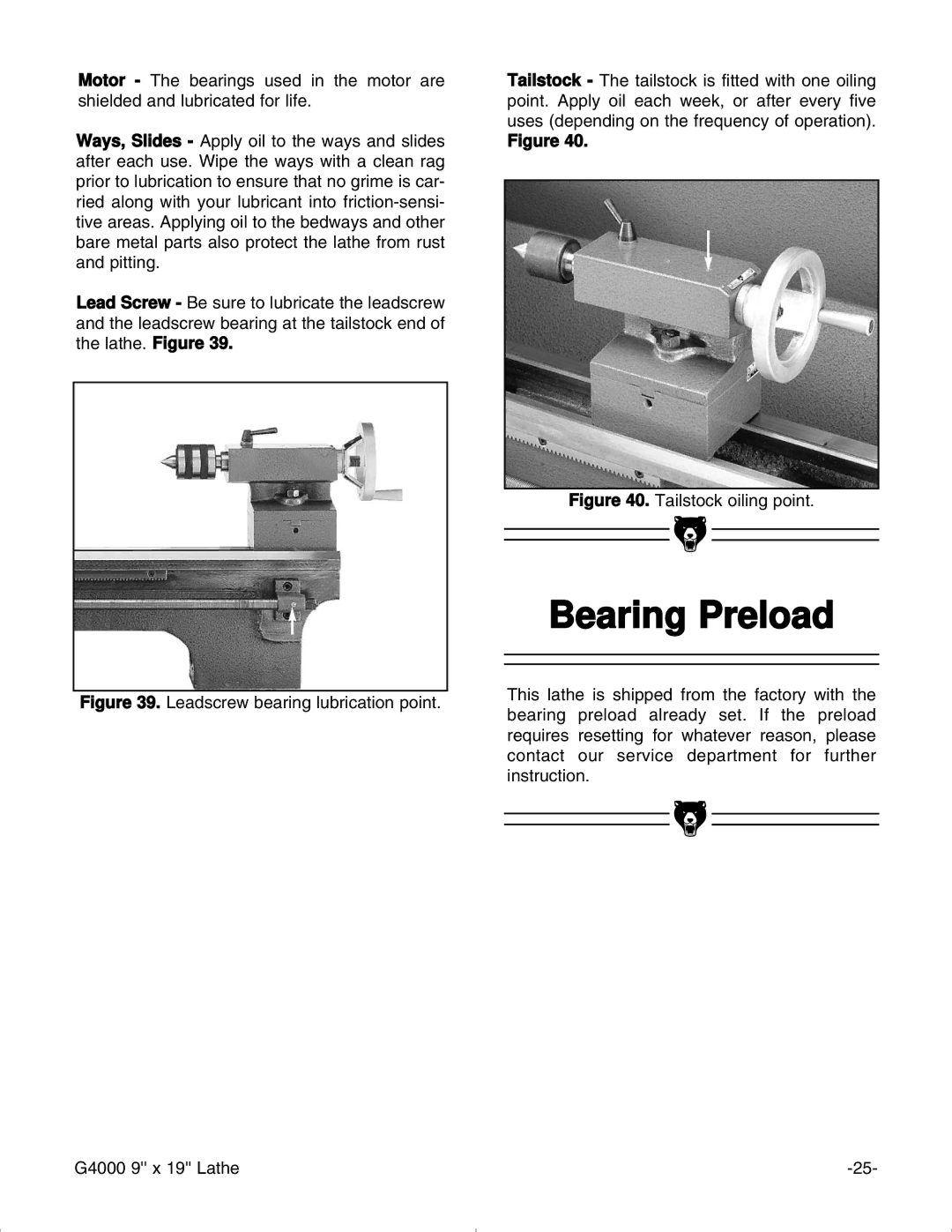

Tailstock - The tailstock is fitted with one oiling point. Apply oil each week, or after every five uses (depending on the frequency of operation).

Figure 40.

Figure 40. Tailstock oiling point.

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

| Bearing Preload | |||

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

| This lathe is shipped from the factory with the | |||

Figure 39. | Leadscrew bearing lubrication point. | |||||

|

|

| ||||

bearing preload already set. If the preload requires resetting for whatever reason, please contact our service department for further instruction.

G4000 9'' x 19'' Lathe |