Chuck Runout

If your lathe use requires a higher level of accu- racy, you may find it necessary to

1.Mount a piece of bar stock in the chuck. The stock should protrude approximately 2''.

2.Using a dial indicator, measure the

.006"), the excess runout should be elimi- nated.

3.Start by removing the chuck.

4.Remove the mounting bolts that hold the

5.Thread the back plate onto the spindle.

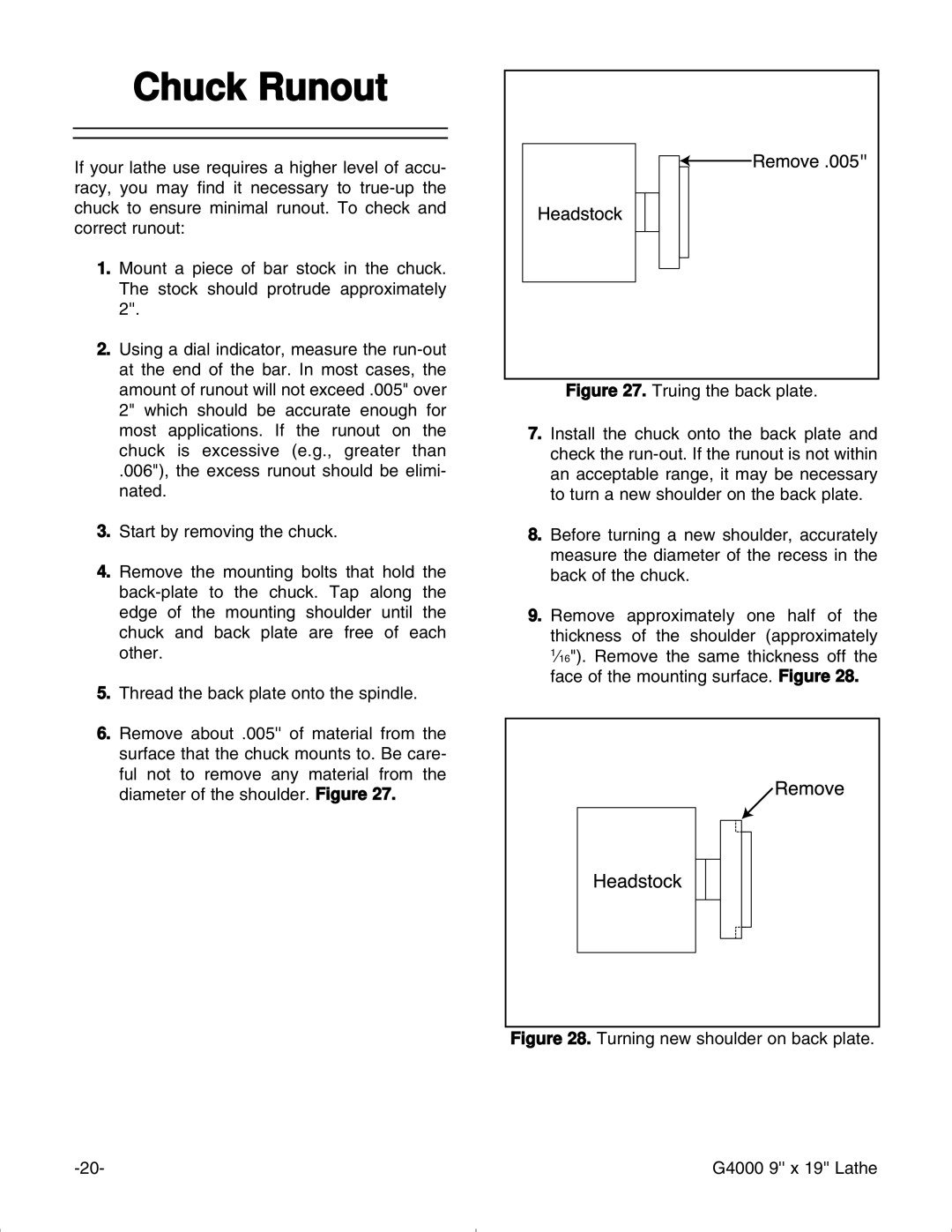

6.Remove about .005'' of material from the surface that the chuck mounts to. Be care- ful not to remove any material from the diameter of the shoulder. Figure 27.

Figure 27. Truing the back plate.

7.Install the chuck onto the back plate and check the run-out. If the runout is not within an acceptable range, it may be necessary to turn a new shoulder on the back plate.

8.Before turning a new shoulder, accurately measure the diameter of the recess in the back of the chuck.

9.Remove approximately one half of the thickness of the shoulder (approximately 1⁄16"). Remove the same thickness off the face of the mounting surface. Figure 28.

Figure 28. Turning new shoulder on back plate.

G4000 9'' x 19'' Lathe |