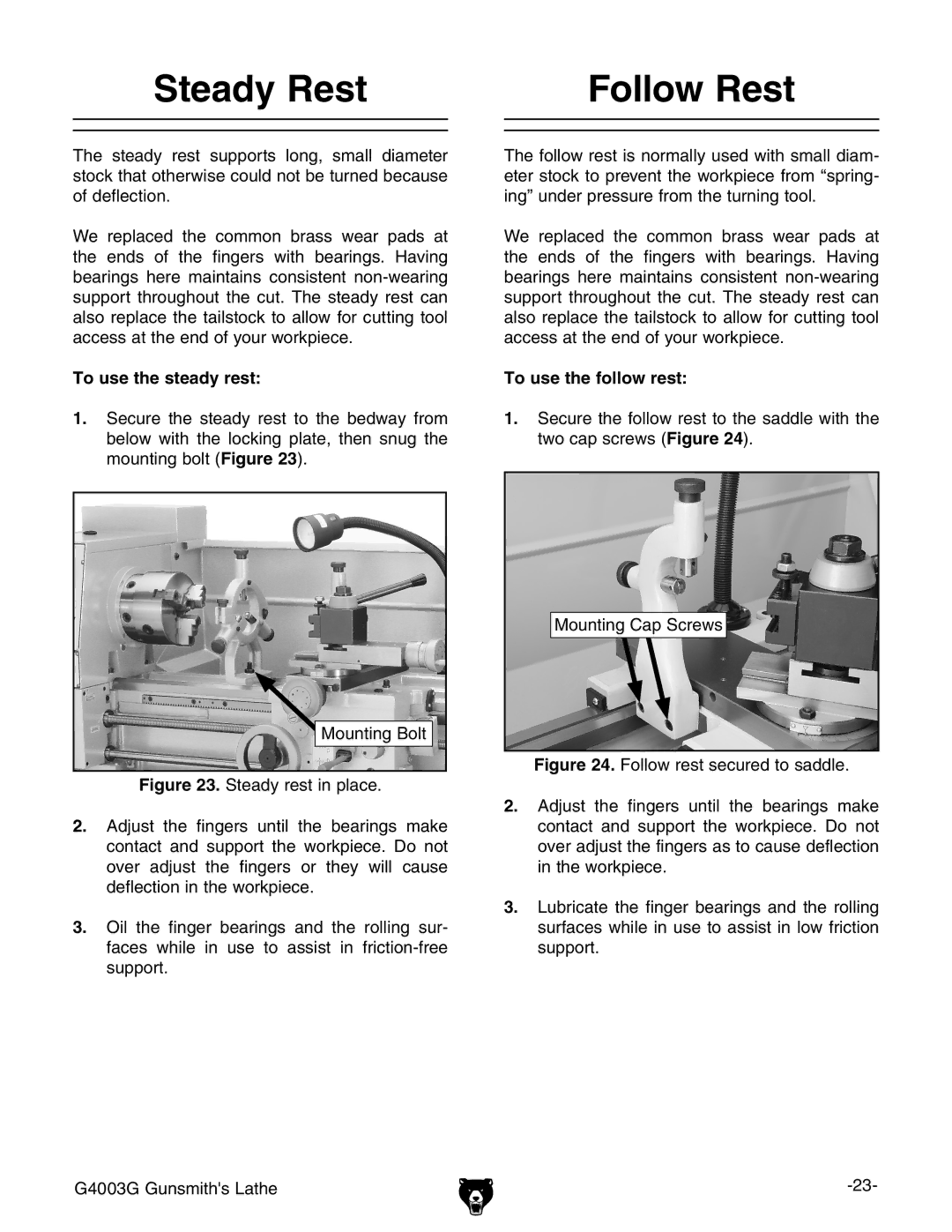

Mounting Bolt

The steady rest supports long, small diameter stock that otherwise could not be turned because of deflection.

We replaced the common brass wear pads at the ends of the fingers with bearings. Having bearings here maintains consistent non-wearing support throughout the cut. The steady rest can also replace the tailstock to allow for cutting tool access at the end of your workpiece.

To use the steady rest:

1.Secure the steady rest to the bedway from below with the locking plate, then snug the mounting bolt (Figure 23).

The follow rest is normally used with small diam- eter stock to prevent the workpiece from “spring- ing” under pressure from the turning tool.

We replaced the common brass wear pads at the ends of the fingers with bearings. Having bearings here maintains consistent non-wearing support throughout the cut. The steady rest can also replace the tailstock to allow for cutting tool access at the end of your workpiece.

To use the follow rest:

1.Secure the follow rest to the saddle with the two cap screws (Figure 24).

Figure 23. Steady rest in place.

2.Adjust the fingers until the bearings make contact and support the workpiece. Do not over adjust the fingers or they will cause deflection in the workpiece.

3.Oil the finger bearings and the rolling sur- faces while in use to assist in friction-free support.

G4003G Gunsmith's Lathe

Mounting Cap Screws

Figure 24. Follow rest secured to saddle.

2.Adjust the fingers until the bearings make contact and support the workpiece. Do not over adjust the fingers as to cause deflection in the workpiece.

3.Lubricate the finger bearings and the rolling surfaces while in use to assist in low friction support.

-23-