4.Place the chuck key in the

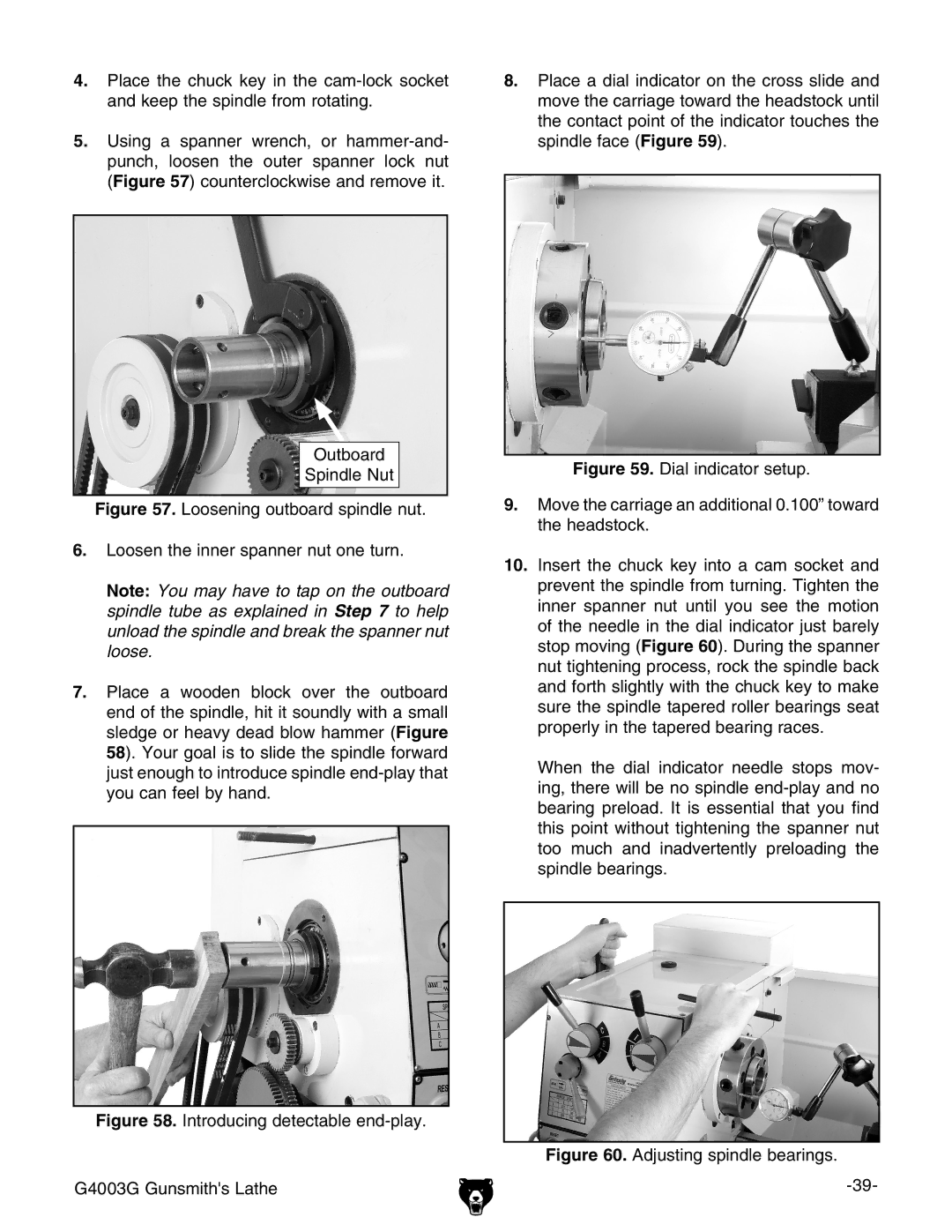

5.Using a spanner wrench, or

Outboard

Spindle Nut

Figure 57. Loosening outboard spindle nut.

6.Loosen the inner spanner nut one turn.

Note: You may have to tap on the outboard spindle tube as explained in Step 7 to help unload the spindle and break the spanner nut loose.