SECTION 6: MAINTENANCE

Basic Maintenance

Check for the following conditions and repair or replace when necessary:

•Loose mounting bolts and chuck.

•Worn switch or safety features.

•Worn or damaged cords or plug.

•Any other condition that could hamper the safe operation of this machine.

|

| Lubrication |

Take the time to wipe down and oil your lathe after | ||

use. Do not leave metal chips and cutting fluid on | ||

the ways. We recommend using ISO 68 or a gen- | ||

eral motor oil unless otherwise specified. | ||

Saddle, see Figure 47 | ||

Apply lubrication to the saddle through the two | ||

ball fittings on the top face of the saddle and | ||

one near the saddle handwheel. Make sure the | ||

oil level is | 3 | ⁄4 full as seen in the through the sight |

|

| |

glass. Change the oil for the first time after one | ||

month of operation, and then at six month inter- | ||

vals. Use the same oil as in the headstock. | ||

| ||

These slides are also supplied with ball fittings in | ||

their top surfaces and should be oiled the same | ||

as the saddle. | ||

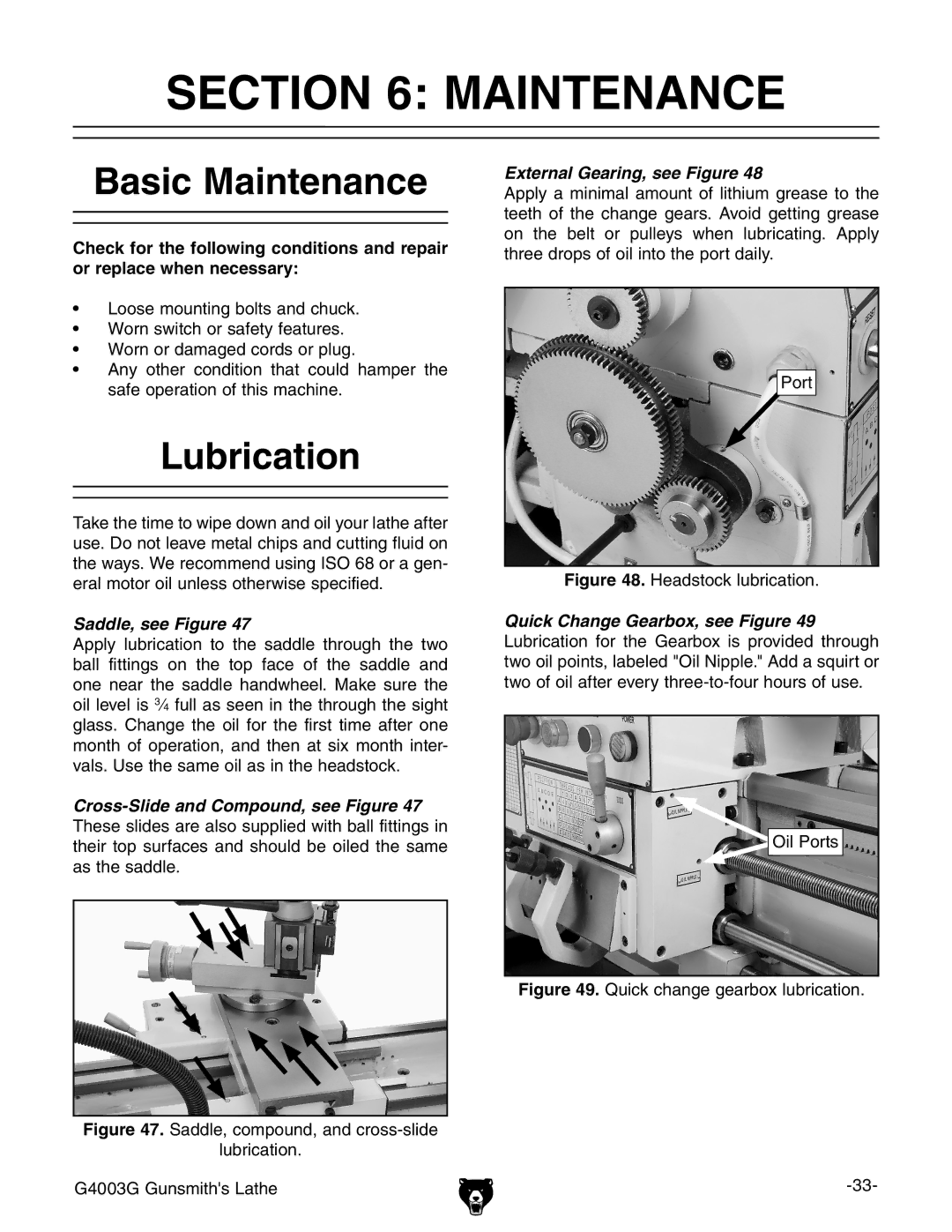

External Gearing, see Figure 48 Apply a minimal amount of lithium grease to the teeth of the change gears. Avoid getting grease on the belt or pulleys when lubricating. Apply three drops of oil into the port daily.

Port

Figure 48. Headstock lubrication.

Quick Change Gearbox, see Figure 49 Lubrication for the Gearbox is provided through two oil points, labeled "Oil Nipple." Add a squirt or two of oil after every

![]() Oil Ports

Oil Ports

Figure 49. Quick change gearbox lubrication.

Figure 47. Saddle, compound, and |

|

lubrication. |

|

G4003G Gunsmith's Lathe |