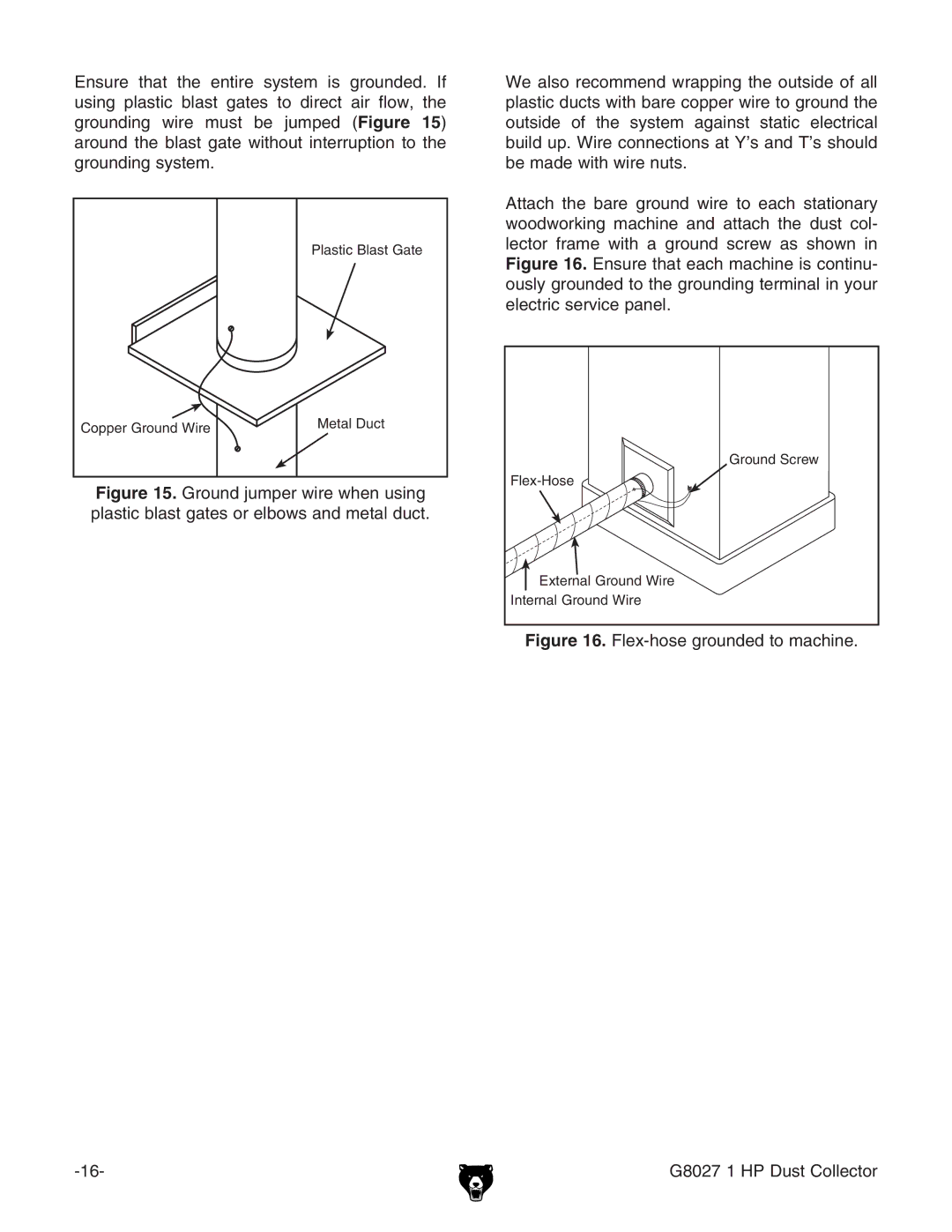

Ensure that the entire system is grounded. If using plastic blast gates to direct air flow, the grounding wire must be jumped (Figure 15) around the blast gate without interruption to the grounding system.

Plastic Blast Gate

Copper Ground Wire | Metal Duct |

|

Figure 15. Ground jumper wire when using plastic blast gates or elbows and metal duct.

We also recommend wrapping the outside of all plastic ducts with bare copper wire to ground the outside of the system against static electrical build up. Wire connections at Y’s and T’s should be made with wire nuts.

Attach the bare ground wire to each stationary woodworking machine and attach the dust col- lector frame with a ground screw as shown in Figure 16. Ensure that each machine is continu- ously grounded to the grounding terminal in your electric service panel.

Ground Screw

External Ground Wire

Internal Ground Wire

Figure 16. Flex-hose grounded to machine.

G8027 1 HP Dust Collector |