Creating Bends

The Model T10727 Slip Roll can easily create con-

Note: The method for creating a specific radius is

a

To create a bend in a workpiece:

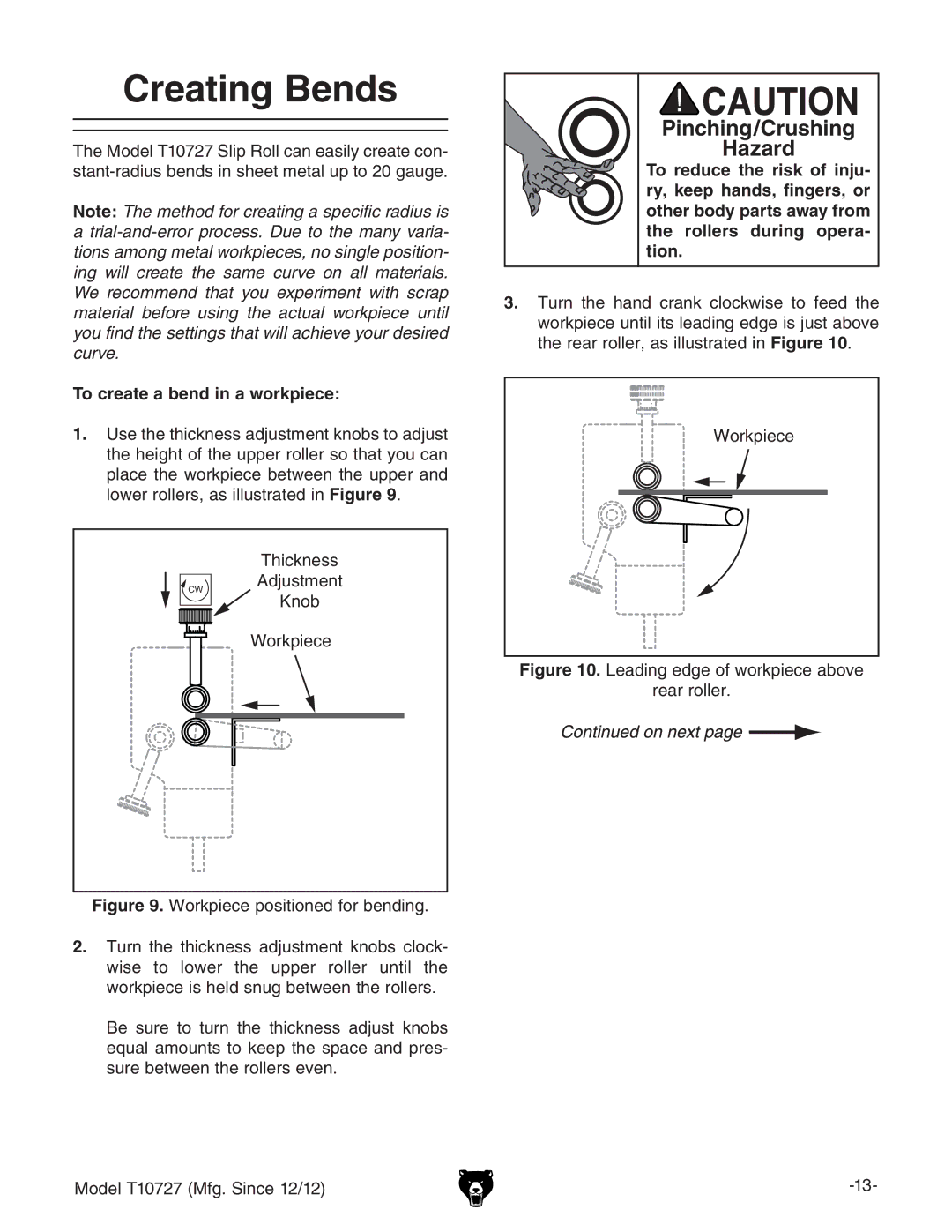

1.Use the thickness adjustment knobs to adjust the height of the upper roller so that you can place the workpiece between the upper and lower rollers, as illustrated in Figure 9.

| Thickness | |

CW | Adjustment | |

Knob | ||

| ||

| Workpiece |

Figure 9. Workpiece positioned for bending.

2.Turn the thickness adjustment knobs clock- wise to lower the upper roller until the workpiece is held snug between the rollers.

Be sure to turn the thickness adjust knobs equal amounts to keep the space and pres- sure between the rollers even.

Pinching/Crushing

Hazard

To reduce the risk of inju- ry, keep hands, fingers, or other body parts away from the rollers during opera- tion.

3.turn the hand crank clockwise to feed the workpiece until its leading edge is just above the rear roller, as illustrated in Figure 10.

Workpiece

Figure 10. Leading edge of workpiece above

rear roller.

Model T10727 (Mfg. Since 12/12) |