Once you have the necessary workpiece length, follow the steps below to create the cylinder.

Note: The method for creating a specific radius for a cylinder is a

To create a cylinder:

1.Use the thickness adjustment knobs to adjust the height of the upper roller so that you can place the workpiece between the upper and lower rollers, as illustrated in Figure 14.

CW |

Workpiece |

Figure 14. Workpiece positioned for creating a

cylinder.

2.Turn the thickness adjustment knobs clock- wise to lower the upper roller until the workpiece is held snug between the rollers.

Be sure to turn the thickness adjust knobs equal amounts to keep the space and pres- sure between the rollers even.

In the following step, always err on the side of making the cylinder too large rather than too small. It is easy to decrease the radius of a cylinder later, but very difficult to increase the radius.

3.rotate the hand crank clockwise to feed the workpiece until it is approximately half way through the rollers.

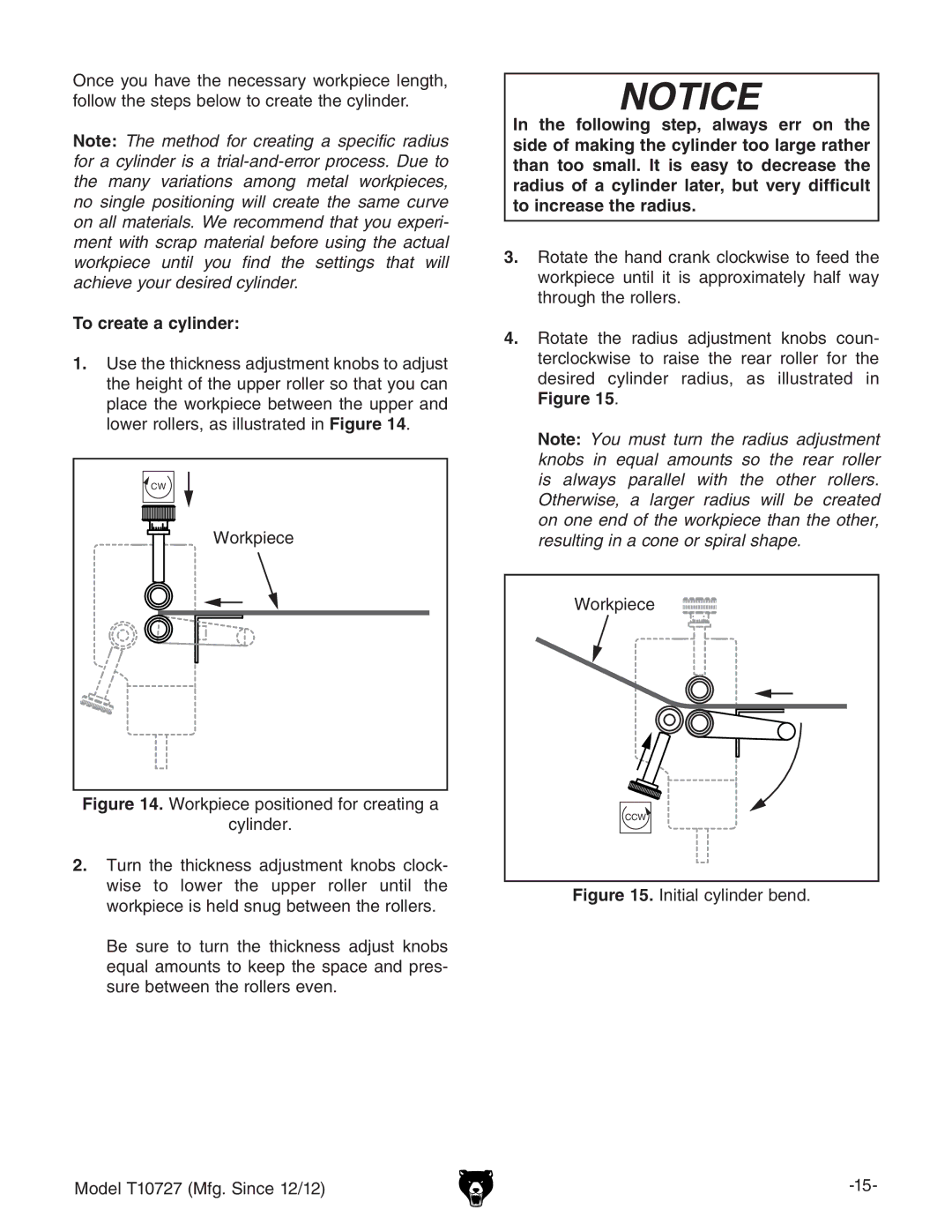

4.rotate the radius adjustment knobs coun- terclockwise to raise the rear roller for the desired cylinder radius, as illustrated in Figure 15.

Note: You must turn the radius adjustment knobs in equal amounts so the rear roller is always parallel with the other rollers. Otherwise, a larger radius will be created on one end of the workpiece than the other, resulting in a cone or spiral shape.

Workpiece |

CCW |

Figure 15. Initial cylinder bend.

Model T10727 (Mfg. Since 12/12) |