Bending Wire |

| Removing Workpiece |

|

|

|

|

|

|

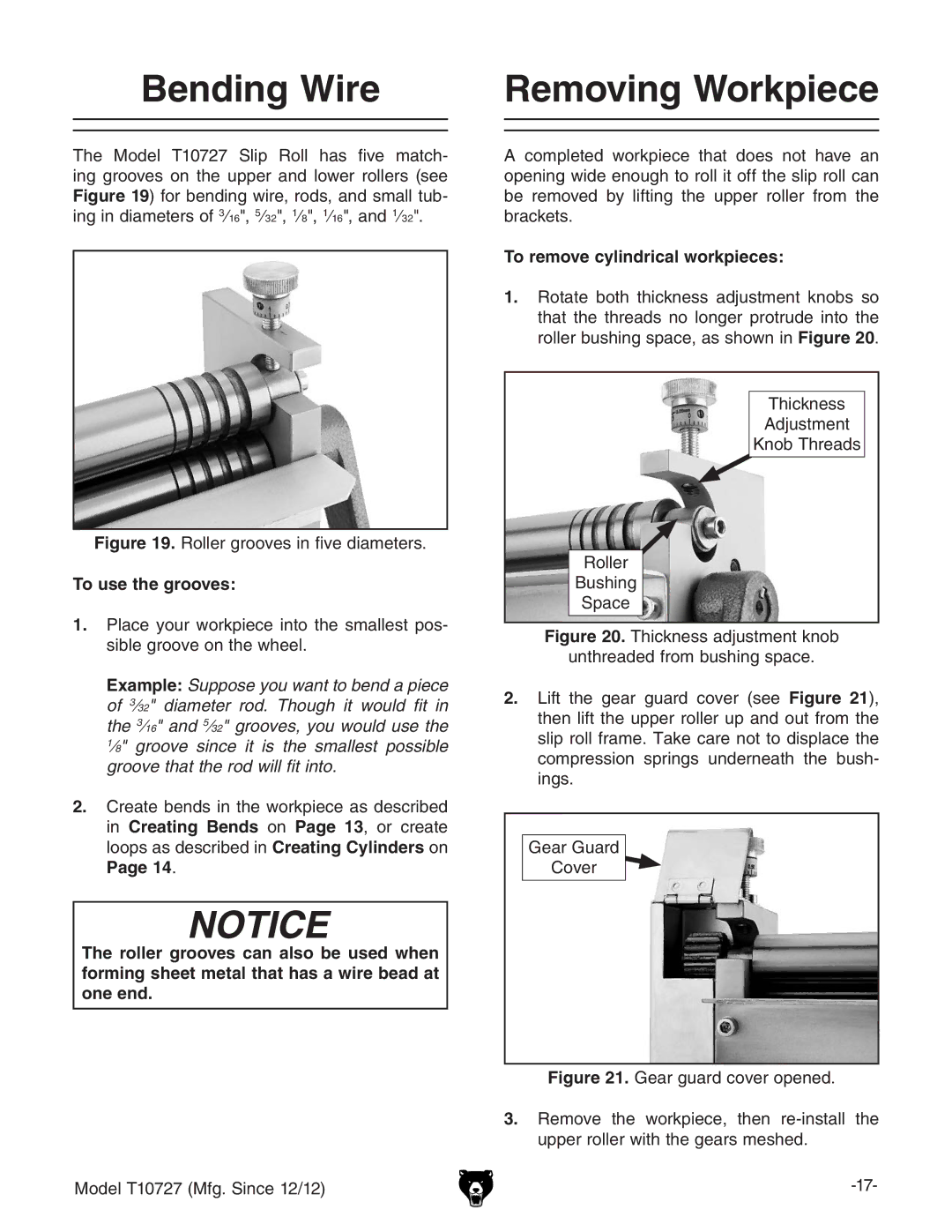

The Model T10727 Slip Roll has five match- ing grooves on the upper and lower rollers (see Figure 19) for bending wire, rods, and small tub- ing in diameters of 3⁄16", 5⁄32", 1⁄8", 1⁄16", and 1⁄32".

Figure 19. Roller grooves in five diameters.

To use the grooves:

1.place your workpiece into the smallest pos- sible groove on the wheel.

Example: Suppose you want to bend a piece of 3⁄32" diameter rod. Though it would fit in the 3⁄16" and 5⁄32" grooves, you would use the 1⁄8" groove since it is the smallest possible groove that the rod will fit into.

2.Create bends in the workpiece as described in Creating Bends on Page 13, or create loops as described in Creating Cylinders on Page 14.

The roller grooves can also be used when forming sheet metal that has a wire bead at one end.

Model T10727 (Mfg. Since 12/12)

A completed workpiece that does not have an opening wide enough to roll it off the slip roll can be removed by lifting the upper roller from the brackets.

To remove cylindrical workpieces:

1.rotate both thickness adjustment knobs so that the threads no longer protrude into the roller bushing space, as shown in Figure 20.

Thickness

Adjustment

Knob Threads

Roller

Bushing

Space