SECTION 6: SERVICE

Review the troubleshooting and procedures in this section if a problem develops with your machine. If you need replacement parts or additional help with a procedure, call our Technical Support at (570)

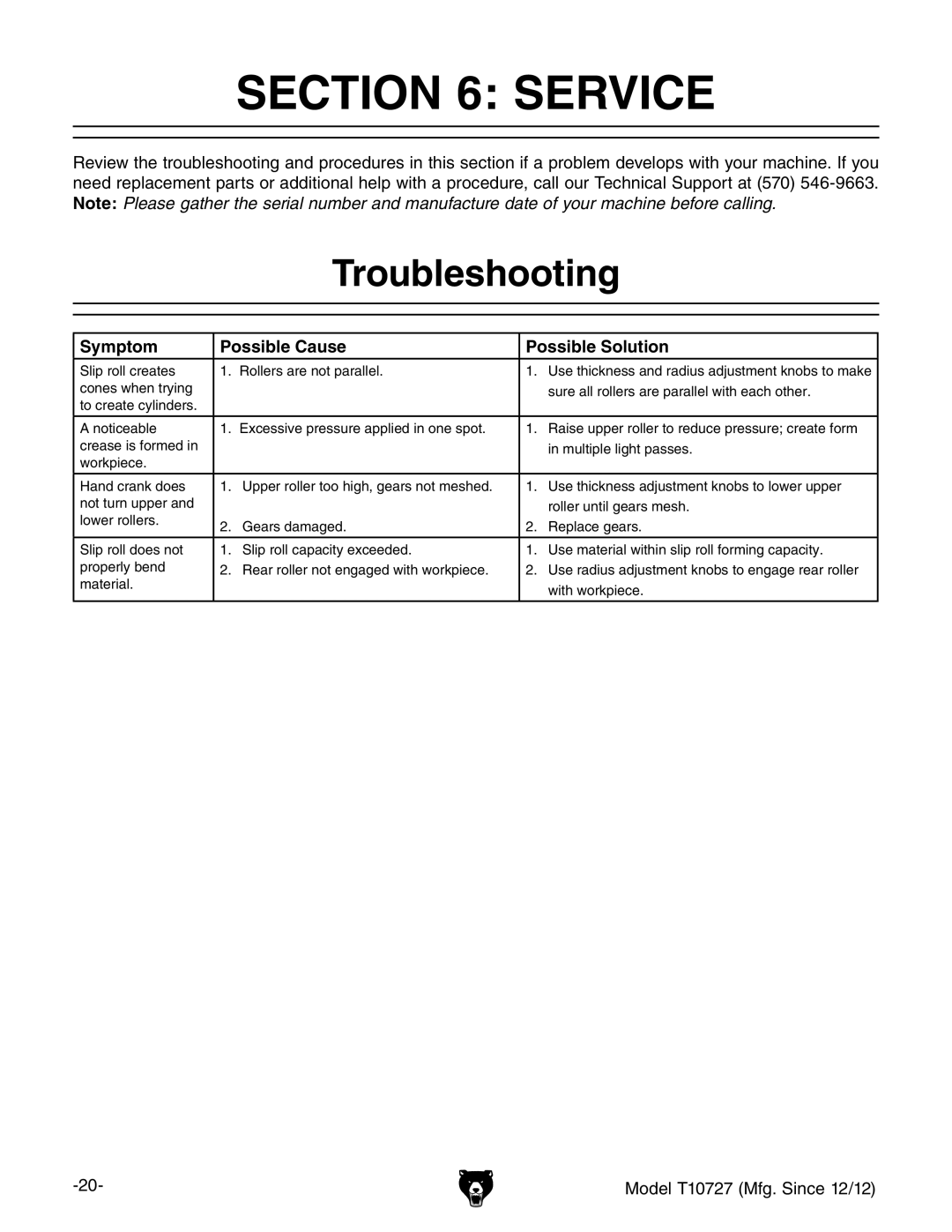

Troubleshooting

Symptom | Possible Cause | Possible Solution | ||

Slip roll creates | 1. | Rollers are not parallel. | 1. | Use thickness and radius adjustment knobs to make |

cones when trying |

|

|

| sure all rollers are parallel with each other. |

to create cylinders. |

|

|

|

|

A noticeable | 1. | Excessive pressure applied in one spot. | 1. | raise upper roller to reduce pressure; create form |

crease is formed in |

|

|

| in multiple light passes. |

workpiece. |

|

|

|

|

Hand crank does | 1. | Upper roller too high, gears not meshed. | 1. | Use thickness adjustment knobs to lower upper |

not turn upper and |

|

|

| roller until gears mesh. |

lower rollers. | 2. | gears damaged. | 2. | replace gears. |

| ||||

|

|

|

|

|

Slip roll does not | 1. | slip roll capacity exceeded. | 1. | Use material within slip roll forming capacity. |

properly bend | 2. | rear roller not engaged with workpiece. | 2. | Use radius adjustment knobs to engage rear roller |

material. |

|

|

| with workpiece. |

|

|

|

| |

|

|

|

|

|

Model T10727 (Mfg. Since 12/12) |