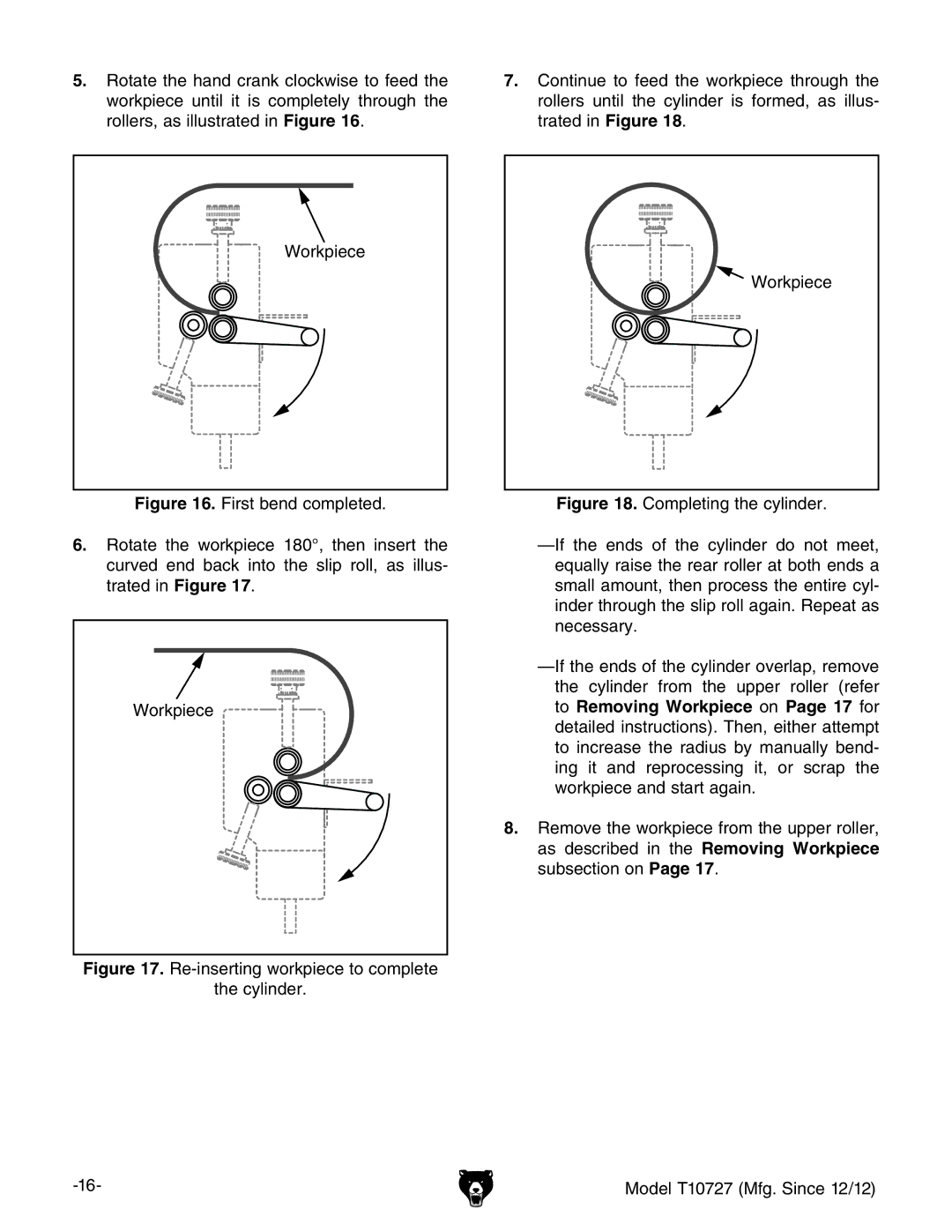

5.Rotate the hand crank clockwise to feed the workpiece until it is completely through the rollers, as illustrated in Figure 16.

7.Continue to feed the workpiece through the rollers until the cylinder is formed, as illus- trated in Figure 18.

Workpiece